Hydrographic survey device for small water area

A hydrographic survey and water area technology, applied in surveying devices, open-air water source surveys, surveying and mapping, and navigation, etc., can solve problems such as unstable equipment data collection efficiency and complex mechanical structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

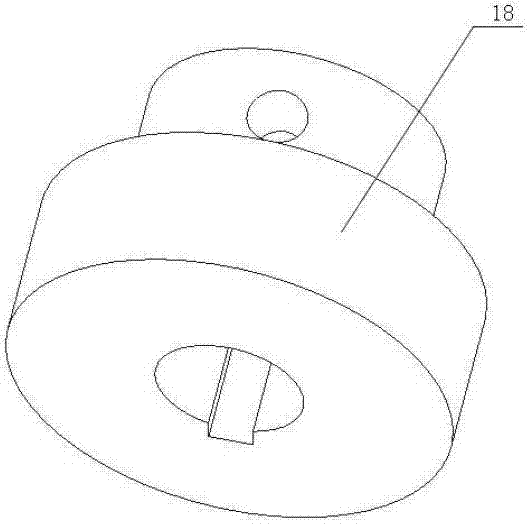

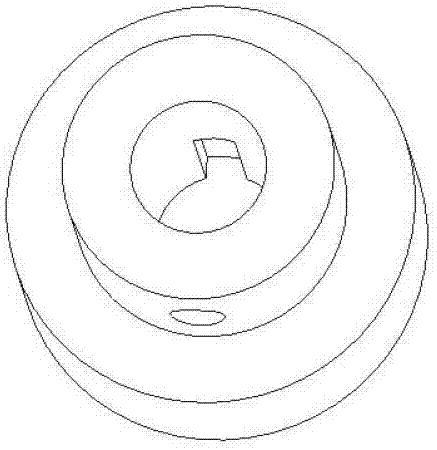

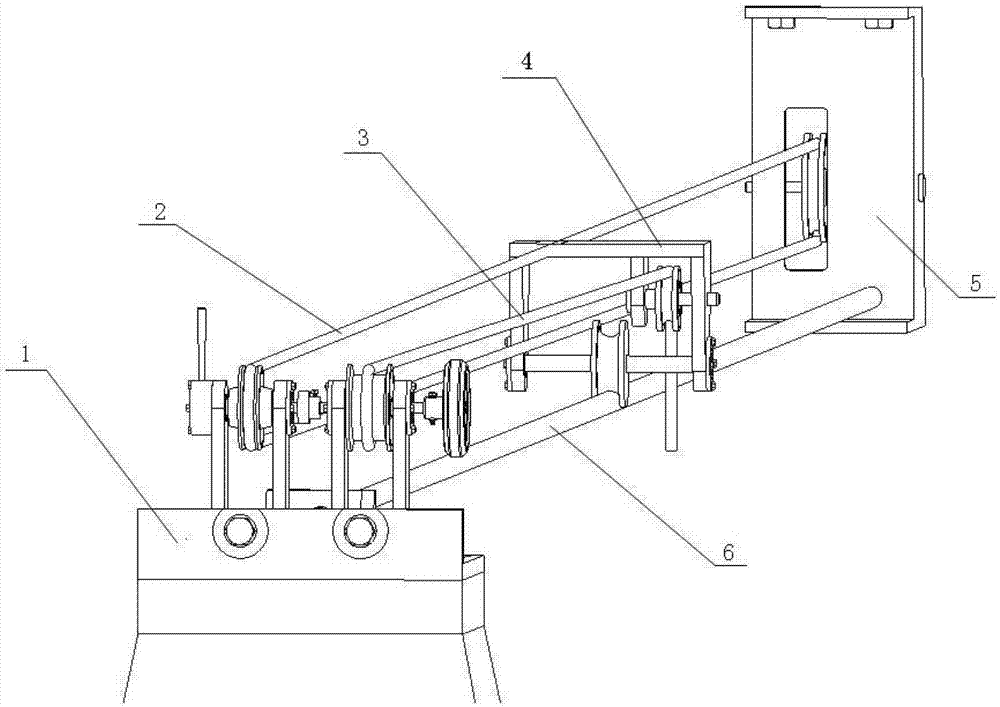

[0033] refer to figure 1 , figure 2 , image 3 The hydrological measuring equipment used in small water areas of the present invention is composed of a fixed mechanism 1, a transmission belt 2, a rope 3, a moving pulley frame 4, a suspension bracket 5, a guide cable 6, a base 7, a fixed plate 8, a tension bolt 9, and a support seat bolt 10. Fixed plate bolt 11, support seat 12, locking collar 13, pulley drive shaft 14, locking sleeve 15, handle 16, driving wheel 17, clutch 18, set bolt 19, main drive shaft 20, bearing end Cover 21, roller 22, bolt 23, control panel 24, splint 30, suspension frame 31, pulley pin shaft 32, drive belt driven wheel 33, bolt 34, steel beam 35, rolling bearing 36, circlip for hole 37, cotter pin 38, square hole sliding clutch 39, clutch set bolt 40 form. The fixing mechanism 1 is installed on the bank of the water area, and the suspension bracket 5 is fixedly installed on the opposite bank, and can also be installed above the water area accordin...

Embodiment approach

[0042] Figure 14 It is the second embodiment of the clutch between the pulley drive shaft and the main drive shaft of the present invention. The end of the pulley drive shaft and the main drive shaft is processed into a square shaft, and the square hole slip clutch 39 is installed on the pulley drive shaft , or installed on the end of the main drive shaft, it can slide on it. When the two shafts are connected in parallel, the sleeve slides to the middle position, and the set screw 40 of the square hole sliding clutch is tightened to prevent the sleeve from sliding. When the two shafts are separated, loosen the set screw 40 of the square hole sliding clutch, slide the sleeve to one end, and disengage from the other shaft end, so as to realize the independent movement of the two shafts. The suspension frame is fixedly connected to the steel beam through bolts 34, and the horizontal or vertical movement of the measuring device is realized through the transmission belt and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com