Full-function type bolt screwing shaft controller

A controller and tightening shaft technology, which is applied in non-electric variable control, control/regulation systems, and simultaneous control of multiple variables, etc., can solve the problem that the control system cannot satisfy the real-time performance of bolt tightening torque and tightening angle, and tightening accuracy. Bolt damage , the overall response speed is slow, etc., to improve assembly quality, overcome false torque, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

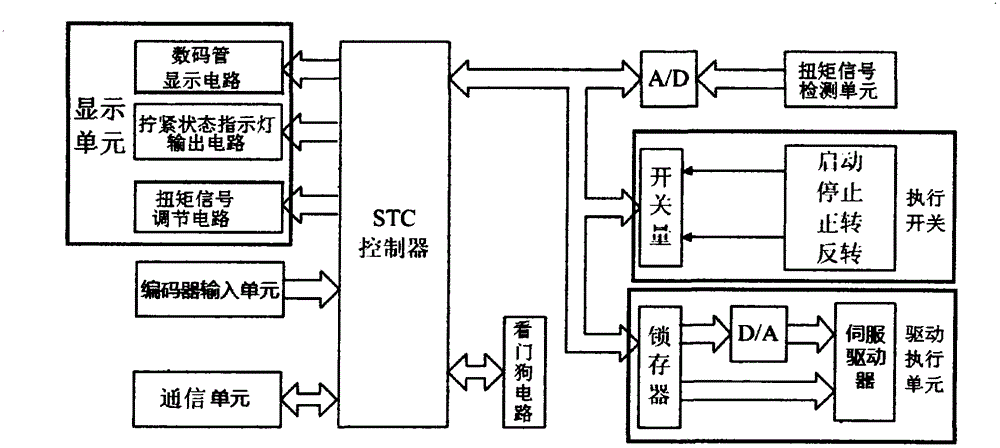

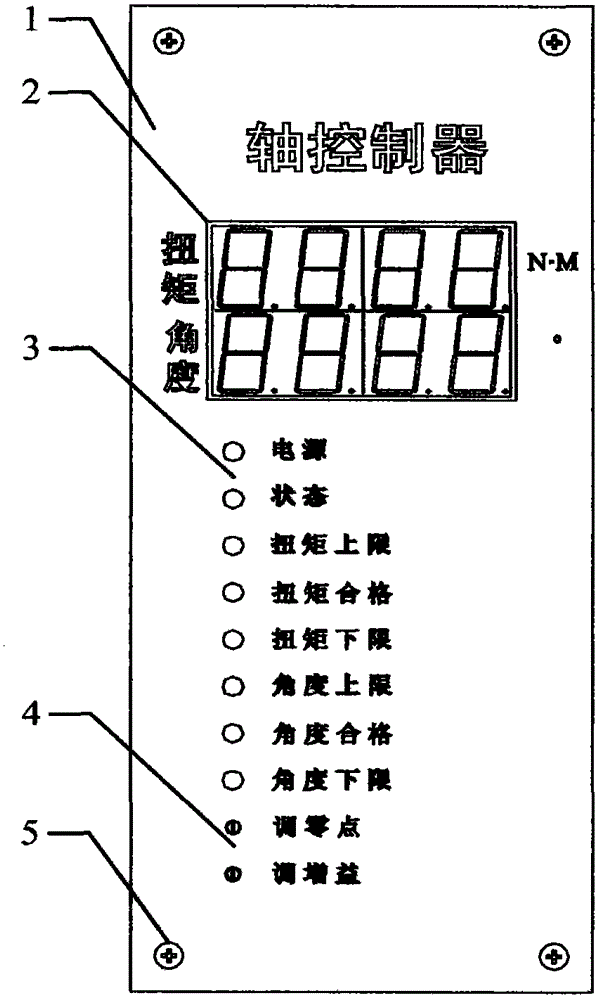

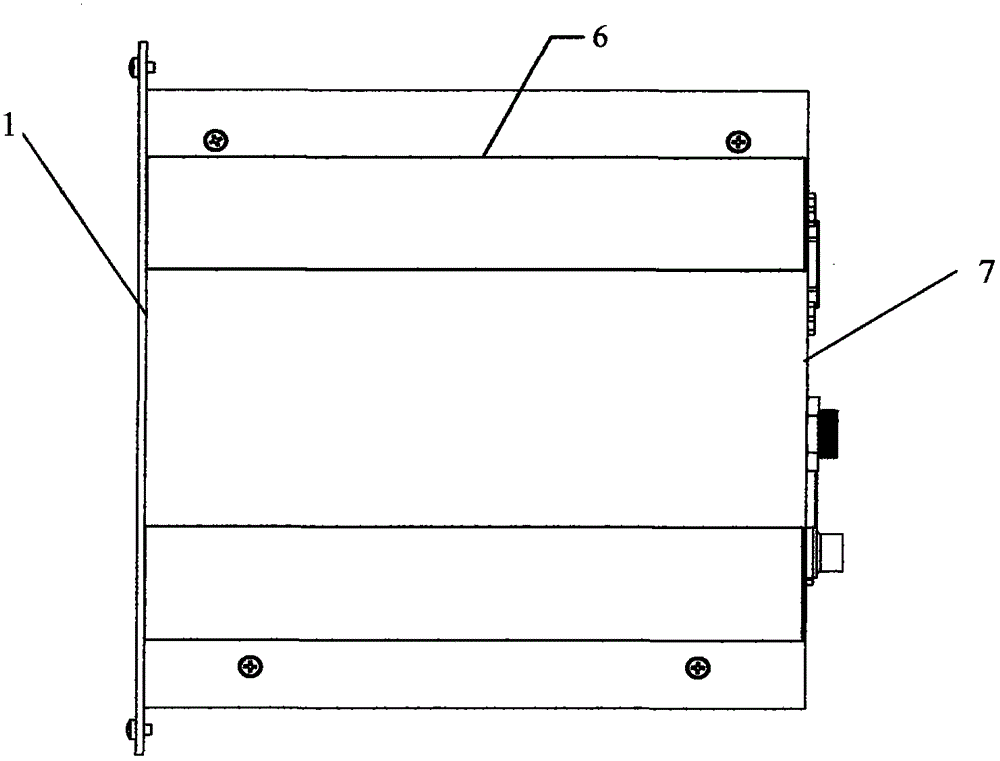

[0033] The invention provides a full-featured bolt tightening axis controller, in which each bolt tightening axis is connected to a bolt tightening axis controller, and its structure is as follows figure 1 shown, which includes:

[0034] STC controller, used for signal input detection, output control and data processing;

[0035] The torque signal detection unit is used to detect the torque on the tightening shaft when the bolt is tightened;

[0036] an execution switch, used to send an instruction signal for performing a tightening action to the STC controller;

[0037] Drive the execution unit, receive the signal from the STC controller, and instruct and control the servo motor to drive the tightening shaft to complete the tighteni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com