Rolling-wheel type scraping plate chains for coal cinder conveyor

A roller-type scraper and conveyor technology, which is applied in the field of roller-type scraper chain and cinder conveying, can solve the problems of large frictional resistance and wear, short mechanical life, high driving power, etc., and achieve small driving power and rigorous structure , Low maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

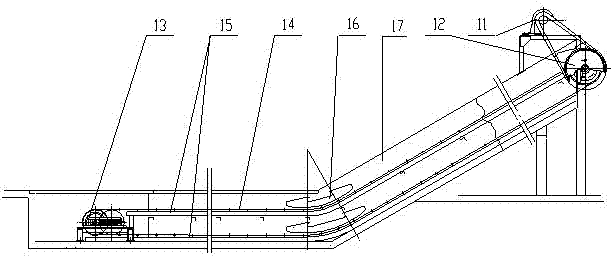

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

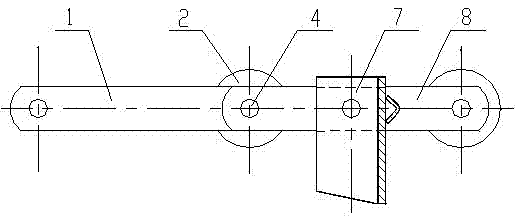

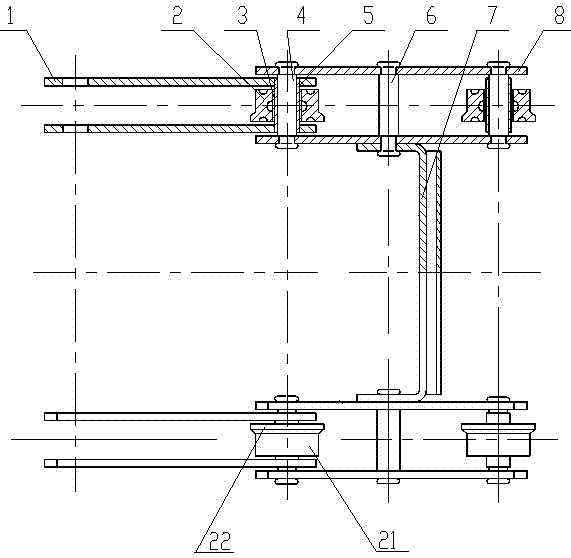

[0018] see figure 1 , figure 2 , a roller scraper chain for cinder conveyor, including roller 2, inner chain 1, outer chain 8, pin 4, scraper 7 and positioning shaft 6. Roller 2, inner chain piece 1, outer chain piece 8, and pin shaft 4 are based on the national standard "Conveyor Chains, Accessories and Sprockets" (GB / T8350-2008), and are carried out according to the characteristics of wet coal slag conveying in small and medium-sized industrial boiler rooms. According to the targeted design, the inner chain piece 1 and the outer chain piece 8 are installed in sequence on both sides of the roller 2, and the pin shaft 4 passes through the outer chain piece 8, the inner chain piece 1, the roller 2, the inner chain piece 1 and the outer chain piece in turn. 8. The chain is a double row chain. Every group of scraper chain 14 mainly is made up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com