Phase noise calibrating device based on photoelectric fusion technique

A phase noise and photoelectric fusion technology, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve the problems of high price, poor dynamic range, and low comparison measurement accuracy, and achieve the effect of simple structure and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

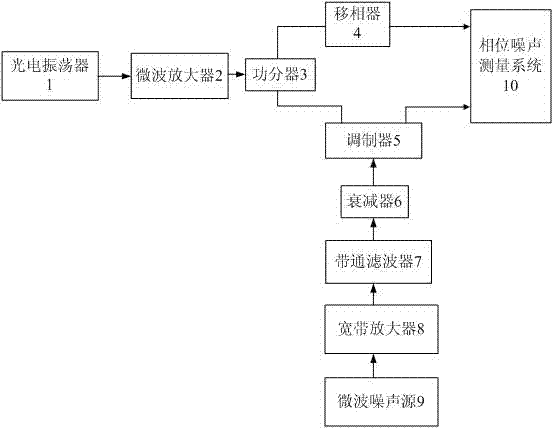

[0013] A phase noise calibration device based on photoelectric fusion technology, including: microwave amplifier 2, power divider 3, phase shifter 4, modulator 5, attenuator 6, phase noise measurement system 10, also includes: photoelectric oscillator 1, Microwave noise source 9, broadband amplifier 8, bandpass filter 7.

[0014] The output end of the photoelectric oscillator 1 is connected with the microwave cable at the input end of the microwave amplifier 2, the output end of the microwave amplifier 2 is connected with the microwave cable at the input end of the power divider 3, and the phase shifter end of the power divider 3 is connected with the input end of the phase shifter 4 by microwave cable connection, the modulation end of the power divider 3 is connected to the signal end of the modulator 5 with a microwave cable, the output end of the phase shifter 4 is connected to the microwave cable at the local oscillator end of the phase noise measurement system 10, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com