Humidification equipment for isenthalpic annealing furnace protective gas

A humidification device and protective gas technology, which is applied in the field of humidification treatment device for decarburization protective gas on the heat treatment surface of silicon steel, can solve the problems of large equipment, large area and low control accuracy, and achieves fast humidification treatment speed and energy utilization rate. High, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

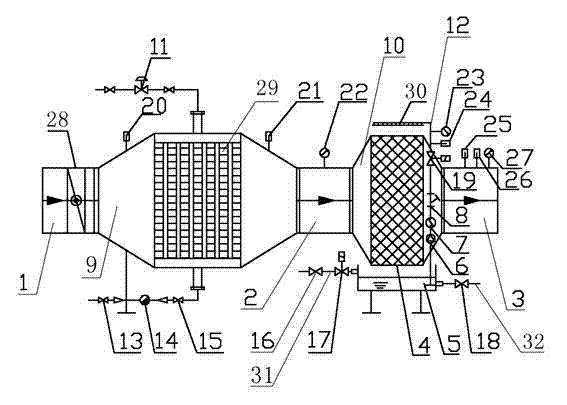

[0020] See attached figure 1 , an isenthalpy type annealing furnace protective gas humidification device according to the present invention includes a heating chamber 9 that penetrates back and forth and a humidification chamber 10 that also penetrates back and forth. The humidification chamber 10 is provided with an organic polymer humidification film 4, and the humidification chamber The front end of the chamber 10 communicates with the heating chamber 9 through the connecting pipe 2, the rear end is connected to the air outlet pipe 3, and the other end of the heating chamber is connected to the intake pipe 1, and a damper 28 that can adjust the intake air volume is arranged between the heating chamber and the intake pipe , the interfaces at both ends of the humidification chamber 10 and the heating chamber 9 are bell mouths that are wide inside and narrow outside.

[0021] The humidifying membrane 4 is equipped with a set of water replenishing device, which includes a water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com