Mechanical cleaning hog house

A mechanical cleaning and pig house technology, applied in the field of animal husbandry, can solve the problems of endangering the health of animals and breeders, high labor intensity, and large investment, so as to prevent pigs from suffering from various diseases, prevent pollution and stench, save energy and reduce waste. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

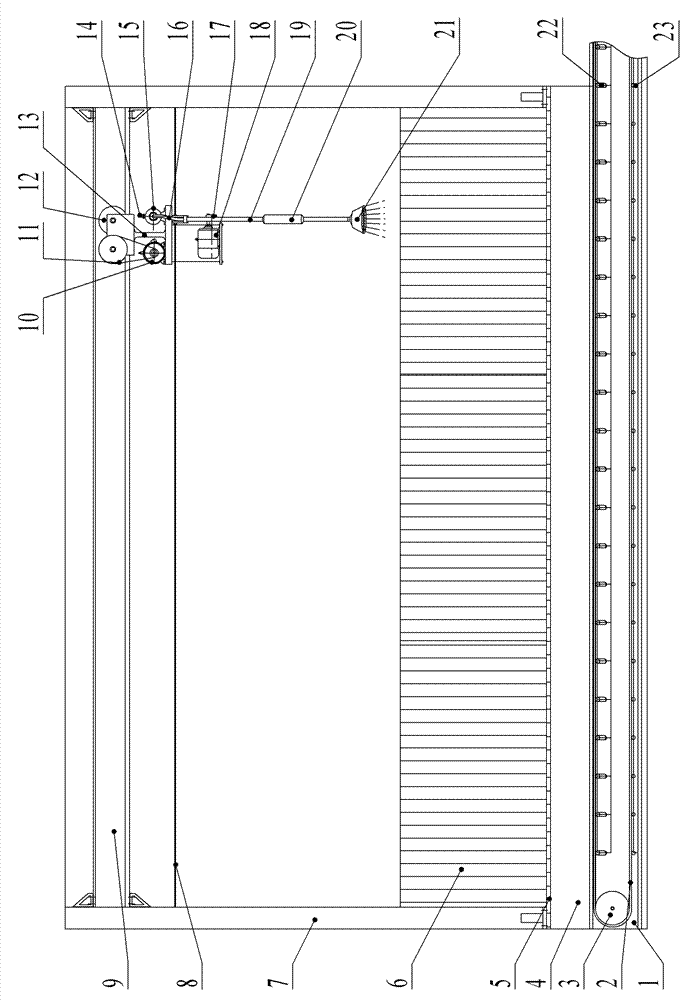

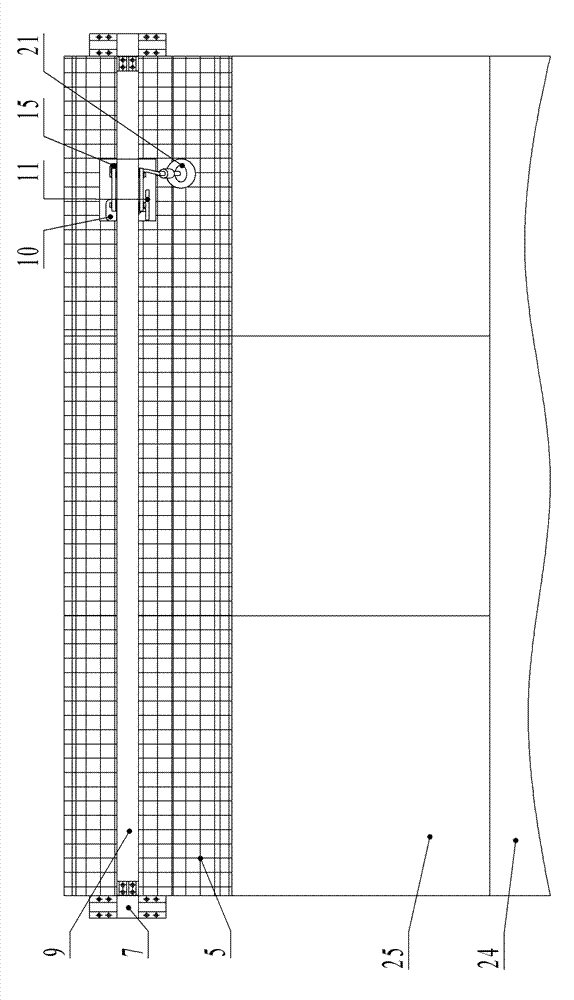

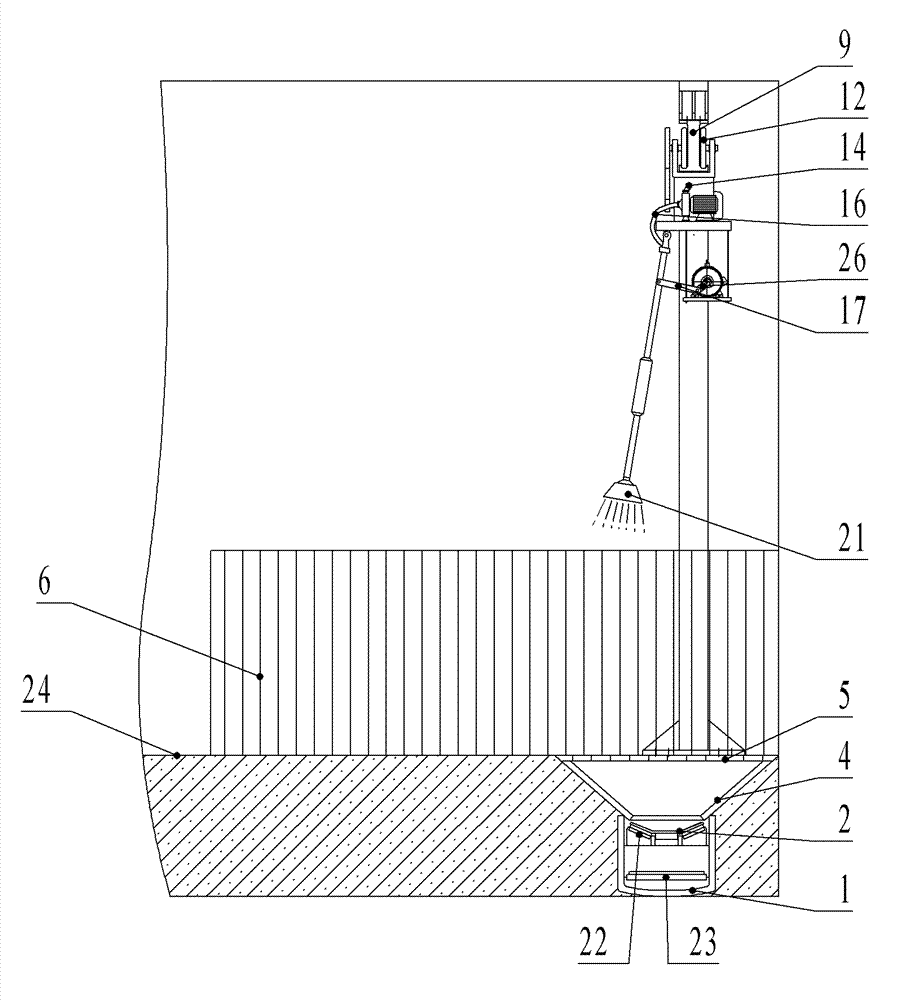

[0011] Figure 1 to Figure 3 Shown mechanical cleaning pigsty, along the length direction of pigsty, be provided with a row of some pens formed by 6 circles of guardrails, walkway 24 is left beside the pens, and living area 25 and excretion area are arranged in each pens circle, The living area 25 is adjacent to the walkway 24, and the floor of the excretion area is a slatted floor 5 made of stainless steel. Below the excretion area, a sufficiently wide and deep ditch is dug along the length direction of the whole row of pens. The body is provided with a water ditch 1 made of reinforced concrete, and the water ditch 1 extends from the first pen to the biogas digester away from the piggery after passing through each pen; the water ditch 1 is provided with a belt conveyor, and the belt conveyor The output end is connected to the entrance of the septic ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com