Honeycomb composite board structure for container floor

A technology for honeycomb composite panels and containers, which is applied in synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of difficult observation of bamboo core defects, large dispersion of mechanical properties, and unsafety. Reduced material consumption, high mechanical properties, good fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with the drawings and embodiments, but the embodiments of the present invention are not limited thereto.

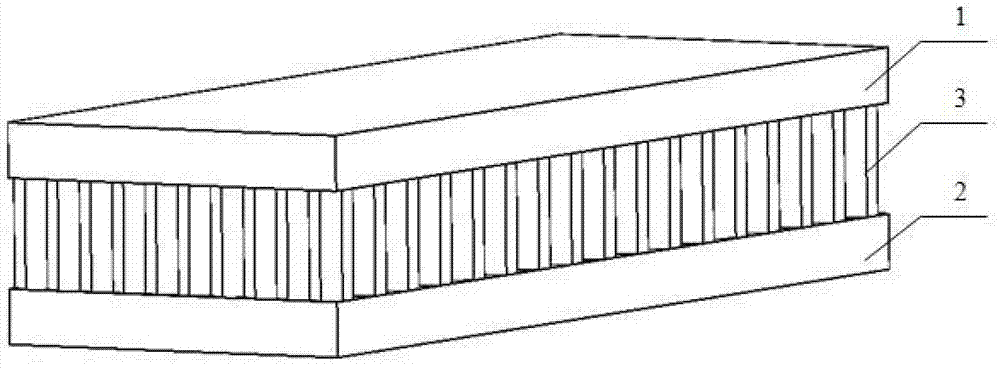

[0022] Such as figure 1 As shown, a container floor honeycomb composite panel structure includes a surface layer 1, a bottom layer 2 and a honeycomb core layer 3, wherein the surface layer 1 and the honeycomb core layer 3 are bonded between the bottom layer 2 and the honeycomb core layer 3; the surface layer 1 and the honeycomb core layer 3 are bonded; The bottom layer 2 is a glass steel plate; the honeycomb core layer 3 is made of aluminum alloy; the honeycomb core layer 3 is made of aluminum alloy, such as 3003 aluminum alloy, and other aluminum alloys with better mechanical properties than 3003 aluminum alloy can also be used.

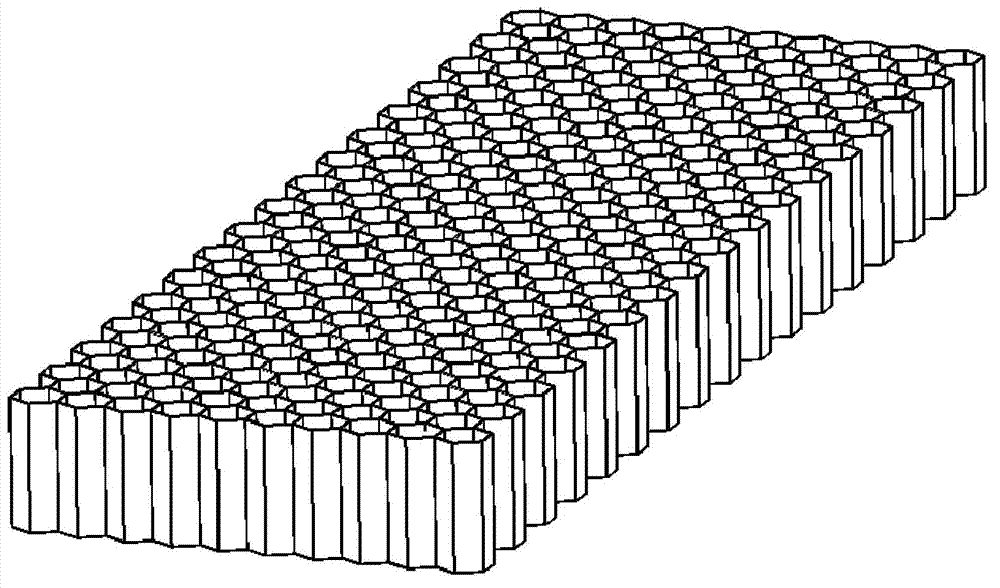

[0023] Such as figure 2 As shown, the honeycomb core layer 3 is a plate with a plurality of regular hexagonal thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com