Flexible grinding and polishing compound arc sand wheel

A grinding wheel, grinding and polishing technology, applied in the field of grinding wheels, can solve the problems of high manufacturing process requirements for hole-type flexible grinding wheels, inability to process aspheric workpieces, and high manufacturing difficulty, so as to improve material removal rate and surface shape accuracy, and expand processing efficiency Part and processing efficiency are high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment is used for grinding processing.

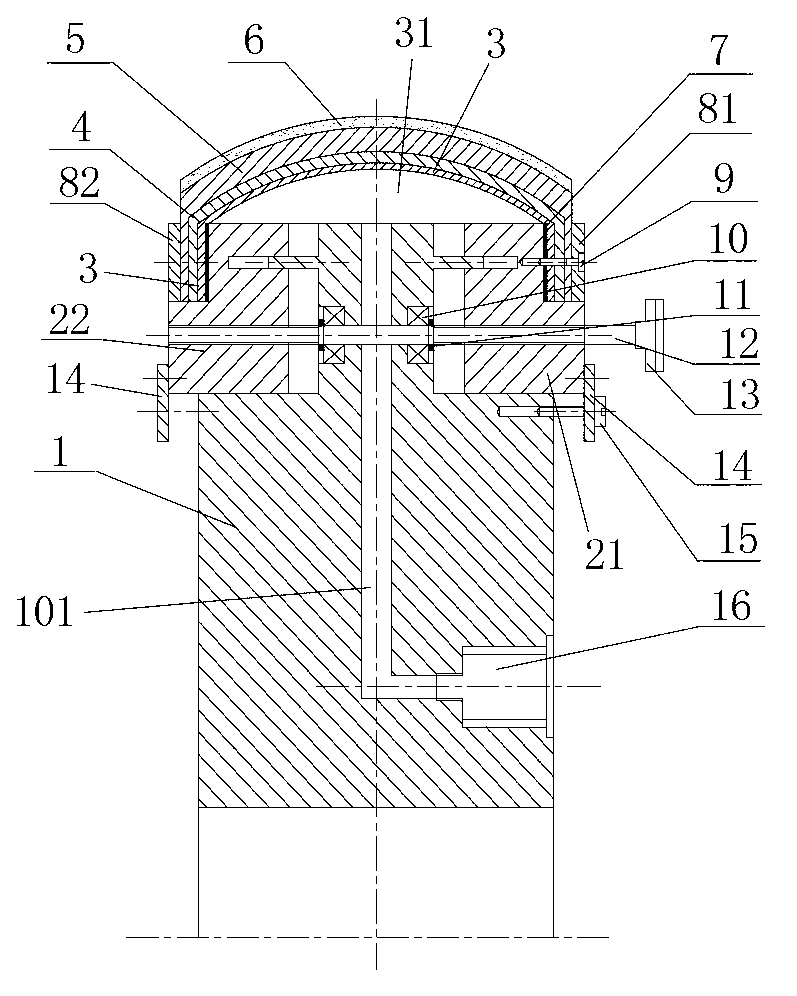

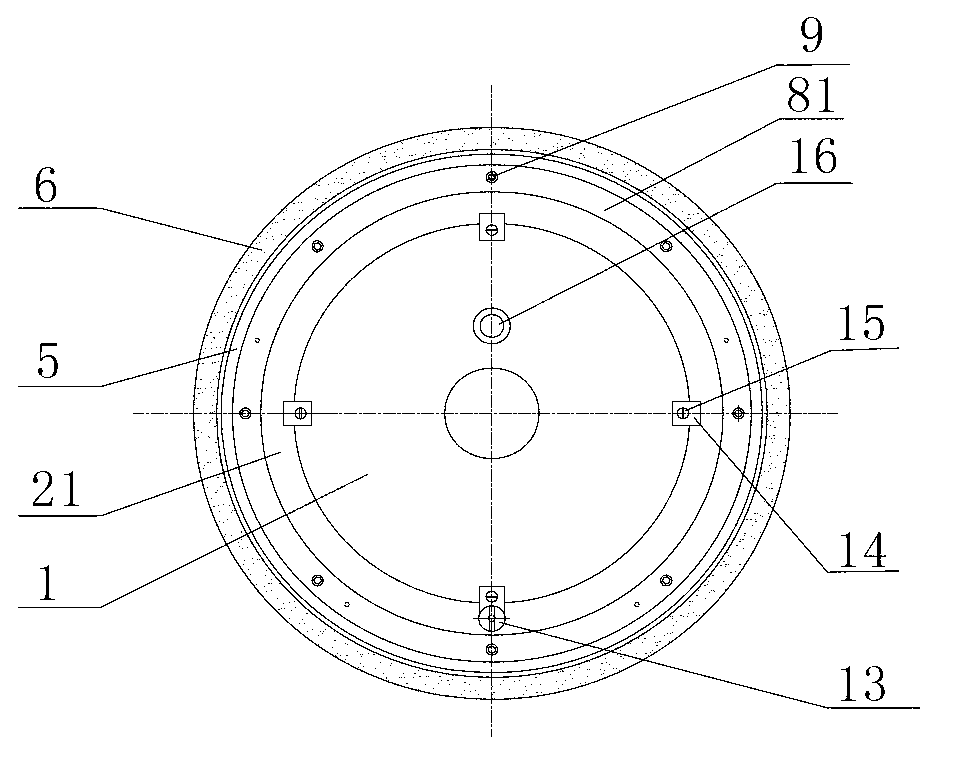

[0023] see figure 1 and 2 , The present invention is provided with grinding wheel main body 1, air valve 16, airbag arc adjustment device, annular airbag 3, grinding and polishing material ring and pressing device.

[0024] The main body of the grinding wheel 1 is provided with an air channel 101 , and the air valve 16 is located in the air channel 101 . The inner end of the air channel 101 communicates with the inner cavity 31 of the annular air bag 3 . The air bag arc adjustment device is provided with a front air bag arc adjustment ring 21, a rear air bag arc adjustment ring 22 and an adjustment drive screw 12, and the adjustment drive screw 12 ends are provided with a knob 13. The front airbag arc adjustment ring 21 is nested on the front end surface of the grinding wheel main body 1, the rear air bag arc adjustment ring 22 is nested on the rear end surface of the grinding wheel main body 1, the front air bag arc ...

Embodiment 2

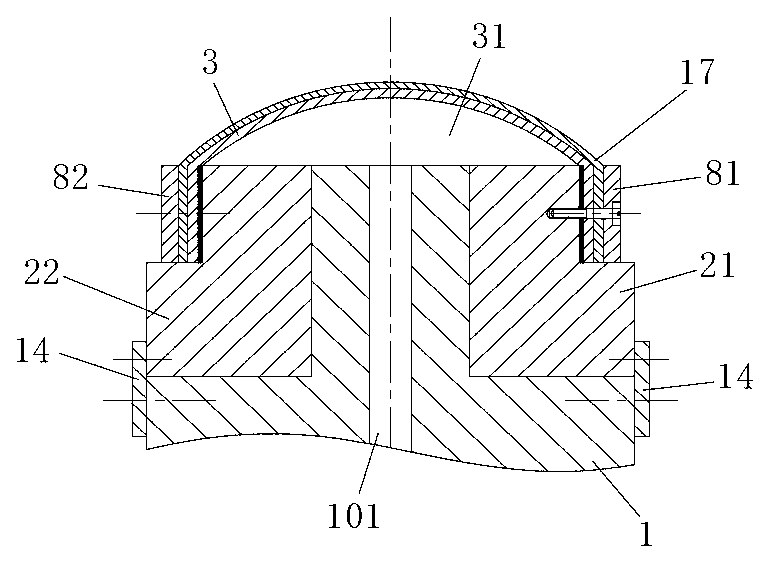

[0027] This embodiment is used for polishing.

[0028] see image 3 , similar to Embodiment 1, the difference is that the grinding and polishing material ring is a polishing washer 17, and the material of the polishing washer 17 is polyurethane. The rest of the symbols correspond to those in Example 1.

[0029] During polishing, the abrasive belt 6, the trimming rubber layer 5 and the hard rubber layer 4 in Example 1 are removed, the annular airbag 3 is kept, and the polishing pad 17 is put on the annular airbag 3. By adjusting the pressure of the annular airbag 3, the stiffness of the airbag 3 can be adjusted. According to different processes, the inflation pressure can be reasonably selected to reduce subsurface damage and surface roughness, and improve material removal rate and surface shape accuracy.

[0030] see Figure 4 , in order to prevent the intermediate frequency error generated by the workpiece P to be processed by the grinding wheel (represented by the label 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com