Hollow sandwich structure and manufacture method thereof

A technology of hollow interlayer and interlayer structure, which is applied in the direction of aircraft parts, fuselage, transportation and packaging, etc. It can solve the problems that the structural center of gravity of the parts cannot be adjusted, and the stiffness distribution cannot be realized, so as to achieve increased stiffness, high yield, and surface good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

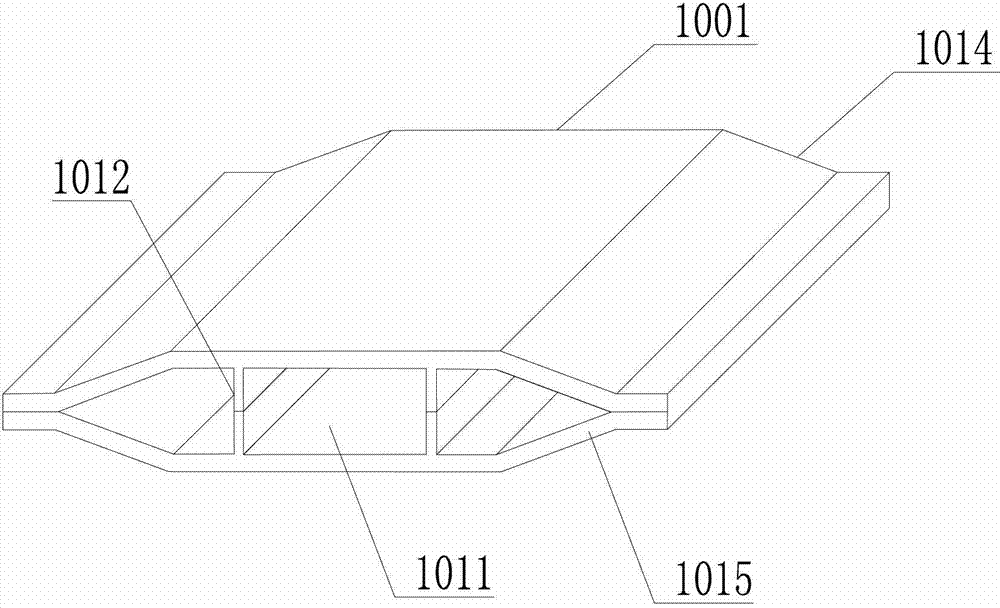

[0051] Such as Figure 1~3 As shown, a hollow sandwich structure, wherein the interior of the sandwich structure 1001 is a hollow cavity 1011 or consists of a hollow cavity 1011 and a solid structure (not shown), in order to enhance the structural strength of the sandwich structure, there are reinforcing ribs in the cavity 1011 1012, wherein the solid structure is used to change the structural center of gravity of the sandwich structure 1001 or to enhance the connection strength between the sandwich structure 1001 and other connecting parts, a solid structure is provided at the connection position of the sandwich structure 1001.

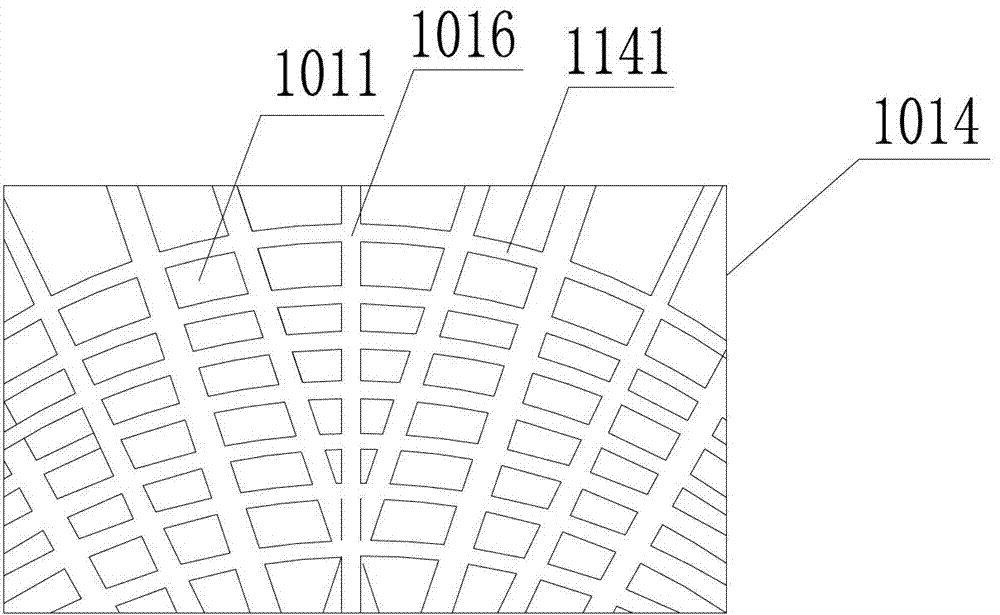

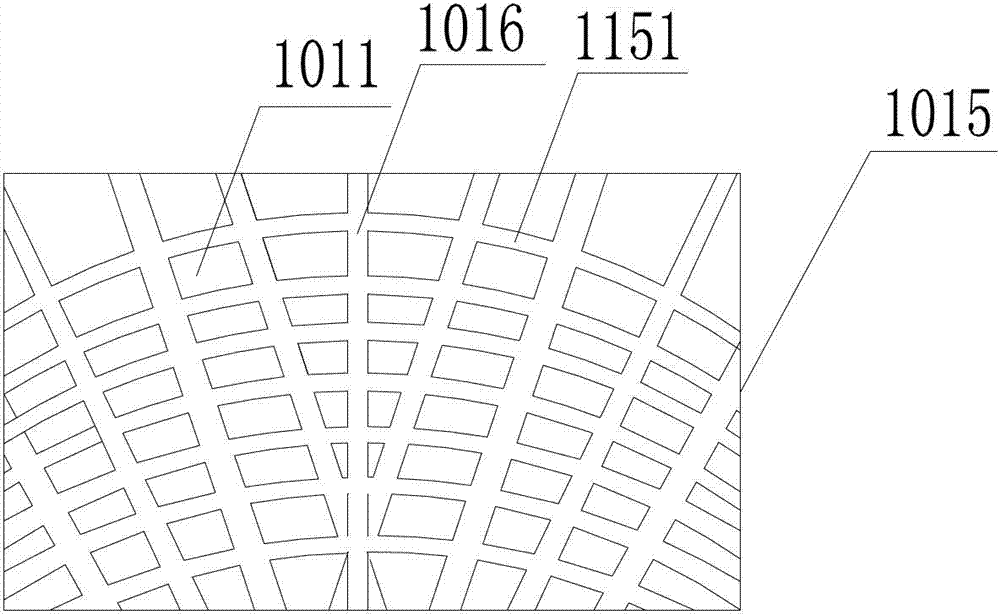

[0052] The sandwich structure 1001 includes an upper panel 1014 and a lower panel 1015, and there is a hollow cavity 1011 between the upper panel 1014 and the lower panel 1015, wherein the reinforcing rib 1012 includes an upper panel reinforcing rib 1141 arranged on the upper panel 1014, and an upper panel reinforcing rib 1141 arranged on the lower pa...

Embodiment approach 2

[0056] Such as Figure 4 , Figure 5 As shown, in this embodiment, except that the specific structure of the reinforcing rib 2012 is different from that of Embodiment 1, other structures are similar to that of Embodiment 1. In this embodiment, the reinforcing rib 2012 consists of a plurality of parallel upper The panel reinforcement rib 2141 and the lower panel reinforcement rib 2151 are formed. Preferably, the distance between each reinforcement rib 2012 composed of the upper panel reinforcement rib 2141 and the lower panel reinforcement rib 2151 parallel to each other is equal. The reinforcement rib 2012 of this structure is The production process is simple and convenient for processing and production.

Embodiment approach 3

[0058] Such as Figure 6 , Figure 7 As shown, in this embodiment, except that the specific structure of the reinforcing rib 3012 is different from that of Embodiment 1, other structures are similar to that of Embodiment 1. In this embodiment, the reinforcing rib 3012 is reinforced by multiple upper panels The network structure composed of the ribs 3141 and the lower panel reinforcement ribs 3151 has a network structure unit of triangle, trapezoid or rectangle and their combination, preferably the structure unit of the network structure composed of the reinforcement rib 3012 is a rectangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com