Piston-type gas explosion fountain device

A fountain device and piston-type technology, which is applied in the field of piston-type gas explosion fountain devices, can solve the problems of thick atomization of water column tail gas, long time for spraying and replenishing water, complex structure, etc., and achieve the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

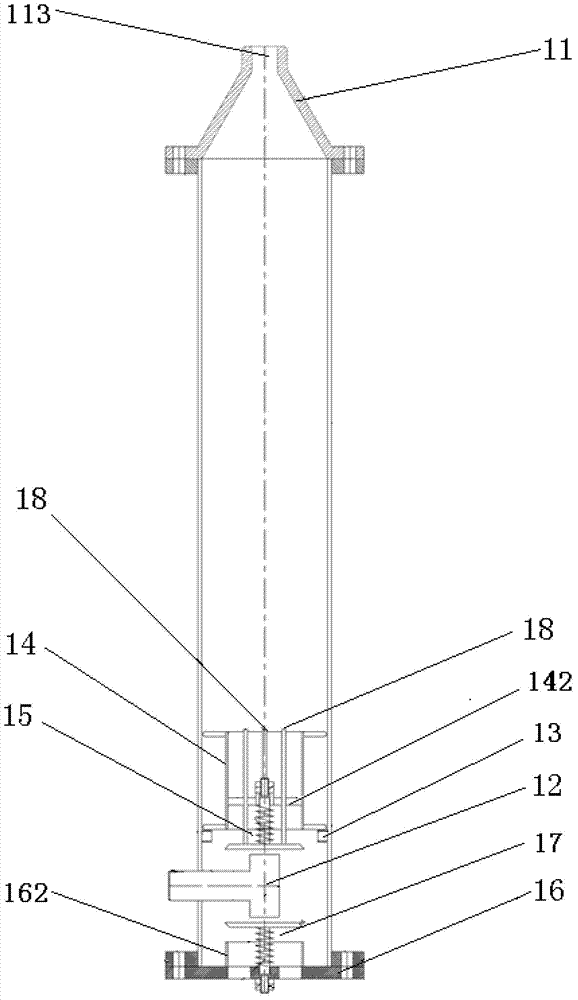

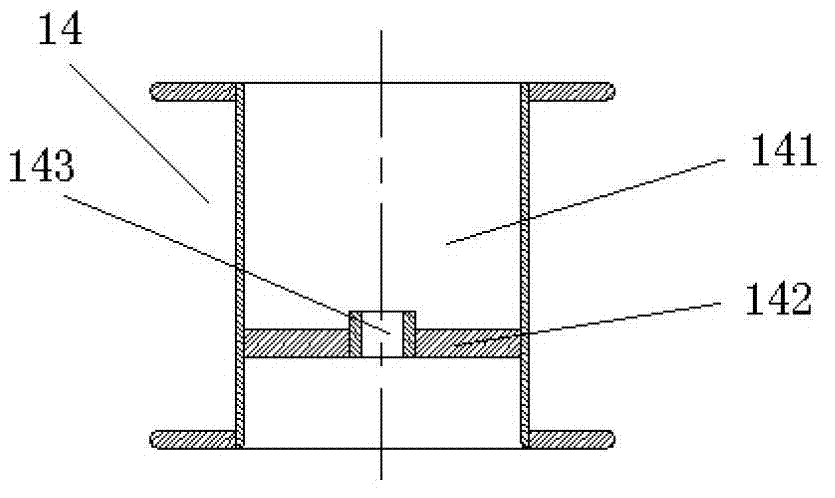

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

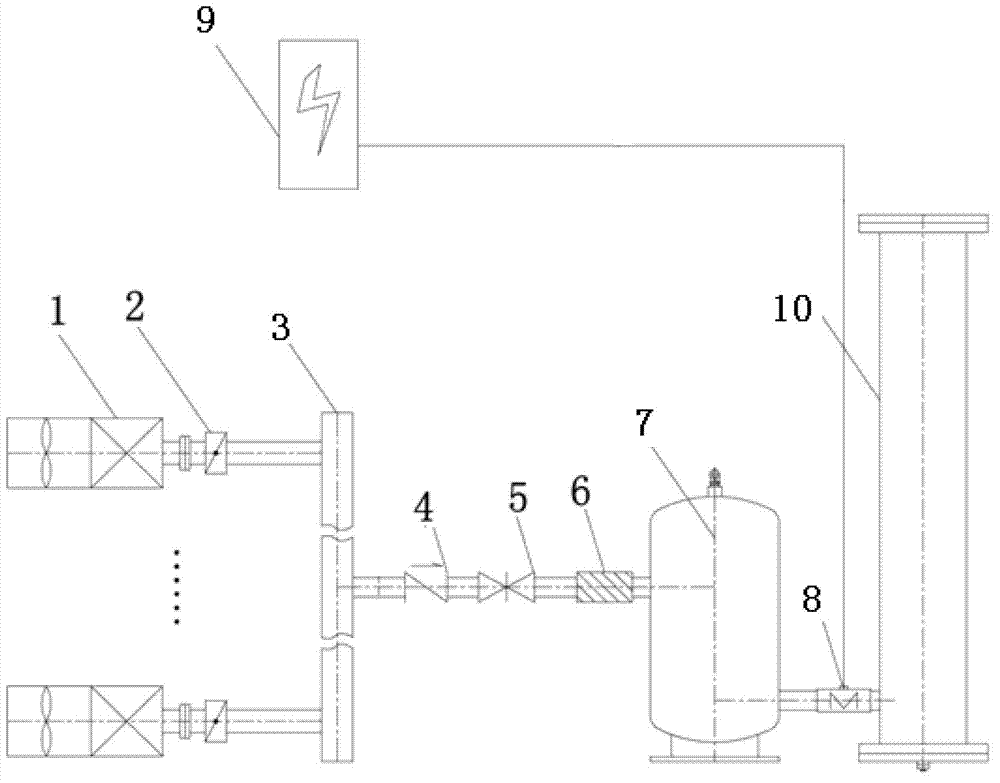

[0021] like figure 1 As shown, the present invention includes a gas source 1, the gas source 1 is connected to a gas pipeline 3 through a regulating valve 2 for adjusting the gas flow, and the output end of the gas pipeline 3 is sequentially connected to a one-way valve for preventing backflow 4. Another regulating valve 5 and an air filter 6 for filtering impurities are connected to an air storage tank 7, the outlet of the air storage tank 7 is connected to a solenoid valve 8, and the solenoid valve 8 is connected to an electric control cabinet through a cable 9. The other end of the solenoid valve 8 is connected to a water storage tank 10 .

[0022] Among the above-mentioned structural devices, various designs of the prior art can be adopted except for the water storage tank 10. For example, the air source 1 can adopt one or more air compressors co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com