Dyeing method using accelerating, fixation and chelation dispersing aid of active dye

A reactive dye, chelating and dispersing technology, applied in the field of dyeing and finishing, can solve the problems of increasing difficulty in wastewater treatment and complicated procedures, and achieve the solution of increasing difficulty in wastewater treatment, simple process, good wash fastness and rubbing fastness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

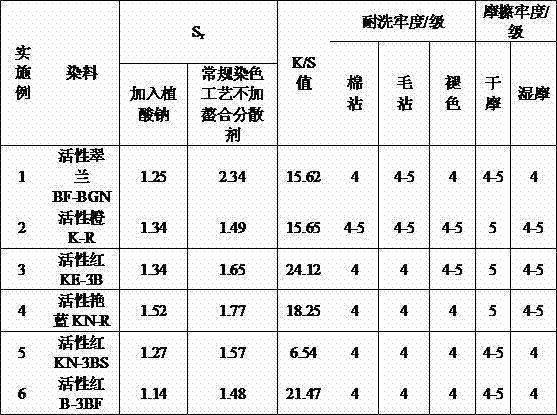

Examples

Embodiment 1

[0013] Dyeing method using reactive dyes to accelerate dyeing, color fixation and chelating dispersing auxiliaries, adopt exhaust dyeing process to dye cotton fabrics, the process flow is: first dissolve dyes and sodium phytate, enter dyeing at 30°C, liquor ratio 1:100, then Raise the temperature to 60°C at a heating rate of 1°C / min, keep it warm for 60 minutes, and finally wash with water, soap, wash with water, and dry.

[0014] The dye solution prescription is as follows:

[0015] Active Greenlandia BF-BGN 2% owf

[0016] Sodium Phytate 120g / L

Embodiment 2

[0018] Using the dyeing method of reactive dyes to accelerate dyeing, color fixation and chelating dispersing auxiliaries, the cotton fabric is dyed by exhaust dyeing process. The process is: first dissolve the dye and sodium phytate, enter the dyeing at 40°C, the liquor ratio is 1:60, and then Raise the temperature to 90°C at a heating rate of 1.5°C / min, keep it warm for 40 minutes, and finally wash with water, soap, wash with water, and dry.

[0019] The dye solution prescription is as follows:

[0020] Active Orange K-R 5% owf

[0021] Sodium Phytate 150g / L

Embodiment 3

[0023] The dyeing method uses reactive dyes to accelerate dyeing, color fixation and chelating dispersing auxiliaries, and adopts the exhaust dyeing process to dye silk fabrics. The process flow is: first dissolve the dye and sodium phytate, enter the dyeing at 30 °C, the liquor ratio is 1:20, and then Raise the temperature to 80°C at a heating rate of 2°C / min, keep it warm for 40 minutes, and finally wash with water, soap, wash with water, and dry.

[0024] The dye solution prescription is as follows:

[0025] Reactive Red KE-3B 3% owf

[0026] Sodium Phytate 30g / L

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com