Two-shaft fiber interactive equal-feed composite spinning device, process and application

A composite spinning and shafting technology, applied in the directions of spinning machines, yarns, textiles, and papermaking, etc., can solve the problem that the elastic yarn cannot be intermittently transposed and moved left and right, and the elastic yarn cannot be intermittently transposed and moved. It is impossible to carry out the problems of intermittent transposition and movement of the filament left and right, so as to achieve the effect of convenient production adjustment, convenient production, convenient installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

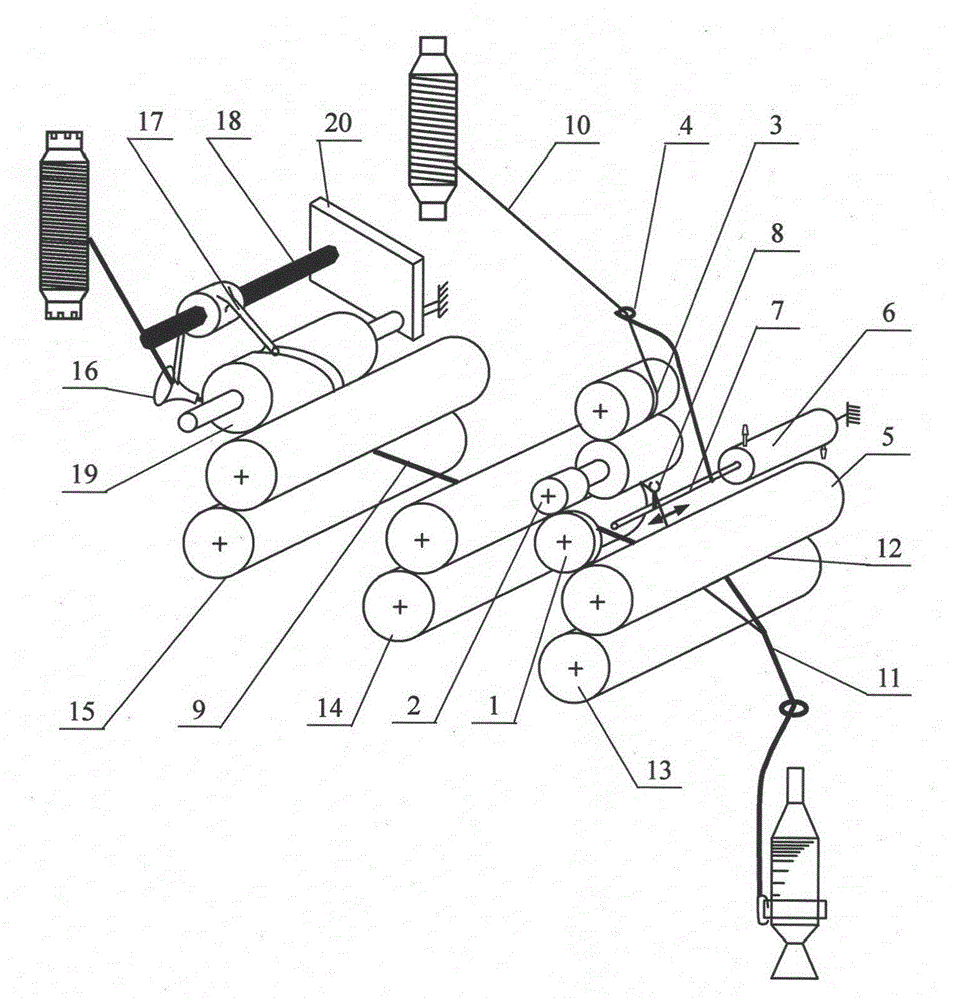

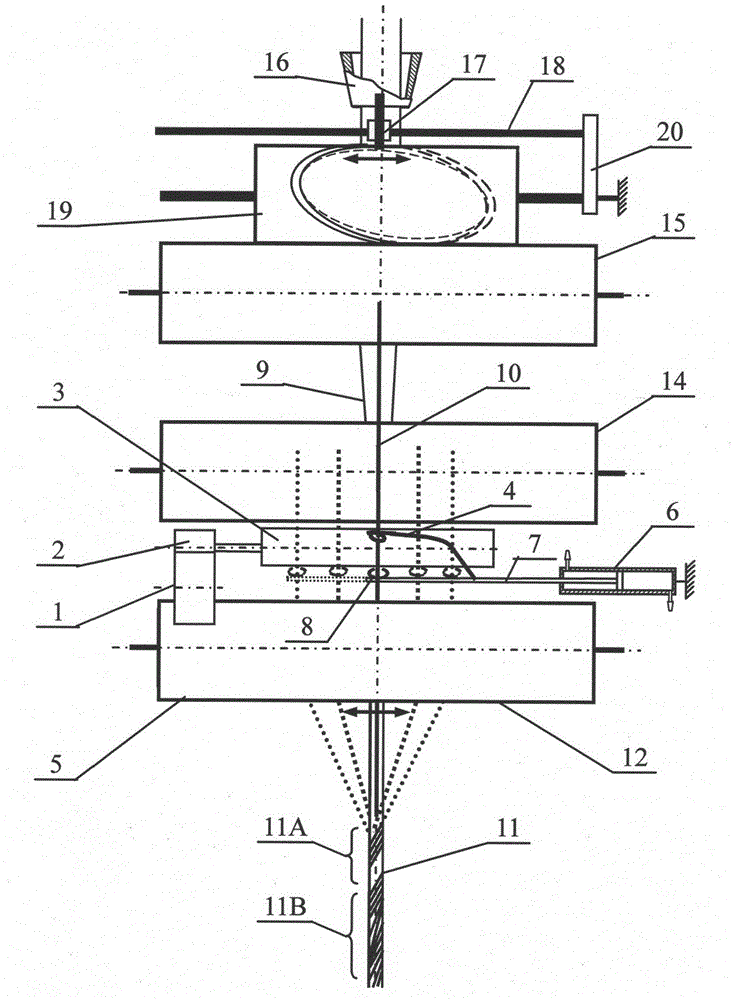

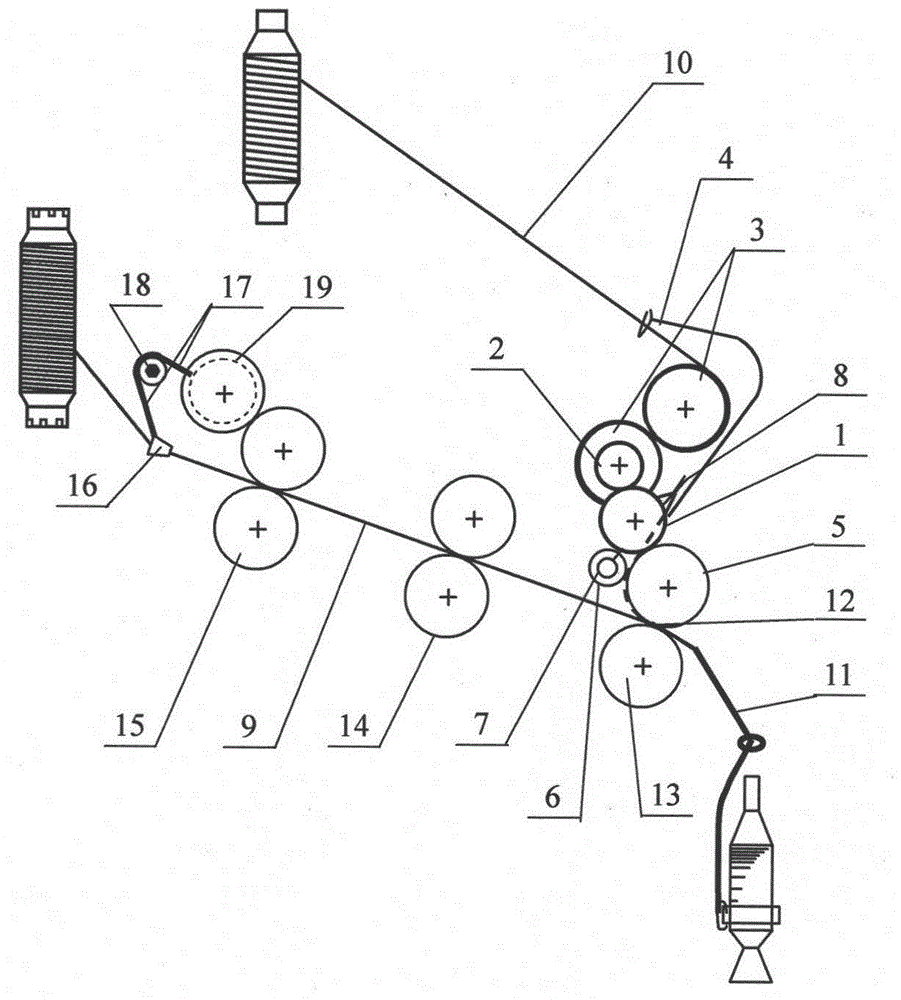

[0037] Using the dual-axis fiber interactive equal-feed composite spinning device of the present invention, after the cotton yarn is equal-fed according to the above method, it interacts with kapok fiber strands to form a two-component equal-feed composite spinning For core-spun composite yarn, the specific process parameters are shown in the table below, wherein the cotton yarn after the holding roller pair 3 is output without tension, and is basically fed into the front roller nip 12 in equal amounts. The spun two-component equal-feed wrapping core-spun composite yarn, because the cotton yarn is periodically transposed and the kapok fiber strands are symmetrically moved left and right, so the appearance of the yarn has an obvious symmetrical and intermittent pattern. The variable wrapping core wrapping effect, see figure 2 11A segment yarn. The composite spinning with wrapping and core-spun periodically alternates has a high yield of yarn, which means that there is very li...

Embodiment 2

[0039] Using the dual-axis fiber interactive iso-feed composite spinning device of the present invention, after the viscose filament is fed by the above-mentioned method, the composite spinning with cotton fiber strands is interactively fed to form a two-component, etc.-feed composite spinning device. The specific process parameters of the wrapping core-spun composite yarn are shown in the table below, wherein the viscose filament after the gripping roller pair 3 is output without tension, and is basically fed into the front roller nip 12 in equal amounts. The spun two-component equal-feed wrapping core-spun composite yarn, because the viscose filaments are randomly transposed and the cotton fiber strands move left and right, so the appearance of the yarn has obvious differences. Asymmetrical, intermittent variable wrapping effect, see figure 2 11A segment yarn. Since the strand shifting mechanism is installed at the rear of the middle roller, the change period of the wrappi...

Embodiment 3

[0041] Using the dual-axis fiber interactive iso-feed composite spinning device of the present invention, after the polyester filament is fed by the above-mentioned method, the composite spinning is carried out with the wool fiber strands to form a two-component iso-feed type The wrapping core-spun composite yarn, the specific process parameters are shown in the table below, wherein the polyester filament after the holding roller pair 3 is output without tension, and is basically fed into the front roller nip 12 in equal amounts. The spun two-component equal-feed wrapping core-spun composite yarn, because the polyester filaments move periodically and the wool fiber strands move left and right, the yarn has obvious abnormalities in appearance. Symmetrical, graduated variable wrap core wrapping effect, see figure 2 The 11B segment yarn. The composite spinning with periodic and alternating wrapping and wrapping has a high rate of yarn formation, which means that there is very l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com