Preparation method of negative electrode plate of nickel-metal hydride battery

A technology of negative pole piece and nickel-metal hydride battery, which is applied in the direction of alkaline battery electrode, etc., can solve the problems of waste of negative electrode active material, serious self-discharge, battery explosion, etc., and achieves extended cycle life and storage life, high current charge and discharge. Effect enhancement, self-discharge and hydrogen evolution suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for manufacturing the negative pole piece of a nickel-hydrogen battery, the steps are:

[0031] In the first step, the negative electrode active material coating is a mixture of nano-metal hydrogen alloy (particle size of about 5-100nm), carbon nanotubes, and nanographite (particle size of about 5-35nm) with a mass ratio of 3:1:1. Active material mixture and PTFE emulsion (with a concentration of about 60wt%) accounting for 1.5% by weight of nano-metal hydrogen alloy, carbon nanotube, and nano-graphite mixture, and distilled water accounting for 15% by weight of nano-metal hydrogen alloy, carbon nanotube, and nano-graphite mixture Made into slurry;

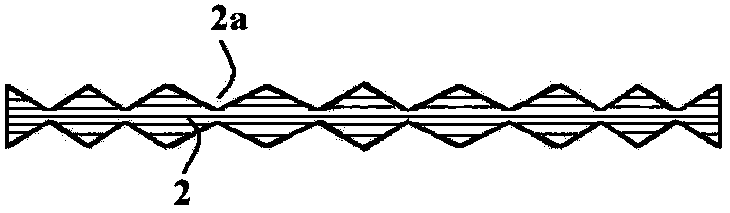

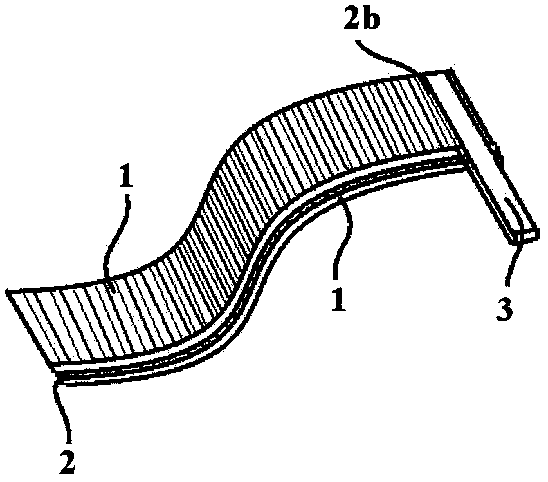

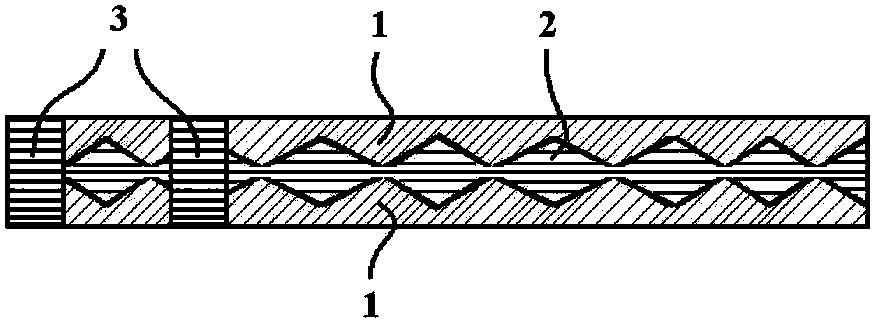

[0032] In the second step, the slurry produced in the first step is coated on the negative electrode current collector (2) through a sizing process, and then dried (temperature controlled at 65~85°C) and pressed by a roller to make the active material slurry The polar active material coating (1) is formed on the curren...

Embodiment 2

[0036] A method for manufacturing the negative pole piece of a nickel-hydrogen battery, the steps are:

[0037] In the first step, the negative electrode active material coating is a mixture of nano-metal hydrogen alloy (particle size about 5-100nm), carbon nanotubes, and nano-graphite (particle size about 5-35nm) with a mass ratio of 3:0.6:0.6. The active material mixture and PTFE which accounts for 1.8% of the mass ratio of nano metal hydrogen alloy, carbon nanotube, and nano graphite mixture, and distilled water which accounts for 20% of the mass ratio of nano metal hydrogen alloy, carbon nanotube, and nano graphite mixture to form a slurry;

[0038] In the second step, the slurry produced in the first step is coated on the negative electrode current collector (2) through a sizing process, and then dried (temperature control 65~85℃) and pressed by a roller to make the active material slurry Form a very active material coating (1) on the current collector, after cutting and other...

Embodiment 3

[0042] A method for manufacturing the negative pole piece of a nickel-hydrogen battery, the steps are:

[0043] In the first step, the negative electrode active material coating is a mixture of nano-metal hydrogen alloy (particle size about 5-100nm), carbon nanotubes, and nanographite (particle size about 5-35nm) with a mass ratio of 3:0.75:0.75. The active material mixture, PTFE with a mass ratio of 2% of the nano-metal hydrogen alloy, carbon nanotube, and nano-graphite mixture, and distilled water with a mass ratio of 25% of the nano-metal hydrogen alloy, carbon nanotube, and nano-graphite mixture are made into a slurry;

[0044] In the second step, the slurry produced in the first step is coated on the negative electrode current collector (2) through a sizing process, and then dried (temperature control 65~85℃) and pressed by a roller to make the active material slurry Form a very active material coating (1) on the current collector, after cutting and other processes, and then u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com