Memory device with external chip controller and manufacturing method of memory device

A manufacturing method and memory technology, applied in the direction of static memory, digital memory information, semiconductor/solid-state device manufacturing, etc., can solve the problems of increased process cost and expensive production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the invention will cooperate with the illustrated Figure 1 to Figure 10 For details in the following.

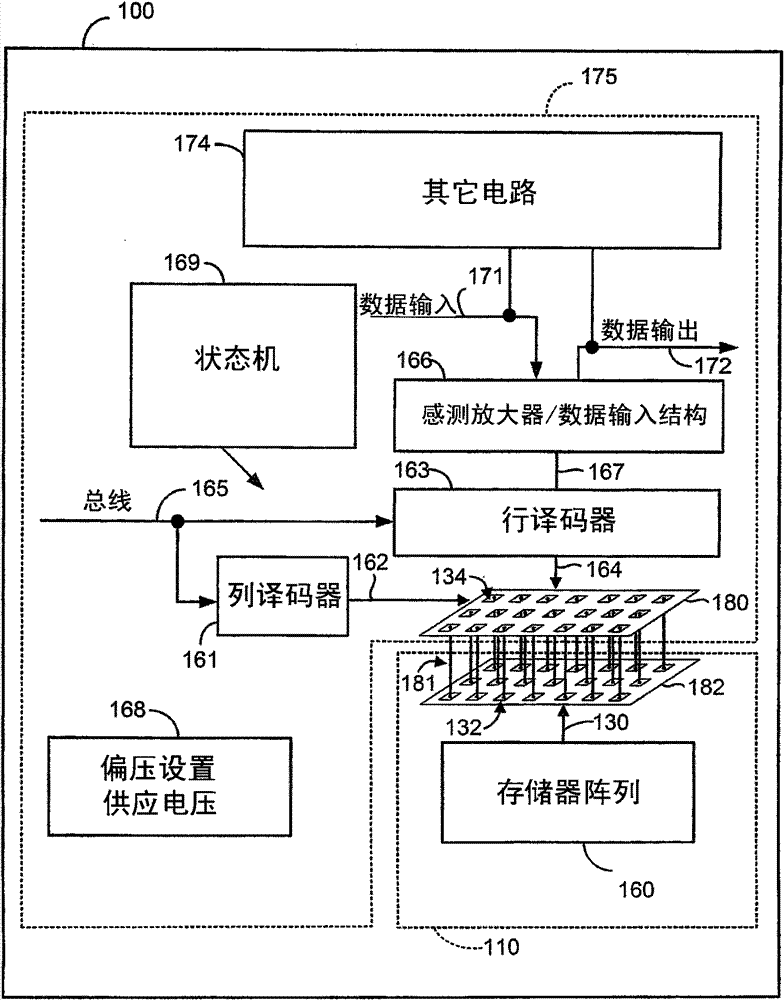

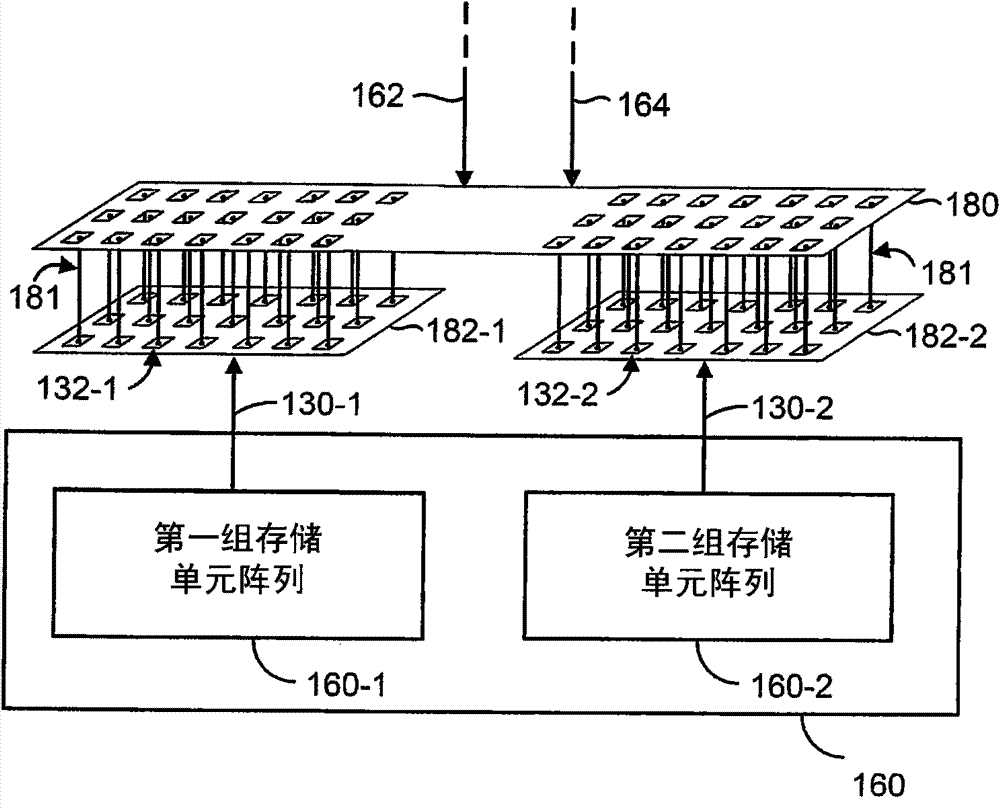

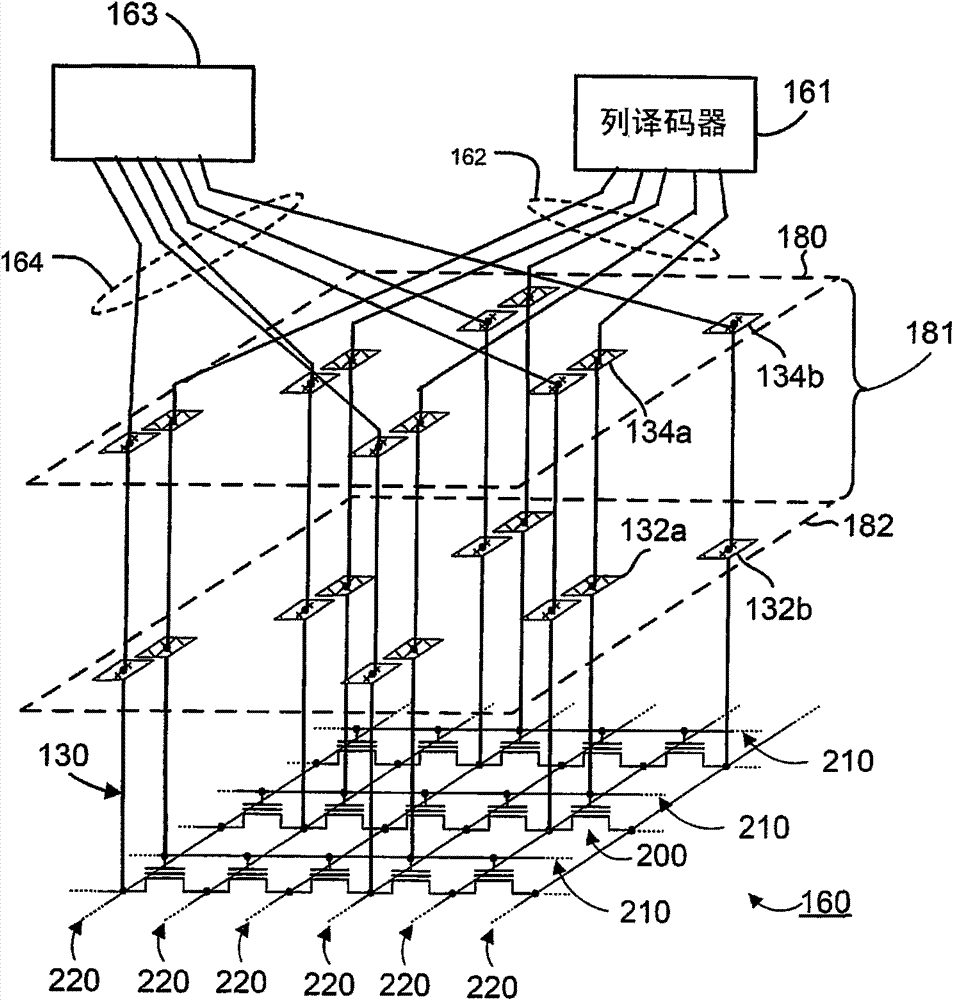

[0041] figure 1 A block diagram of a simplified integrated circuit memory device 100 is shown. The integrated circuit memory device 100 includes a memory circuit 100 and a peripheral circuit 175. The memory circuit and the peripheral circuit described here are physically separated from the device 100. on different layers, and are connected to each other through an interconnection interface 181 . The term “joined” or “joining” used herein means that the memory circuit 110 is attached, fixed, or otherwise physically connected to the peripheral circuit 175 . This term covers that the memory circuit 110 is directly attached to the peripheral circuit 175, such as through bonding. The term also covers that the memory circuit 110 is configured to be indirectly connected to the peripheral circuit 175 through an interposer unit or element between the memory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com