Low-cost manufacturing method for high-intensity quenched and tempered steel plate

A quenched and tempered steel plate and a manufacturing method technology, applied in the metallurgical field, can solve the problems of high production cost and no flexible manufacturing process, and achieve the effects of reducing alloy cost, saving precious alloying elements, and improving hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The chemical composition of the high-strength quenched and tempered steel plate with a thickness of 30mm is selected, and the weight percentage is: C: 0.16%, Si: 0.25%, Mn: 1.50%, P: 0.010%, S: 0.004%, Cr: 0.45%, Al: 0.025 %, B: 0.0015%, Ti: 0.015%, and the rest are Fe and unavoidable impurities.

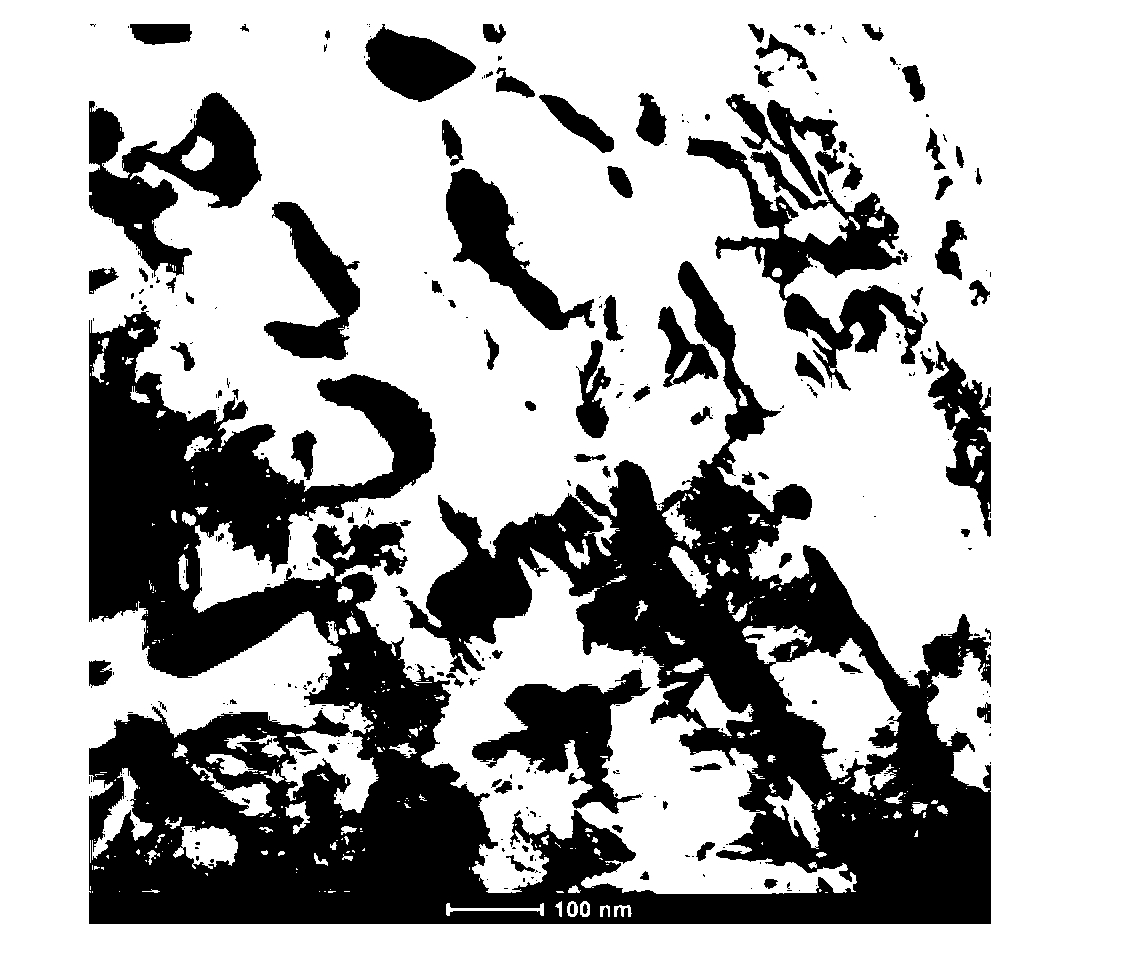

[0029] Heat the qualified billet to 1180°C, keep it warm for 200min, and control rolling. Air cool to room temperature. The quenching heating temperature is 810°C, the holding time is 1.6×30+10=58min, and the quenching machine is water-quenched to room temperature after being released from the furnace. Then tempering treatment, tempering temperature 690 ° C, tempering time 2.0 × 30 + 5 = 65min, to obtain 60kg grade high-strength steel (Q460C), the structure is as follows figure 1 shown. Its yield strength is 559MPa, tensile strength is 661MPa, elongation after fracture is 21%, longitudinal impact energy at 0°C is 258J / 247J / 249J, and longitudinal impact energy at -40°C is 2...

Embodiment 2

[0031] Its composition is the same as embodiment 1, and heating, rolling, steel plate thickness, quenching process are the same as embodiment 1.

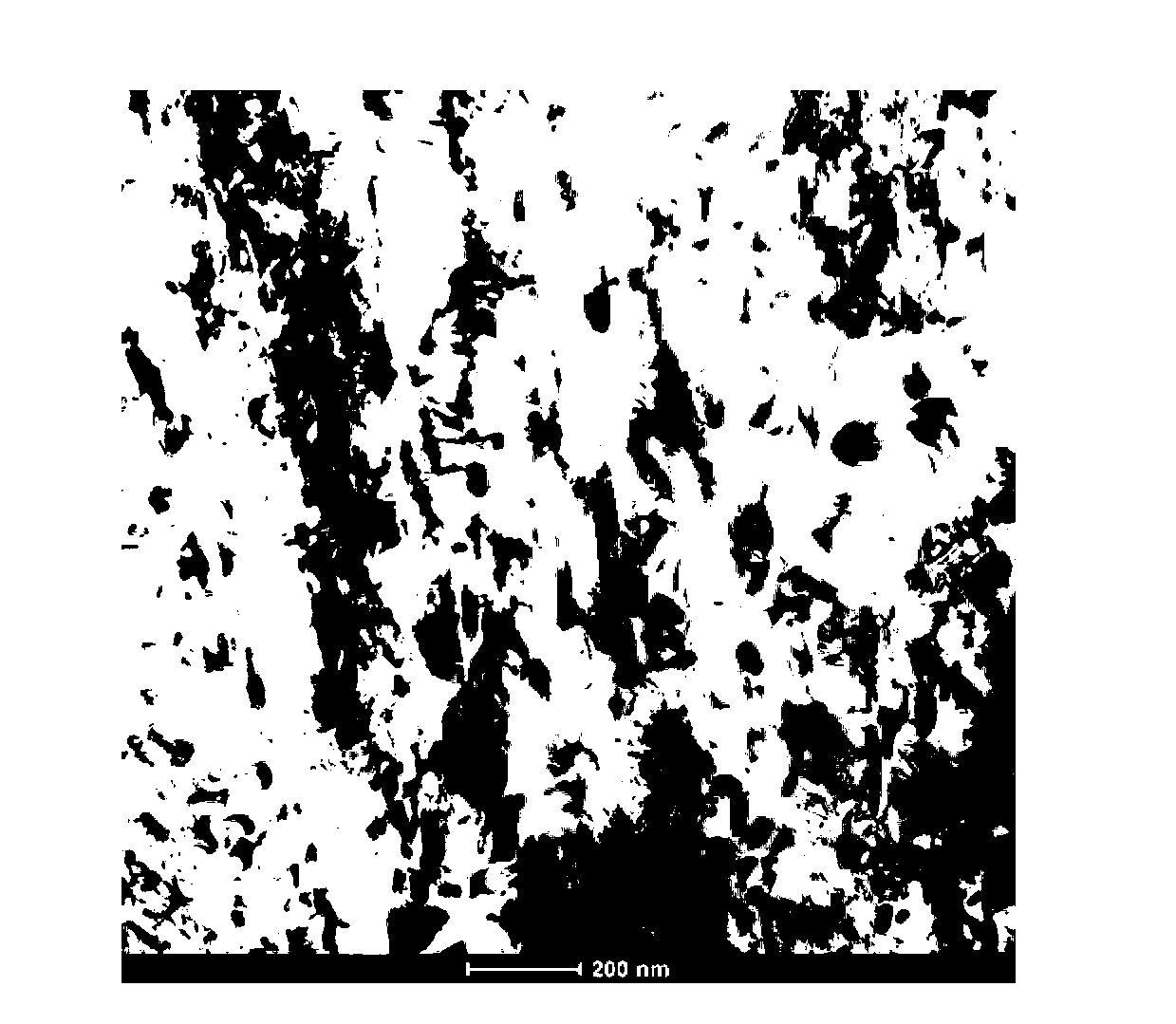

[0032] The tempering temperature is 650°C, the tempering time is 2.0×30+5=65min, and the 70kg grade high-strength steel (Q550D) is obtained. The structure is as follows: figure 2 shown. Its yield strength is 611MPa, tensile strength is 719MPa, elongation after fracture is 19.5%, longitudinal impact energy at -20°C is 184J / 175J / 208J, and longitudinal impact energy at -40°C is 174J / 147J / 169J.

Embodiment 3

[0034] Its composition is the same as embodiment 1, and heating, rolling, steel plate thickness, quenching process are the same as embodiment 1.

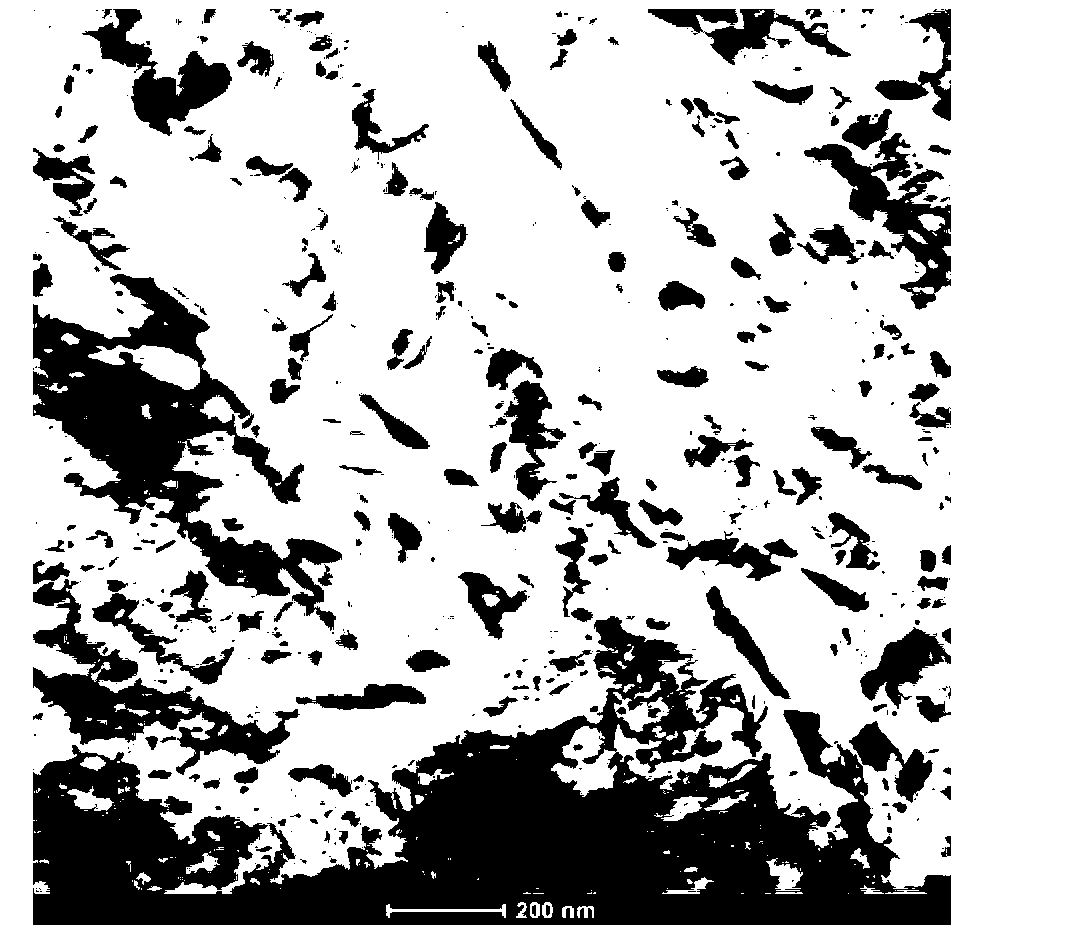

[0035] The tempering temperature is 610°C, the tempering time is 2.2×30+5=71min, and the 75kg grade high-strength steel (Q620D) is obtained. The structure is as follows image 3 shown. Its yield strength is 676MPa, tensile strength is 772MPa, elongation after fracture is 18%, longitudinal impact energy at -20°C is 157J / 165J / 136J, and longitudinal impact energy at -40°C is 137J / 129J / 113J.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com