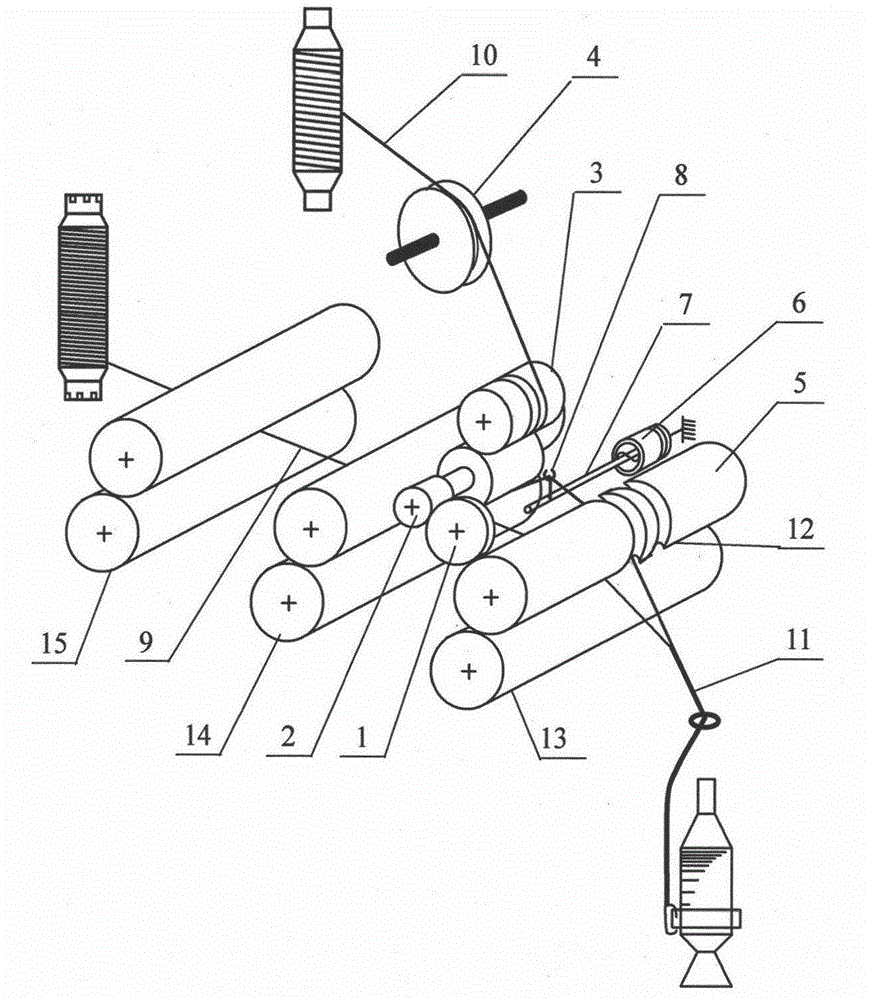

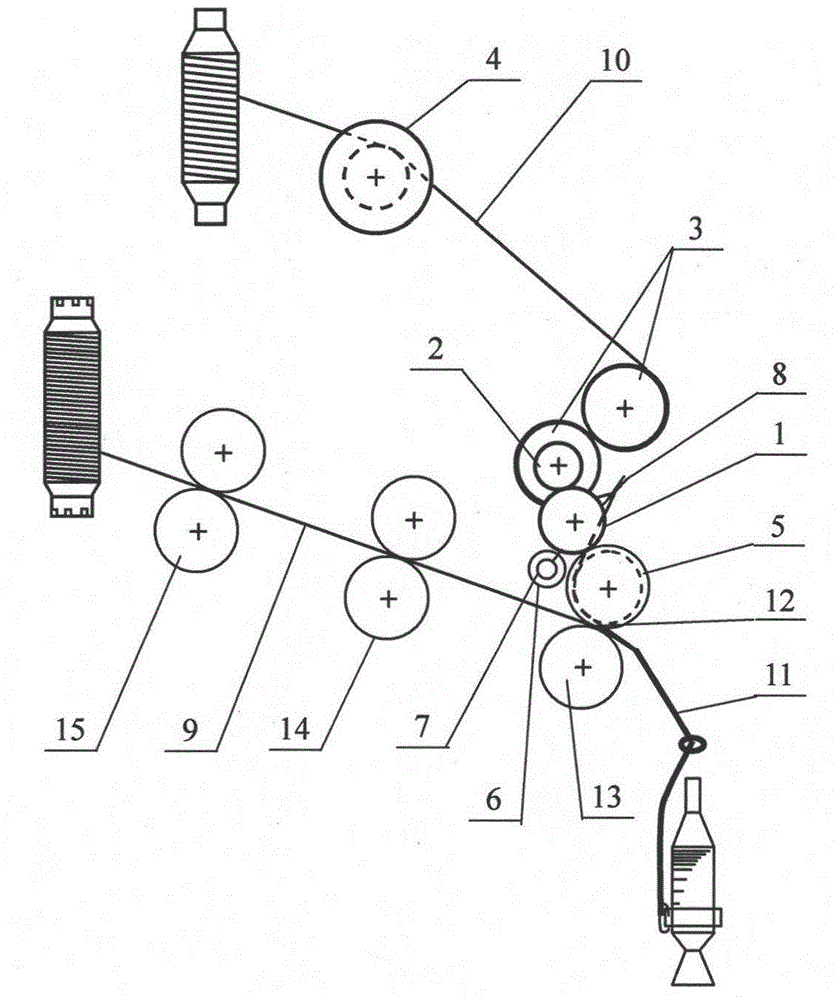

Singe-side two-groove intermittent overfeeding composite spinning device and process

A compound spinning and intermittent technology, applied in the direction of yarn, textiles and paper making, etc., can solve the problems of high tension of filament yarn and inability to realize overfeeding, etc., achieve effective contact transmission, realize effect and quality, and facilitate adjustment and change Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

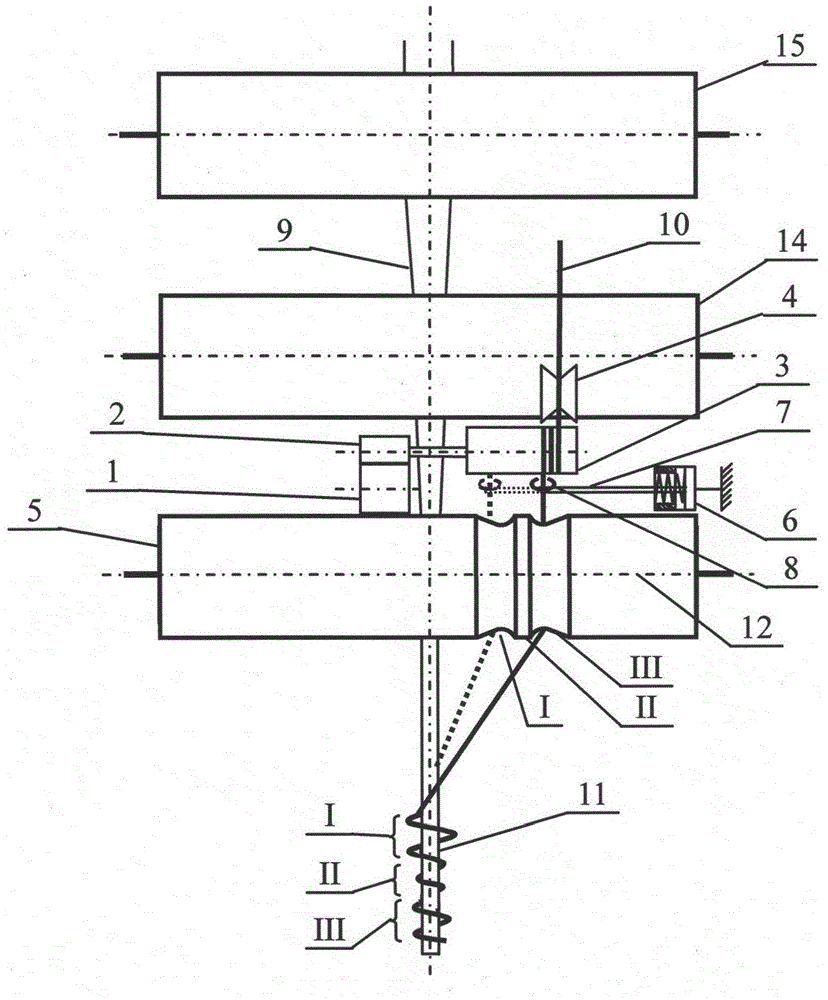

[0035] Using the one-side two-groove intermittent overfeeding composite spinning method of the present invention, after the PTT filament bundle is overfed according to the above method, the composite spinning of intermittent overfeeding with kapok fiber strands is carried out to form a two-component intermittent For overfeed wrapping composite yarn, the specific process parameters are shown in the table below. The spun two-component intermittent overfeed wrapped composite yarn has an obvious appearance of variable wrapping effect, such as image 3 The I, II, and III parts of the intermittent wrapping composite yarn 11 are the effects of feeding and wrapping in the I, II, and III areas. The yarn-making rate is very high, which means that there is little fiber loss such as flying flowers, crumbs, and end breaks; the end-break rate is extremely low due to the continuity and protection of filaments at the time of thousand spindles, which means that the spinnability of yarn process...

Embodiment 2

[0037] Using the single-side two-groove intermittent overfeed composite spinning method of the present invention, after the cotton yarn is overfed according to the above method, it is combined with cotton fiber strands to perform intermittent overfeed composite spinning to form a two-component intermittent overfeed composite spinning method. Wrapped composite yarn, the specific process parameters are shown in the table below. The spun two-component intermittent overfeed wrapped composite yarn has an obvious appearance of variable wrapping effect, such as image 3 The I, II, and III parts of the intermittent wrapping composite yarn 11 are the effects of feeding and wrapping in the I, II, and III areas. The yarn-making rate is very high, which means that there is little fiber loss such as flying flowers, crumbs, and end breaks; the end-break rate is extremely low due to the continuity and protection of filaments at the time of thousand spindles, which means that the spinnability...

Embodiment 3

[0039] Using the one-side two-groove intermittent overfeed composite spinning method of the present invention, after the nylon filament bundle is overfed according to the above method, it is compositely spun intermittently overfeed with short wool fiber strands to form a two-component For intermittent overfeed wrapping composite yarn, the specific process parameters are shown in the table below. The spun two-component intermittent overfeed wrapped composite yarn has an obvious appearance of variable wrapping effect, such as image 3 The I, II, and III parts of the intermittent wrapping composite yarn 11 are the effects of feeding and wrapping in the I, II, and III areas. The yarn-making rate is very high, which means that there is little fiber loss such as flying flowers, crumbs, and end breaks; the end-break rate is extremely low due to the continuity and protection of filaments at the time of thousand spindles, which means that the spinnability of yarn processing is good and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com