Continuous nitrocotton packaging production process

A production process and nitrocellulose technology, applied in packaging and other directions, can solve problems such as unfavorable large-scale production, prolonged heating or storage, and increased packaging processes, and achieve the effect of ensuring long-term safe operation, reducing volume, and avoiding burning and explosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings.

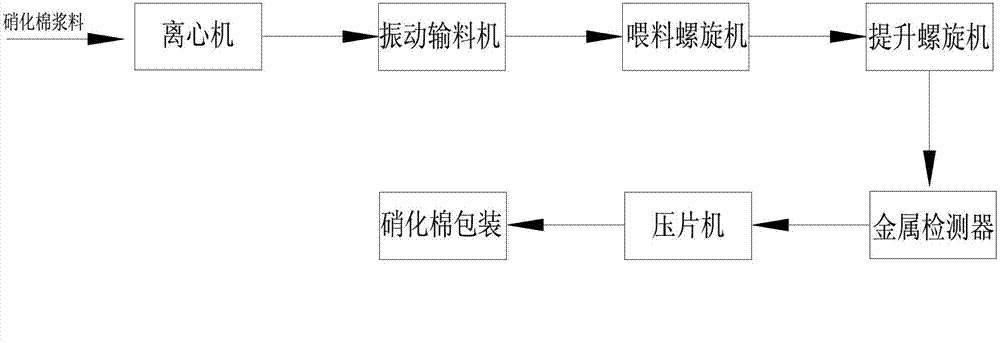

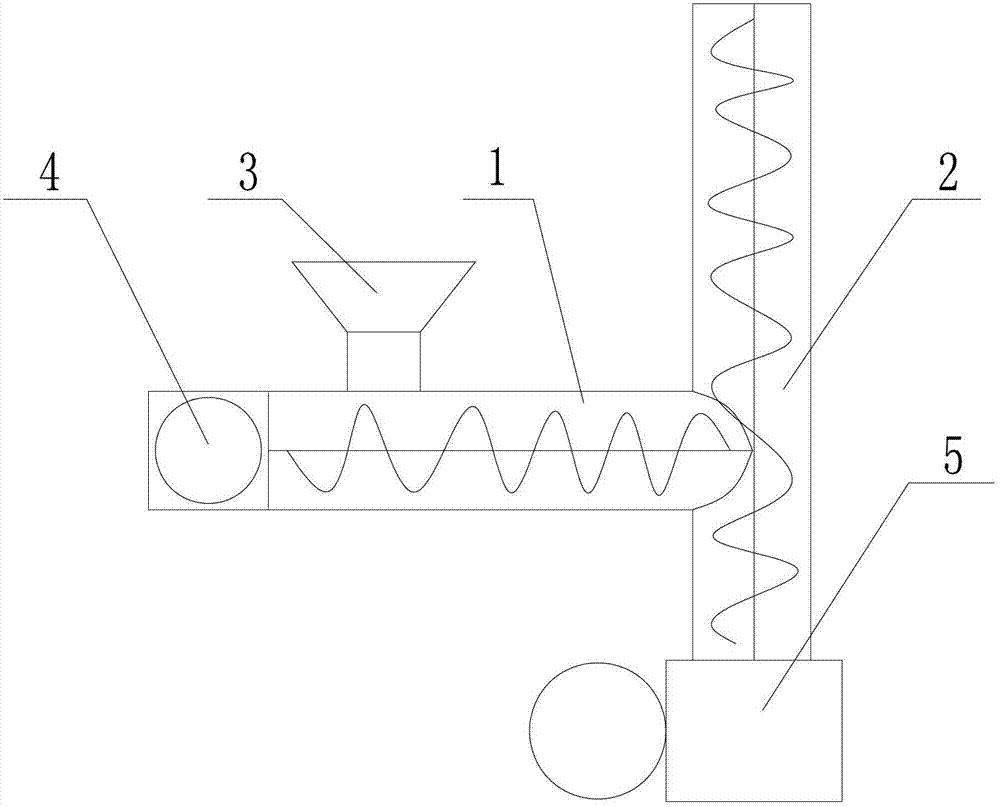

[0017] Such as figure 1 As shown, the present invention first dewaters the nitrocellulose slurry or replaces the water with alcohols, and then uses the conveying mechanism to transport the nitrocellulose to the metal detector. The metal detector is used to remove the metal contained in the nitrocellulose, and then the metal is removed The nitrocellulose is sent to the tablet press for tableting, and finally the compressed nitrocellulose is packaged. Dehydration is mainly achieved by a centrifuge. The nitrocellulose slurry is sent to the centrifuge, and the nitrocellulose slurry is continuously dewatered by centrifugation. Alcohols can also be used to replace the water, that is, add isopropanol, butanol and alcohol Replacement and flooding with alcohols. After dehydration or flooding, the nitrocellulose is transported to the next process through a conveying mechanism. This usually inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com