Foundry mixes containing carbonate salts and their uses

A technology of mixtures and carbonates, applied in the direction of casting molding equipment, molds, mold components, etc., can solve the problems of reducing mold/core strength, increasing metal penetration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

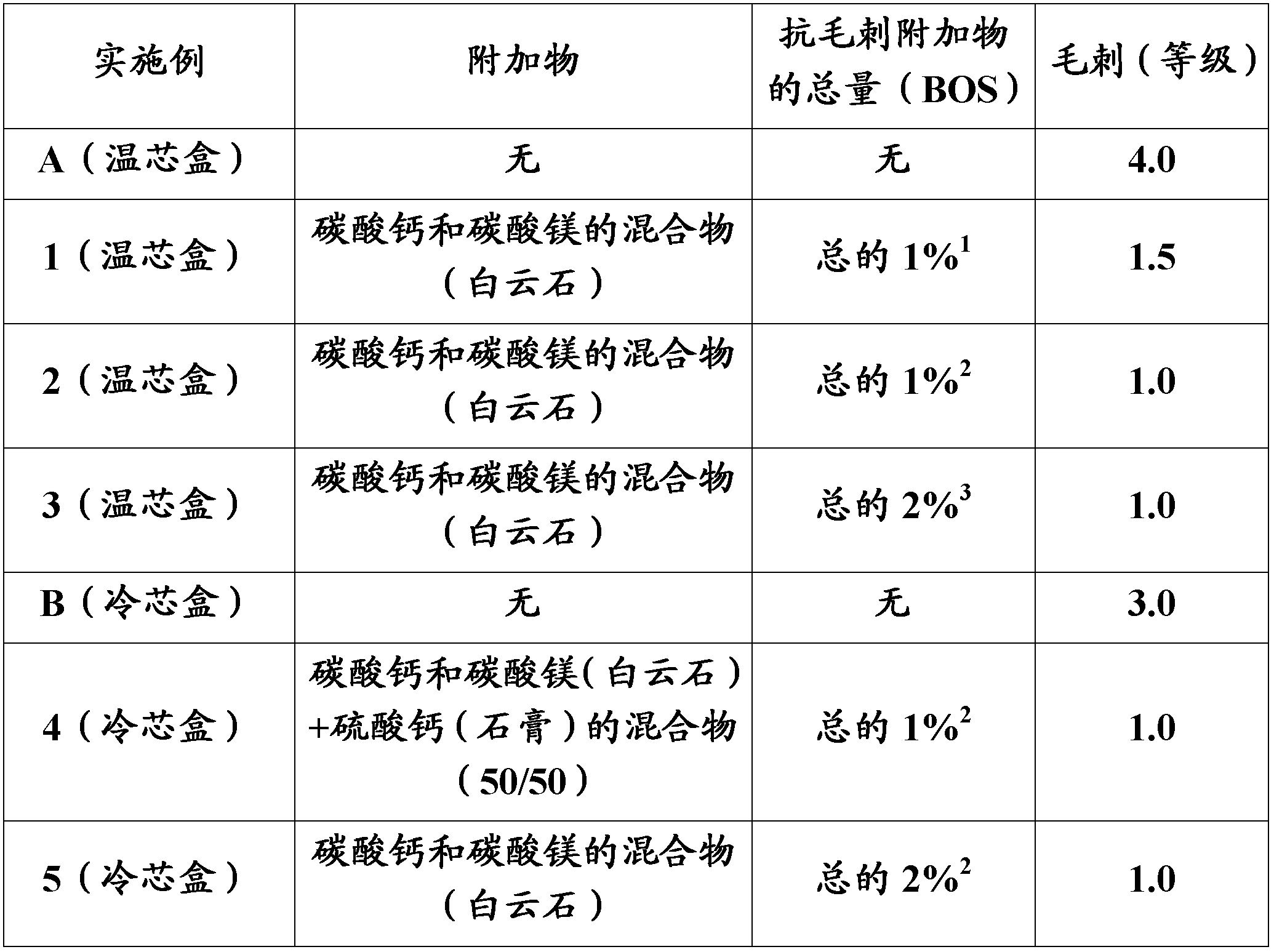

Examples

Embodiment B

[0026] In Example B (comparative example) and Example 4-5, the test core was prepared by the cold box process in the following manner: Wedron 540 quartz sand and 1.0% TKW 10 / 20 phenolic urethane binder (a two-component phenolic urethane binder sold by Ashland Inc., the ratio of component I and component II is 1:1) and the sand addition in Table 1 The mixture is mixed with the amount, and the mixture is blown into a core box with a 2" cylinder and a 2" high cavity, and the core is cured with TEA catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com