Wind turbine generator gearbox lubricating oil on-line monitor and control platform based on ARM (advanced RISC machine)

A technology of gearbox oil and monitoring platform, applied in the direction of computer control, program control, general control system, etc., can solve the problems of under-maintenance, over-maintenance, blind maintenance, etc., to avoid unrepresentative sampling and secondary pollution, anti- The effect of enhanced interference capability and good scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings.

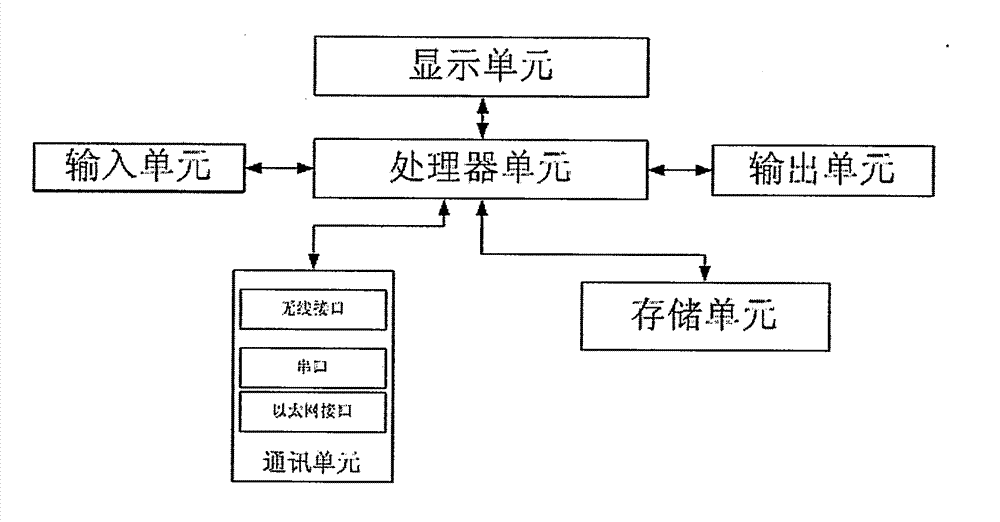

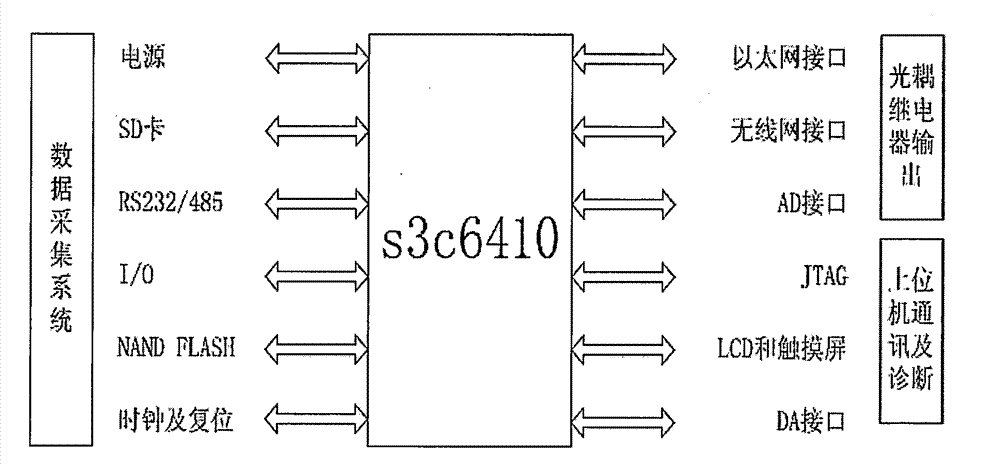

[0018] Control attached figure 1 and attached figure 2 , the present invention is based on ARM and Linux integrated data acquisition, touch screen, SQLite database, RS232 / RS485 communication, wireless communication, Ethernet communication, A / D and other functions of the novel wind power gearbox oil quality monitoring platform, the hardware includes a processor unit , Display touch screen unit, input unit, output unit, storage unit, communication unit, power supply unit, software includes Linux operating system, data processing algorithm, Qt interface, SQLite database, communication, etc. .

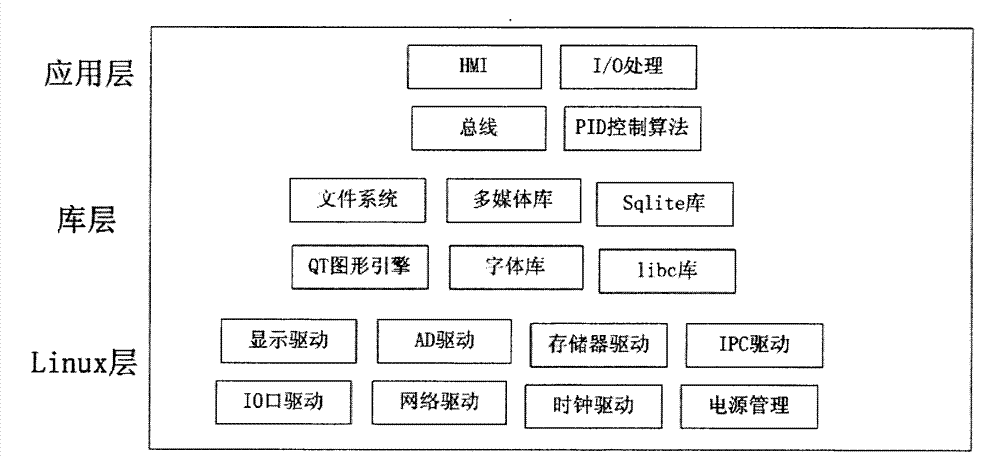

[0019] Control attached image 3 , the software structure mainly includes system programs and application programs. The former completes the system's task scheduling, storage allocation, clock management, interrupt management, and provides use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com