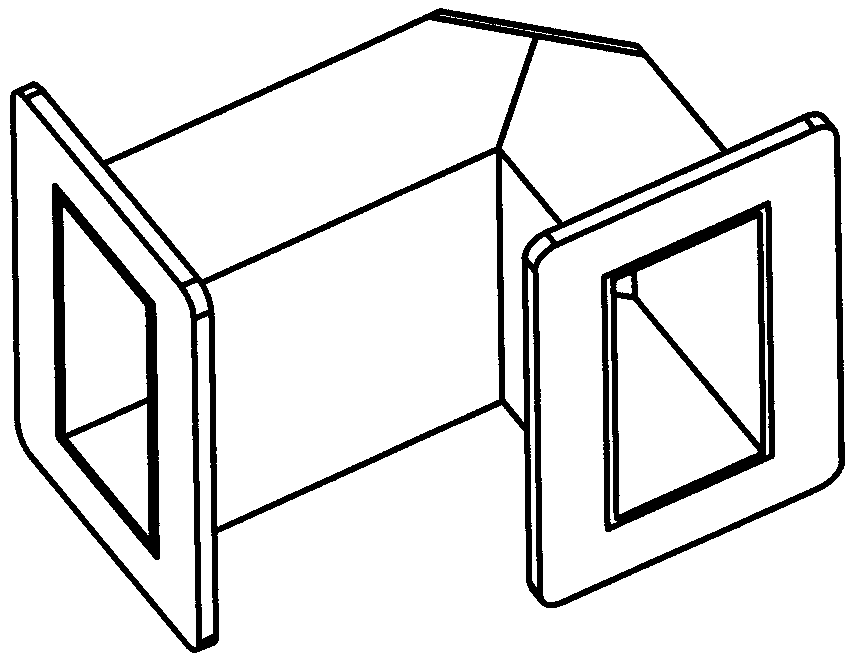

Bending type forming method of corner cut waveguide bend

A technology of bending waveguide and chamfering, which is applied in the field of bending and forming of chamfered and curved waveguides, can solve the problems of difficult welding, many splicing surfaces, and high probability of welding defects, so as to improve the forming accuracy of the inner cavity and reduce the size of the inner cavity Error, the effect of reducing the probability of misalignment defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

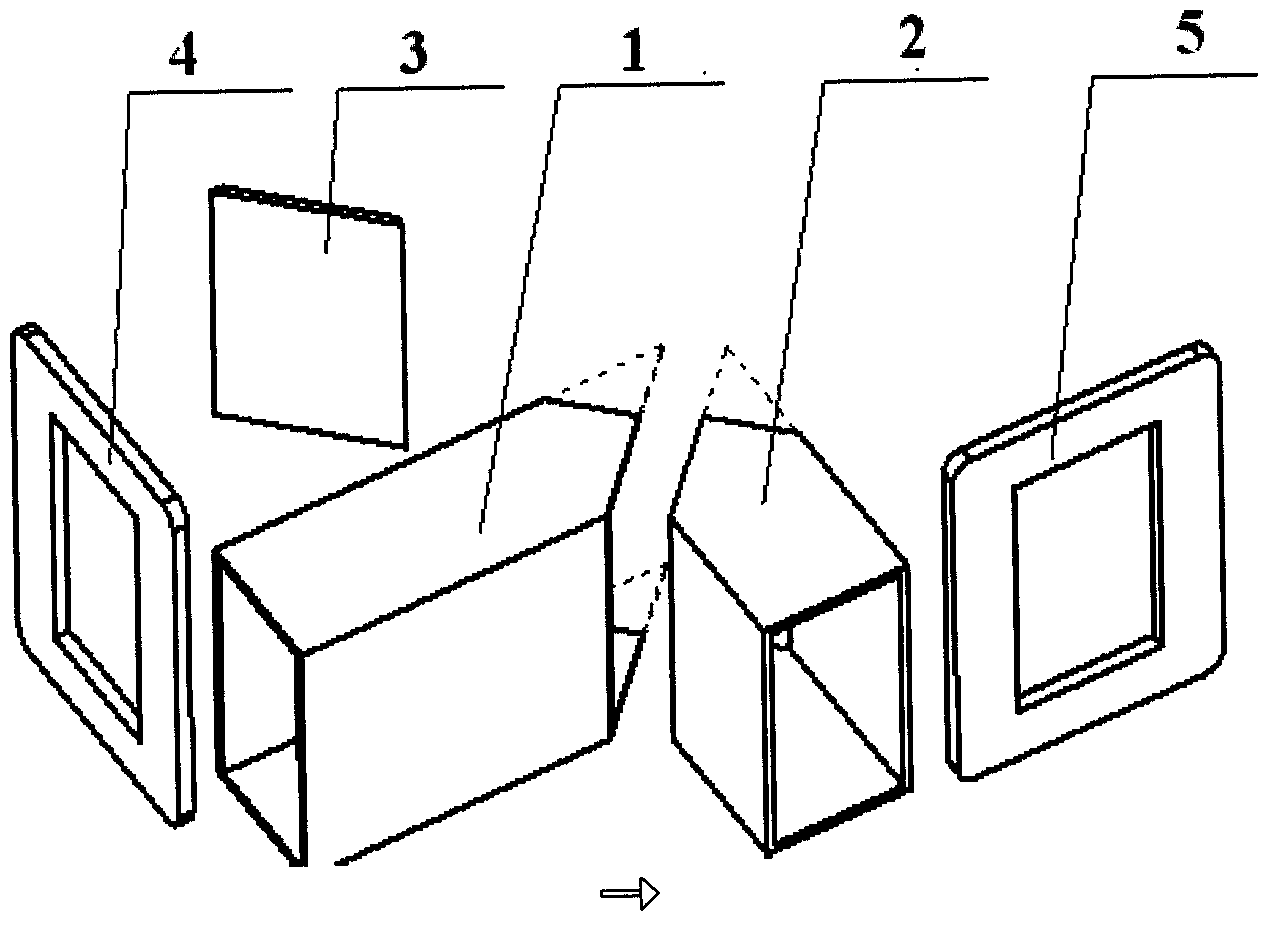

[0038] The bending forming method of rust-proof aluminum alloy LF21 for aluminum waveguide material, the specific steps are as follows:

[0039] 1) Processing the waveguide:

[0040] The material is made of aluminum alloy standard model BJ40 rectangular waveguide, with an inner cavity width of 58.17mm, a height of 29.08mm, and a wall thickness of 1.5mm.

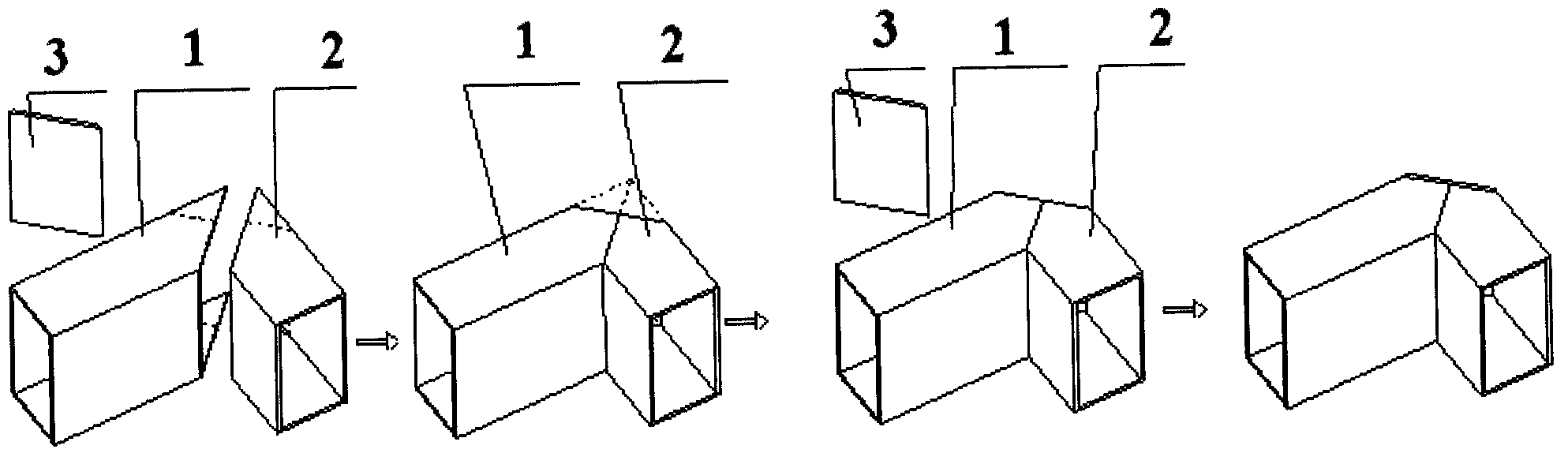

[0041] like Figure 4 As shown, the triangular bending groove A10 and the triangular bending groove B11 are processed on the rear surface of the aluminum waveguide, and the waveguide is divided into three parts in the length direction, the middle part is the folding area 9, and the two ends are the waveguide A7 and the waveguide respectively. Tube B8; B0=50.51mm is the length of the inner surface of the folding area 9, B is the distance between the triangular bending groove A10 and the triangular bending groove B11, after considering the bending stretch and the weld gap, take B=50.91mm .

[0042] like Figure 5 As shown, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com