Electromagnet coil framework

An electromagnet coil and coil skeleton technology, applied in the field of electromagnets, can solve the problems of short circuit of the coil, paralysis of the hydraulic system, low protection level, etc., so as to reduce the probability of entering the coil, increase the protection level, and avoid the effect of paralysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

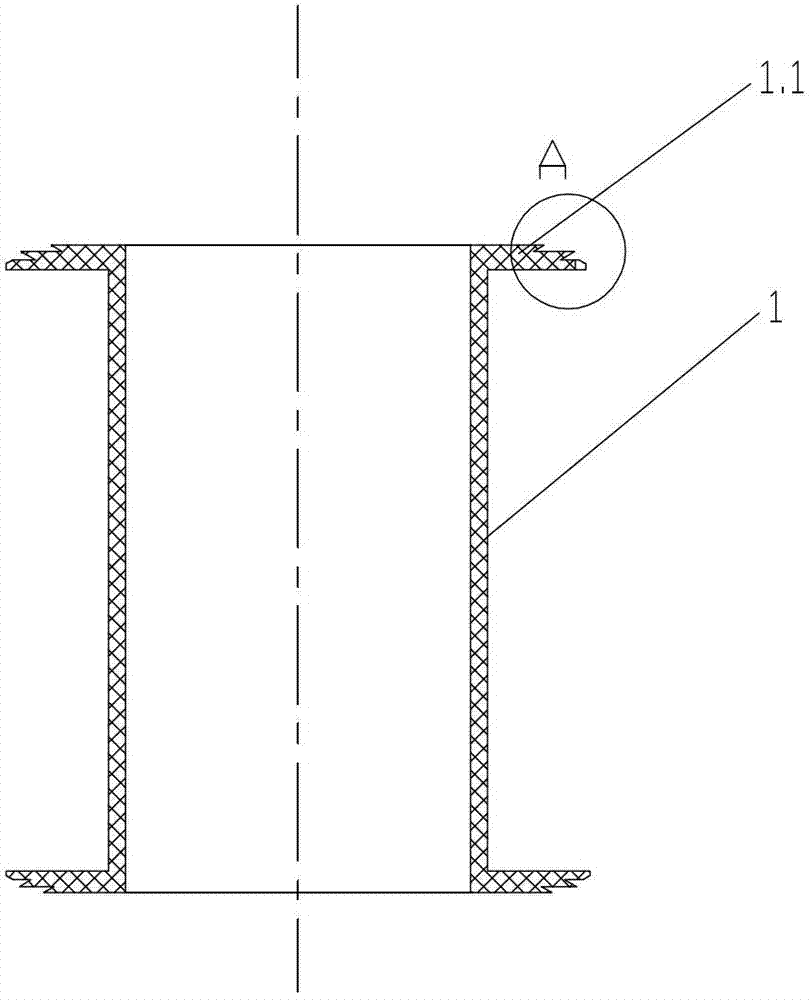

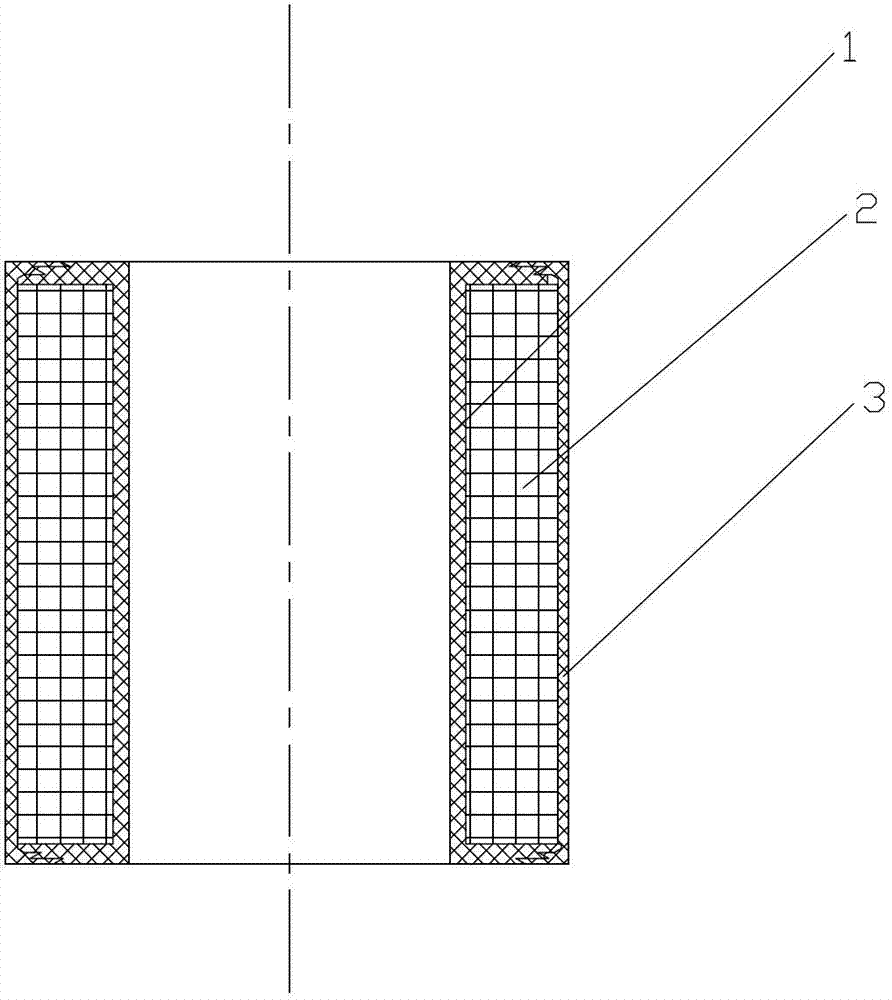

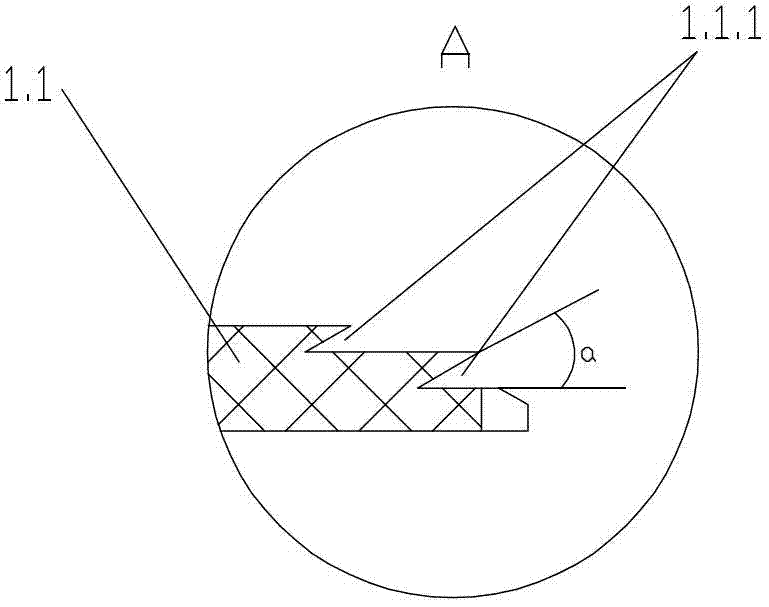

[0021] Such as figure 1 , figure 2 , image 3 As shown, the electromagnet bobbin of the present invention includes a bobbin body 1 with a central hole, two ends of the bobbin body 1 are respectively provided with radial protruding rings 1.1, and the outer wall of each radial protruding ring 1.1 At least one radial annular groove 1.1.1 is provided.

[0022] The number of said annular grooves 1.1.1 in this embodiment is two and distributed axially.

[0023] The radial convex ring 1.1 is provided with two steps, and each annular groove 1.1.1 is provided on a corresponding step.

[0024] The included angle a between the side wall and the bottom surface of the annular groove 1.1.1 is 20-70 degrees, that is to say, the single side cross section of the annular groove 1.1.1 is triangular.

[0025] The included angle a between the side wall and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com