Valve assembly

A valve and valve stem technology, which is applied to valve devices, lift valves, engine components, etc., can solve the problems of valve weakening, entry, and increase construction costs, and achieve the effect of simplifying the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

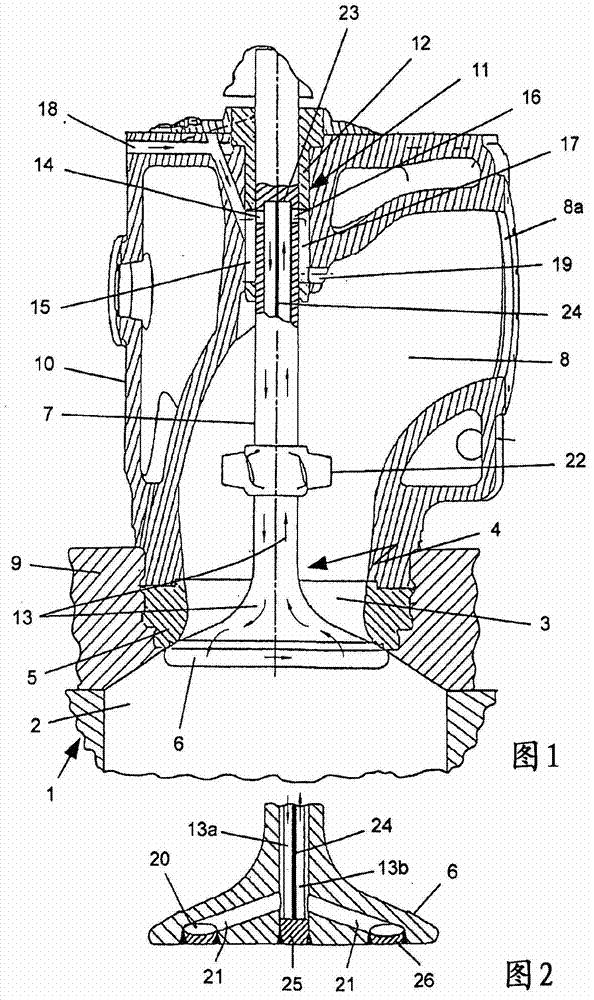

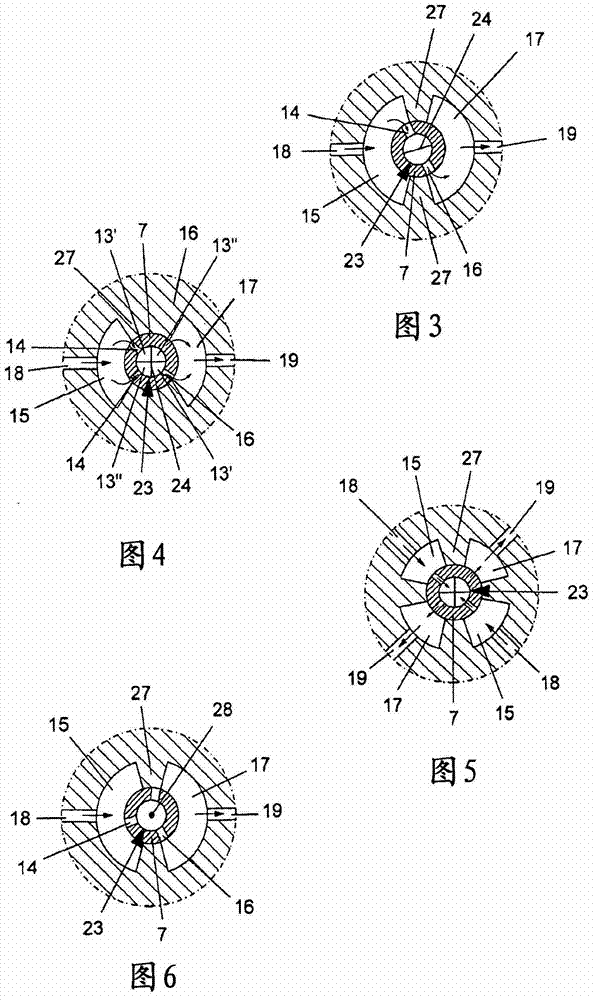

[0025] The main field of application of the invention is the exhaust valve arrangement of large two-stroke engines, especially large two-stroke diesel engines, as they are used for marine drives and the like. Engines of this type generally have an air intake for fresh gas arranged in the lower area of each cylinder and a respective centrally arranged exhaust gas outlet in the cylinder head of each cylinder, to which a valve is assigned . The exhaust valves arranged in the region of the upper cylinder are here subjected to a particularly high thermal load, so that cooling is expedient.

[0026] exist figure 1The cylinder 1 shown in the figure delimits a working chamber 2, which can be supplied with scavenging gas in its lower region, not shown, via an inlet controllable by a piston, also not shown, and whose upper boundary contains an exhaust gas outlet 3. Assigned to the exhaust gas outlet is an exhaust valve, hereinafter referred to as valve 4, which is designed as a pop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com