Test and evaluation method of density of fibers sucked from cigarettes or filter sticks

An evaluation method and fiber technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as harmfulness, and achieve the effect of simple method, easy promotion and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Cut the organic microporous filter membrane with a pore size of 20 μm into the same shape as the filter of the smoking machine;

[0039] 2. Cover the cut filter membrane on the filter sheet of the single-hole smoking machine, place the side with the filter membrane facing the cigarette, and insert a filter stick into the hole;

[0040] 3. Set the suction capacity of the smoking machine to 35 ml / mouth, set the suction time to 3s / mouth, and perform 10 mouthfuls of suction on the filter stick;

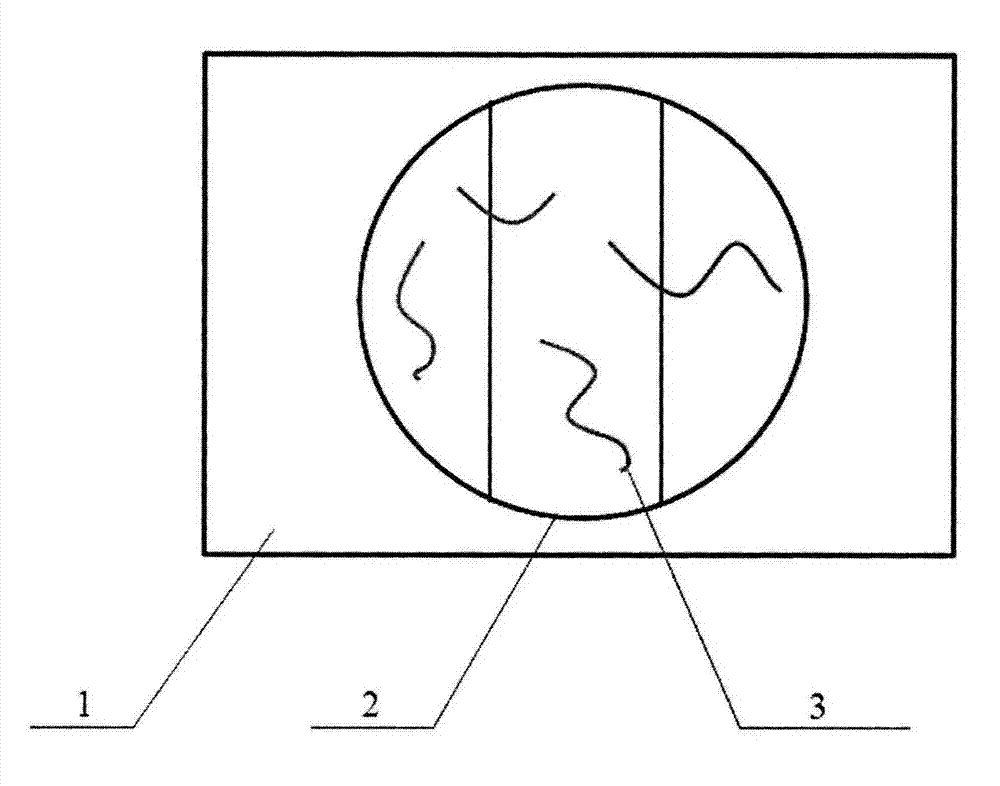

[0041] 4. After stopping the suction, take out the filter piece and filter membrane, carefully separate the filter membrane from the filter piece, then put the filter membrane between two clean glass plates, and divide three areas on the glass plate;

[0042] 5. Observe the fibers on the filter membrane under a microscope with a magnification of 30 times, and count the fibers in the three regions respectively. The total number of fibers on the filter membrane is 6. The schematic...

Embodiment 2

[0047] 1. Cut the organic microporous filter membrane with a pore size of 25 μm into the same shape as the filter of the suction device;

[0048] 2. Cover the cut filter membrane on the filter of the suction device, and place the side with the filter membrane facing the cigarette;

[0049] 3. Set the suction capacity of the suction device to 35 ml / puff, set the suction time to 4 s / puff, and smoke a cigarette for 10 puffs without lighting the cigarette;

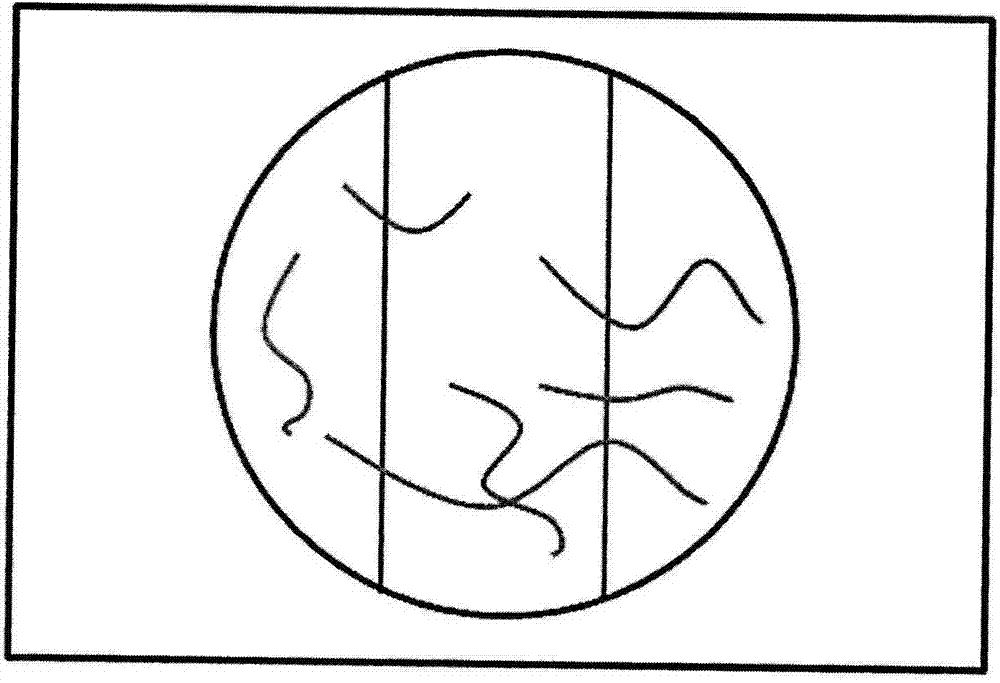

[0050] 4. After stopping the suction, take out the filter piece and filter membrane, carefully separate the filter membrane from the filter piece, then put the filter membrane between two clean glass plates, and divide three areas on the glass plate;

[0051] 5. Observe the fibers on the filter membrane under a microscope with a magnification of 40 times, and count the fibers in the three regions respectively. The total number of fibers on the filter membrane is 3. The schematic diagram is shown in image 3 ;

[0052] 6. Acc...

Embodiment 3

[0054] 1. Cut the microporous filter membrane with a pore size of 30 μm into the same shape as the filter of the smoking machine;

[0055] 2. Cover the cut filter film on the filter of the linear multi-channel smoking machine, place the side with the filter film facing the cigarette, and insert the cigarette into the channel with the filter;

[0056] 3. Set the suction volume of the cigarette machine to 55 ml / puff, set the puff time to 3s / puff, and smoke a cigarette for 20 puffs without lighting the cigarette;

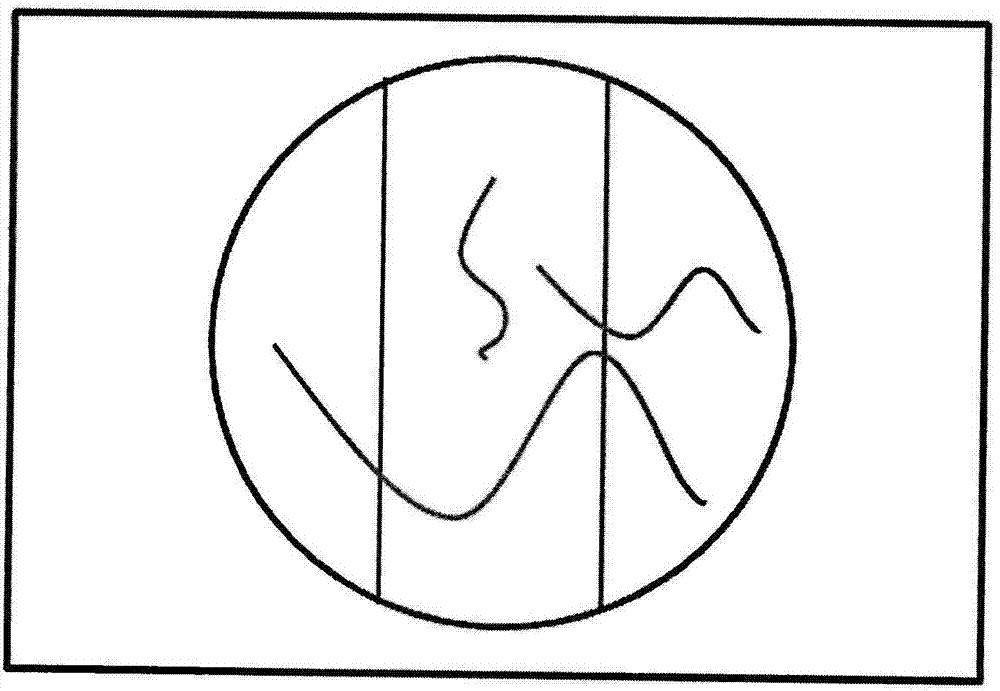

[0057] 4. After stopping the suction, take out the filter piece and filter membrane, carefully separate the filter membrane from the filter piece, then put the filter membrane between two clean glass plates, and divide three areas on the glass plate;

[0058] 5. Observe the fibers on the filter membrane under a microscope with a magnification of 30 times, and count the fibers in the three regions respectively. The total number of fibers on the filter membrane is 10. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com