Semiconductor packaging method for forming two-sided electromagnetic shielding layer as well as construction thereof

A technology of electromagnetic shielding layer and packaging method, which is applied in semiconductor/solid-state device manufacturing, semiconductor device, semiconductor/solid-state device components and other directions, can solve the problems of insufficient carrying capacity of substrate mother sheet 110, plated through hole 117 covering connection, etc., To achieve the effect of the best side electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

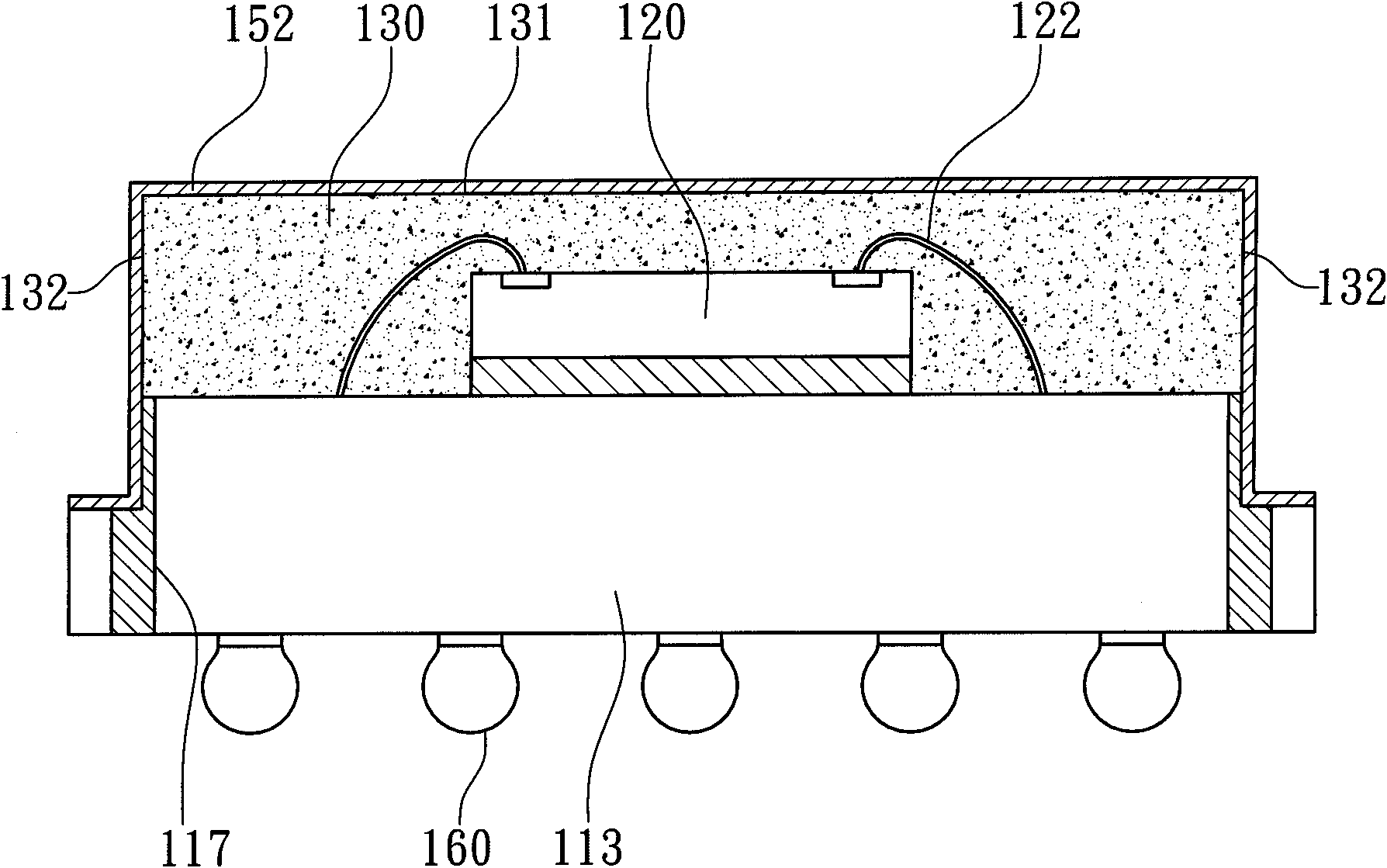

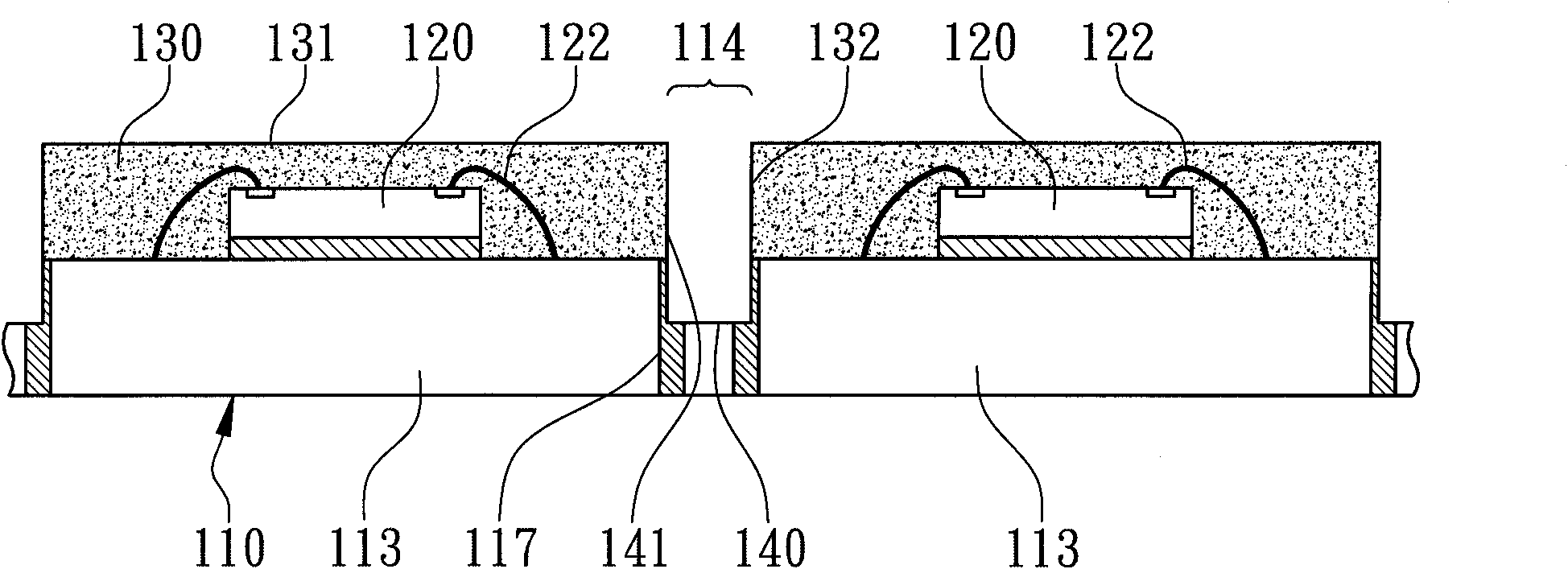

[0057] According to the first embodiment of the present invention, a semiconductor packaging method and structure for forming a double-sided electromagnetic shielding layer are illustrated in Figure 3A to Figure 3I A schematic cross-sectional view of each step to form an element, and a detailed description of each step is as follows.

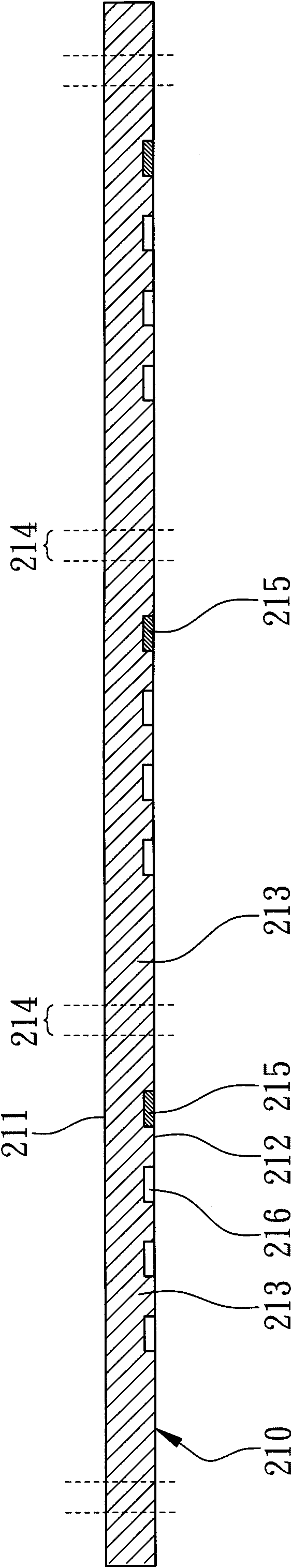

[0058] First, if Figure 3A and Figure 4 As shown, a mother substrate 210 is provided, and the mother substrate 210 has an upper surface 211 and a lower surface 212 . The base substrate 210 can be a strip-shaped printed circuit board or a strip-shaped flexible circuit board, with a single-layer or multi-layer circuit structure inside. The upper surface 211 is used for chip placement, and the lower surface 212 is a surface to be bonded to the outer surface of the semiconductor package structure. The lower surface 212 can be provided with a plurality of external pads 216 arranged in a matrix. The substrate master 210 includes a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com