Manufacturing method of cast-in-place LOFT floor slab

A production method and floor board technology, which is applied to floor boards, building material processing, building components, etc., can solve problems such as non-fireproof, non-moisture-proof, and poor sound insulation, and achieve the effects of low overall cost, light bulk density, and reduced dead load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

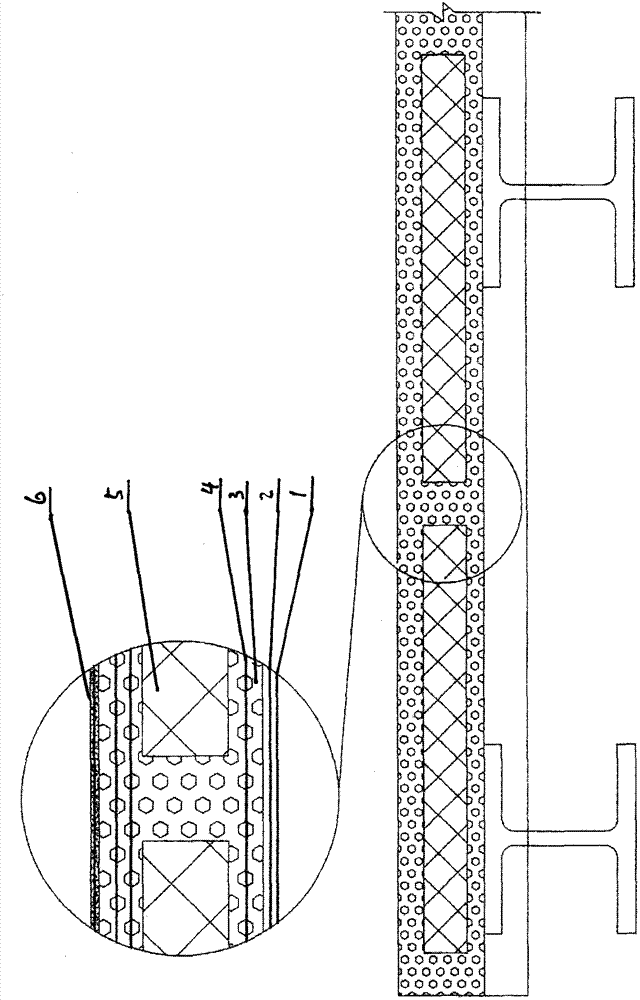

[0008] The manufacturing method of the cast-in-place LOFT floor slab is to carry out secondary design and construction according to the pattern of the construction site after the main project of the civil engineering has been completed. The I-beam and channel steel structures must meet the force requirements of the balance load. Weld the galvanized steel mesh 1 on the above-mentioned I-beam and channel steel, and then bind and weld the galvanized steel mesh 2 and the steel mesh 1. The overlapping part of the steel mesh 1 and its surroundings should be welded with 3# flat steel (welding point The spacing is not greater than 30), and then poured with DFB light aggregate 3, the process flow is: wipe the first layer of DFB aggregate 3 (20mm) - spread a layer of glass mesh cloth 4 - wipe the second layer of DFB aggregate Material 3 (20mm)——Lay the second layer of glass silk mesh cloth 4 layers—Lay polystyrene board 5, the density of polystyrene board 5 is 20kg, the size is 1000×600×...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com