Method for preparing undaria pinnatifida sauce

A wakame and seasoning sauce technology is applied in the field of preparation of wakame seasoning sauce, and achieves the effects of strong operability, good taste and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

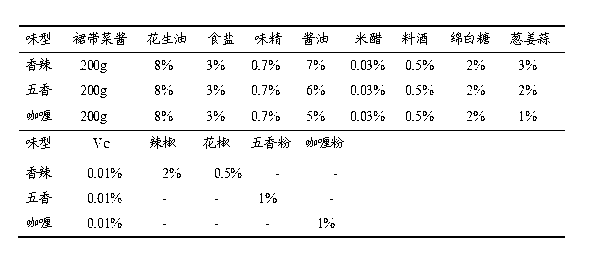

[0049] Embodiment 1, a kind of preparation method of wakame sauce, its steps are as follows:

[0050] (1) Pretreatment: choose dry wakame without mildew and rot, and wash the impurities with running water;

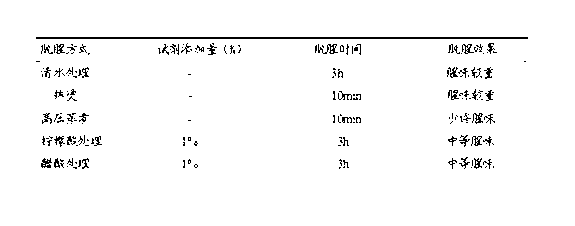

[0051] (2) Foaming and deodorization: put the washed dried wakame into appropriate amount of water for foaming, then add citric acid with a mass fraction of 0.8% to the foaming material, soak for 2 hours, take out and cut into shredded wakame stand-by;

[0052] (3) Color protection: put shredded wakame into a zinc chloride solution with a pH value of 4.8 and a mass concentration of 240 mg / L and boil for 9 minutes for color protection treatment;

[0053] (4) High-pressure cooking: Cook the shredded wakame after the color protection treatment in a sterilizing pot with a pressure of 0.07 MPa and a temperature of 121 °C for 18 minutes;

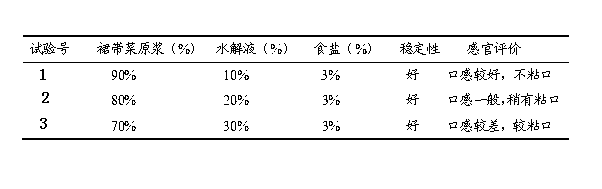

[0054] (5) Beating: Put the cooked shredded wakame and water together into a beater for beating to obtain wakame pulp; the water added for be...

Embodiment 2

[0057] Embodiment 2, a kind of preparation method of wakame sauce, its steps are as follows:

[0058] (1) Pretreatment: choose dry wakame without mildew and rot, and wash the impurities with running water;

[0059] (2) Foaming and deodorization: put the washed dried wakame into appropriate amount of water for foaming, then add citric acid with a mass fraction of 1.2% to the foaming material, soak for 4 hours, take out and cut into shredded wakame stand-by;

[0060] (3) Color protection: Put the shredded wakame into a zinc chloride solution with a pH value of 5.2 and a mass concentration of 260 mg / L and boil for 11 minutes to perform color protection treatment;

[0061] (4) High-pressure cooking: Cook the shredded wakame after the color protection treatment in a sterilizing pot with a pressure of 0.09 MPa and a temperature of 121 °C for 21 minutes;

[0062] (5) Beating: Put the boiled shredded wakame and water into a beater for beating to obtain wakame pulp; the water added f...

Embodiment 3

[0065] Embodiment 3, a kind of preparation method of wakame seasoning sauce, its steps are as follows:

[0066] (1) Pretreatment: choose dry wakame without mildew and rot, and wash the impurities with running water;

[0067] (2) Foaming and deodorization: Put the washed dried wakame into appropriate amount of water for foaming, then add citric acid with a mass fraction of 1.0% to the foaming material, soak for 3 hours, take out and cut into shredded wakame stand-by;

[0068] (3) Color protection: put shredded wakame into a zinc chloride solution with a pH value of 5.0 and a mass concentration of 250 mg / L and boil for 10 minutes for color protection treatment;

[0069] (4) High-pressure cooking: Cook the shredded wakame after the color protection treatment in a sterilizing pot with a pressure of 0.08 MPa and a temperature of 121 °C for 20 minutes;

[0070] (5) Beating: Put the boiled shredded wakame and water into a beater for beating to obtain wakame pulp; the water added fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com