Manufacturing method of nickel-cadmium battery cadmium negative electrode

A nickel-cadmium battery and a manufacturing method technology, which are applied to battery electrodes, alkaline battery electrodes, electrode carriers/current collectors, etc., can solve the problems of waste of negative electrode active materials, serious self-discharge, mismatched structure of positive electrode and pole pieces, etc. The effect of prolonging cycle life and storage life, suppressing self-discharge and memory effect phenomenon, and improving high-current charge and discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

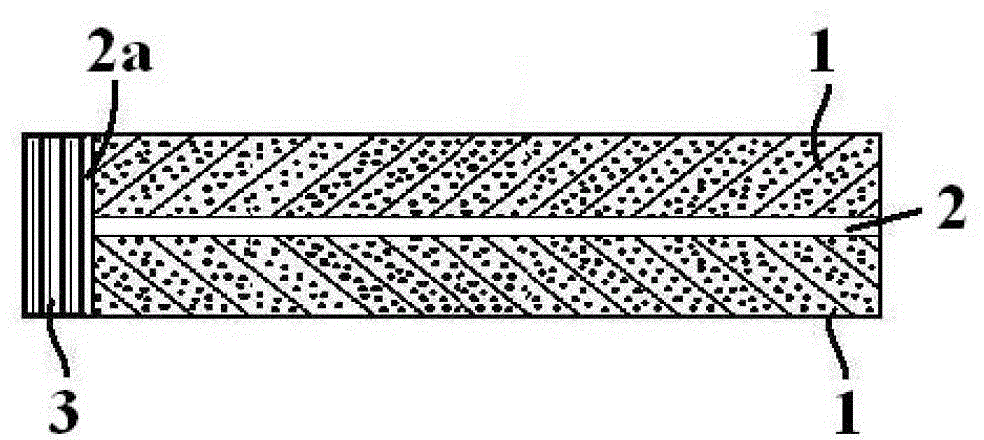

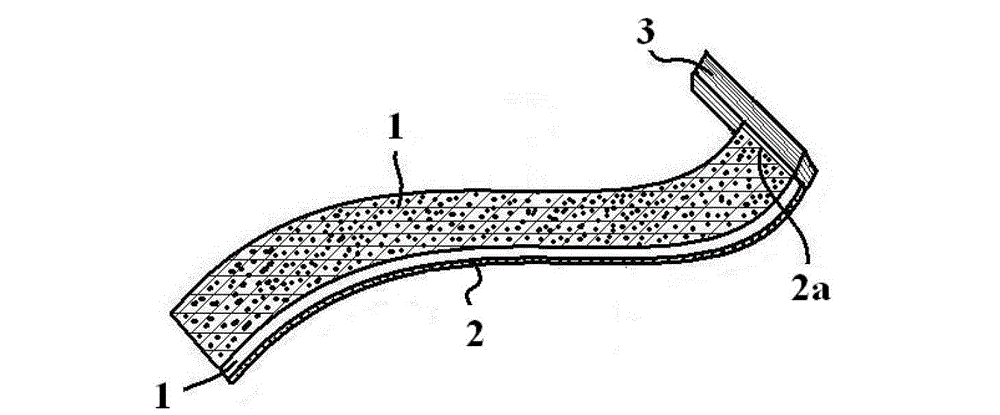

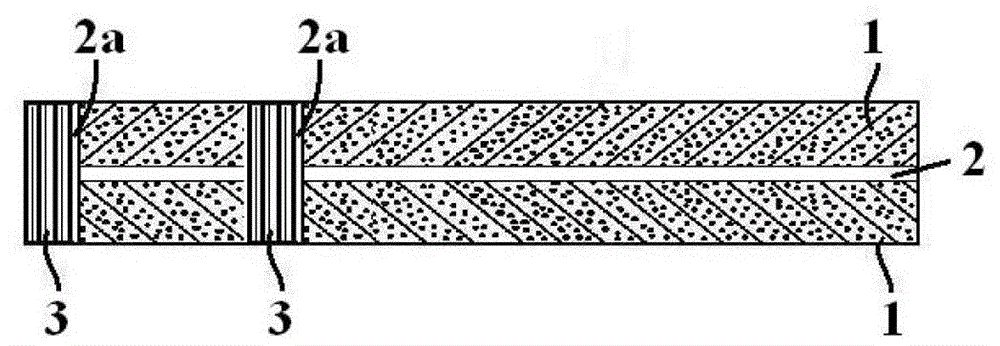

[0035] In the first step, the negative electrode active material coating 1 is an active material mixture composed of ultrafine cadmium oxide (CdO), nano-graphite and carbon nanotubes mixed in a mass ratio of 7.5:0.5:2;

[0036] And a mixed binder of polytetrafluoroethylene (PTFE) and polyvinylidene fluoride (PVDF) mixed in an equal mass ratio of 2% of the mass of the active material mixture, as a negative electrode mixed binder (polytetrafluoroethylene is polytetrafluoroethylene Polytetrafluoroethylene emulsion with a solid content of 60% vinyl fluoride, polyvinylidene fluoride is a polyvinylidene fluoride emulsion with a solid content of 60% polyvinylidene fluoride);

[0037] And sodium carboxymethylcellulose (CMC) accounting for 1% by mass of the active substance mixture as a negative electrode thickener;

[0038] And the distilled water that accounts for the mass ratio of active substance mixture 25%;

[0039] mixing the active material mixture, negative electrode mixing b...

Embodiment 2

[0043]In the first step, the negative electrode active material coating 1 is an active material mixture composed of superfine cadmium oxide (CdO), nano-graphite and carbon nanotubes mixed in a mass ratio of 7.5:0.6:3 in sequence;

[0044] And a mixed binder of polytetrafluoroethylene (PTFE) and polyvinylidene fluoride (PVDF) mixed in an equal mass ratio of 3% of the mass of the active material mixture, as a negative electrode mixed binder (polytetrafluoroethylene is polytetrafluoroethylene Polytetrafluoroethylene emulsion with a solid content of 60% vinyl fluoride, polyvinylidene fluoride is a polyvinylidene fluoride emulsion with a solid content of 60% polyvinylidene fluoride);

[0045] And sodium carboxymethylcellulose (CMC) accounting for 1.5% by mass of the active substance mixture as a negative electrode thickener;

[0046] And the distilled water that accounts for 30% of the mass ratio of active substance mixture;

[0047] mixing the active material mixture, negative el...

Embodiment 3

[0051] In the first step, the negative electrode active material coating 1 is an active material mixture composed of ultrafine cadmium oxide (CdO), nano-graphite and carbon nanotubes mixed in a mass ratio of 7.5:0.7:4 in sequence;

[0052] And a mixed binder of polytetrafluoroethylene (PTFE) and polyvinylidene fluoride (PVDF) mixed in an equal mass ratio of 3.5% of the mass of the active material mixture, as a negative electrode mixed binder (polytetrafluoroethylene is polytetrafluoroethylene Polytetrafluoroethylene emulsion with a solid content of 60% vinyl fluoride, polyvinylidene fluoride is a polyvinylidene fluoride emulsion with a solid content of 60% polyvinylidene fluoride);

[0053] And sodium carboxymethylcellulose (CMC) accounting for 1.8% by mass of the active substance mixture as a negative electrode thickener;

[0054] And the distilled water that accounts for 40% of the mass ratio of active substance mixture;

[0055] mixing the active material mixture, negative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com