Main steam valve of steam turbine

A steam turbine and valve technology, applied in the field of steam turbines, can solve the problems of high-quality steam leakage, increased design and processing difficulty, and reduced manufacturing efficiency, so as to avoid upgrading and expansion of specifications, reduce structural strength requirements, and improve manufacturing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

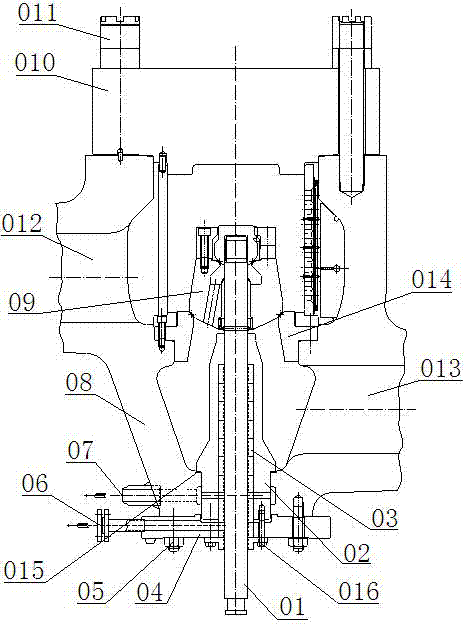

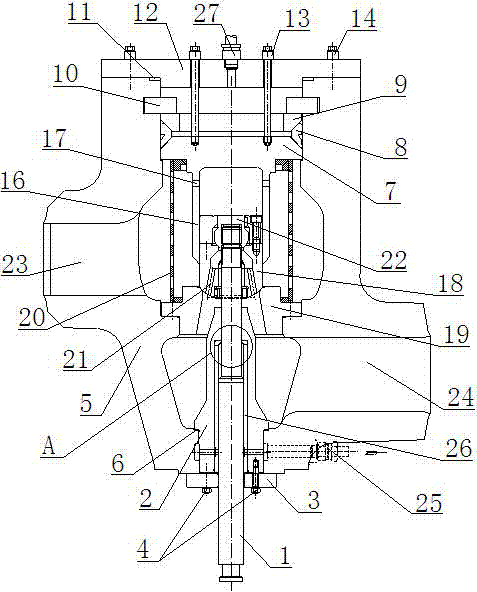

[0030] see figure 2 and image 3 : The present invention comprises a valve body 5, a valve cover and a valve stem 1.

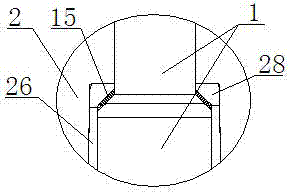

[0031]Wherein, the valve body 5 is an inner hollow structure, that is, the valve body 5 has an inner surface and an outer surface. The valve body 5 is provided with an upstream steam passage 23, a downstream steam passage 24, a valve stem assembly hole and a valve cover assembly hole, the upstream steam passage 23 and the downstream steam passage 24 are radially staggered, and the upstream steam passage 23 and the downstream steam passage 24 A valve seat 19 is fixed on the inner surface of the valve body 5 therebetween. The bonnet mounting hole is located on the top of the valve body 5 . The valve stem assembly hole is located at the bottom of the valve body 5, and the inner end of the valve stem assembly hole is provided with a limit step 6, and a sleeve 2 is inserted into the valve stem assembly hole, and the outer circumference of the sleeve 2 is limite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com