Acoustic sensor and microphone

A sound sensor and diaphragm technology, applied in the direction of sensors, microphone structure associations, loudspeakers, etc., can solve the problems of reducing the size and difficulty of microphones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

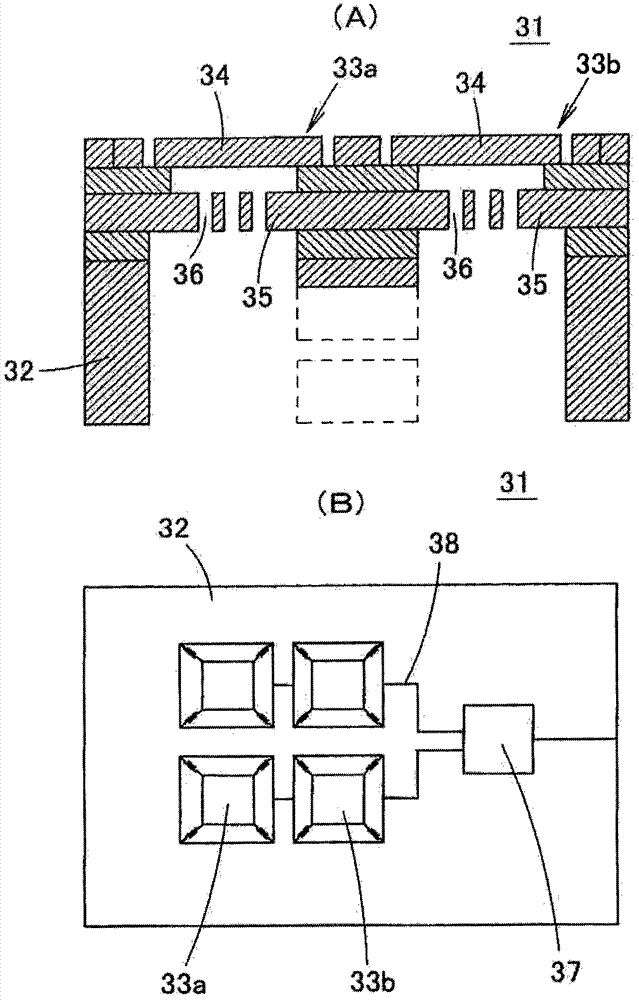

[0083] The structure of the sound sensor in the example 1 of the present invention will refer to the appended Figures 4 to 6 Be explained. attached Figure 4 is a sectional view of the acoustic sensor 41 in the first embodiment. attached Figure 5 is a plan view of the acoustic sensor 41 . attached Figure 6 is a plan view of a state where the cover portion 44 is removed from the acoustic sensor 41 .

[0084] The acoustic sensor 41 is a capacitive element produced using MEMS technology. Such as Figure 4 As shown, in the acoustic sensor 41, the diaphragm 43 (vibrating electrode plate) is placed on the top surface of the silicon substrate 42 (semiconductor substrate) through a fixture 46, and the cover part 44 is fixed on it through a small air gap 50 (empty). top.

[0085] In the silicon substrate 42 made of single crystal silicon, a rear chamber 45 (hollow portion) penetrating from the front surface to the rear surface is opened. The inner peripheral surface of the ...

no. 2 example

[0138] Figure 12 is a plan view of the acoustic sensor 61 in Embodiment 2 of the present invention. Figure 13 It is a plan view of a state of the acoustic sensor 61 after the cover portion 44 is removed.

Embodiment 2

[0140] The acoustic sensor 61 in the second embodiment is a diaphragm 43 which is divided on it, and the area number is more than that of the acoustic sensor 41 in the first example. Even when the number of slits 47 is increased to increase the number of divided regions of the diaphragm 43 in this way (the shape and size of each diaphragm 43a, 43b, . The signal-to-noise ratio of the acoustic sensor 61 is feasible. In addition, as the number of divided regions of the diaphragm 43 increases, the effect of increasing the S / N ratio of the acoustic sensor 61 by reducing its noise increases accordingly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com