Pad structure of integrated circuit package

A technology of integrated circuits and pads, which is applied in the field of connection pad structures and pad structures, and can solve problems such as short circuit faults, solder inability to overflow, and difficulty in meeting assembly and welding process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

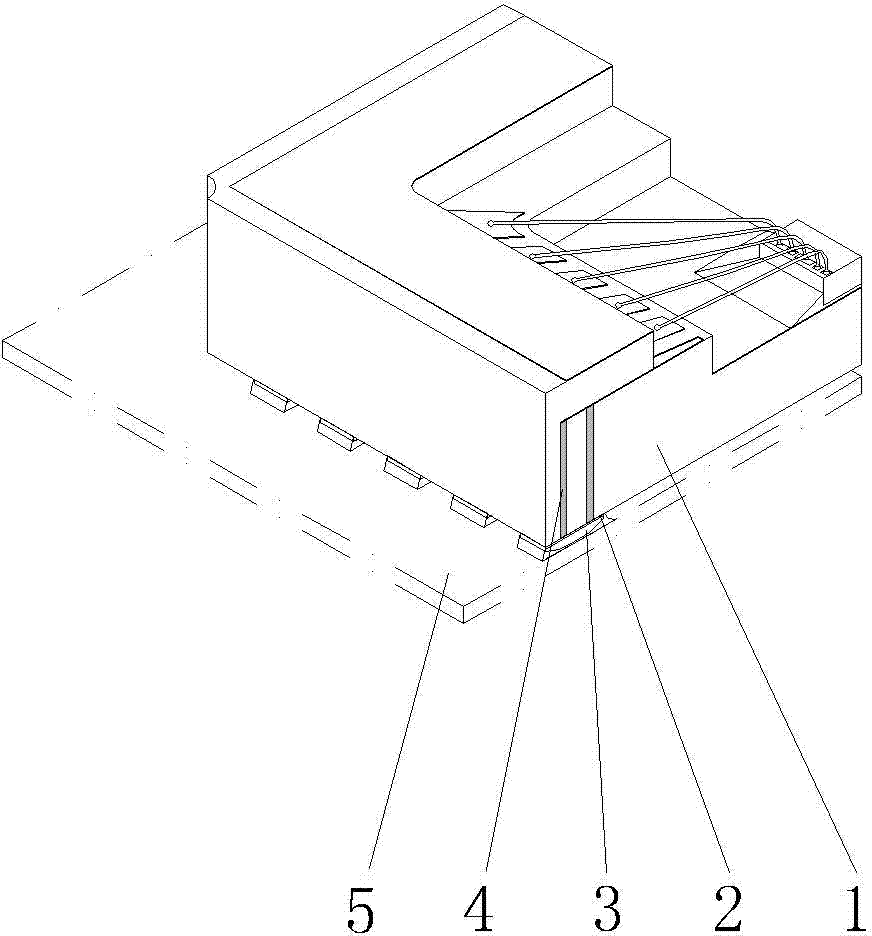

[0011] figure 1 A specific embodiment of the pad structure of an integrated circuit package of the present invention is given, which includes a ceramic shell 1, a pad 2, a bump 3 and an interconnection blind hole 4, and the internal wiring of the ceramic shell 1 passes through the interconnection blind hole 4 is connected to the pad 2 to meet the requirements for fine-pitch interconnection; the bump 3 is located on the pad 2 and protrudes from the surface of the ceramic shell 1, and various solder bumps 3 can be made on the surface of the pad 2, or can be made on the surface of the pad 2 Various metal protrusions 3 are sintered or welded on the pad 2. The height of the protrusions 3 protruding from the surface of the ceramic shell 1 is not limited. The height of the protrusions is preferably 0.1-0.5 mm, preferably 0.15 mm-0.25 mm. The surface of the ceramic case 1 is generally flush with the surface of the pad 2, so the height of the protrusion 3 protruding from the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com