Staged homogenization heat treatment method for improving microstructure and performances of Zr-containing 7xxx aluminum alloy

A homogeneous heat treatment and aluminum alloy technology, applied in the homogeneous heat treatment of 7xxx series aluminum alloy structure and properties, the field of heat treatment of 7xxx series (Al-Zn-Mg-Cu) aluminum alloys, can solve the problem that is difficult to control, microstructure Imperfect, uneven distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

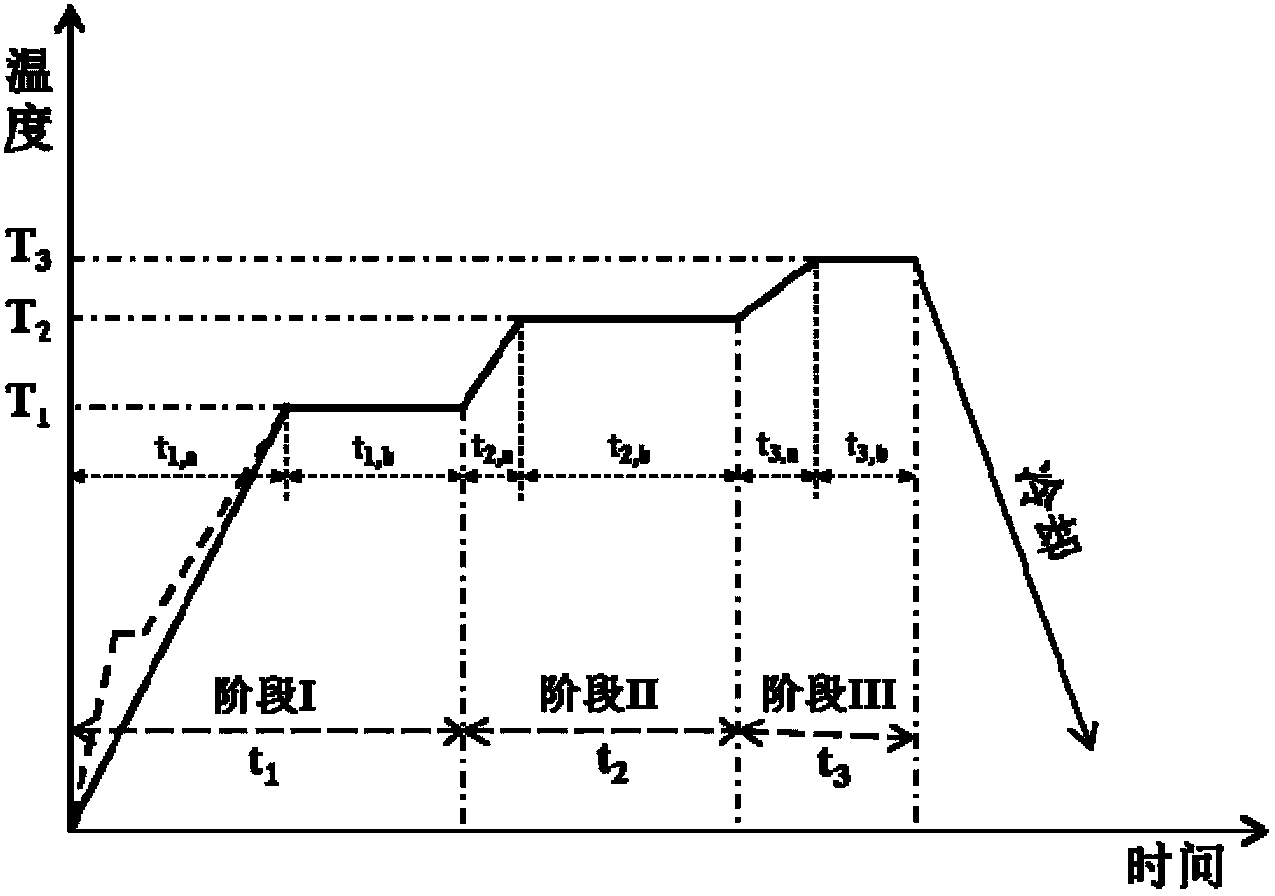

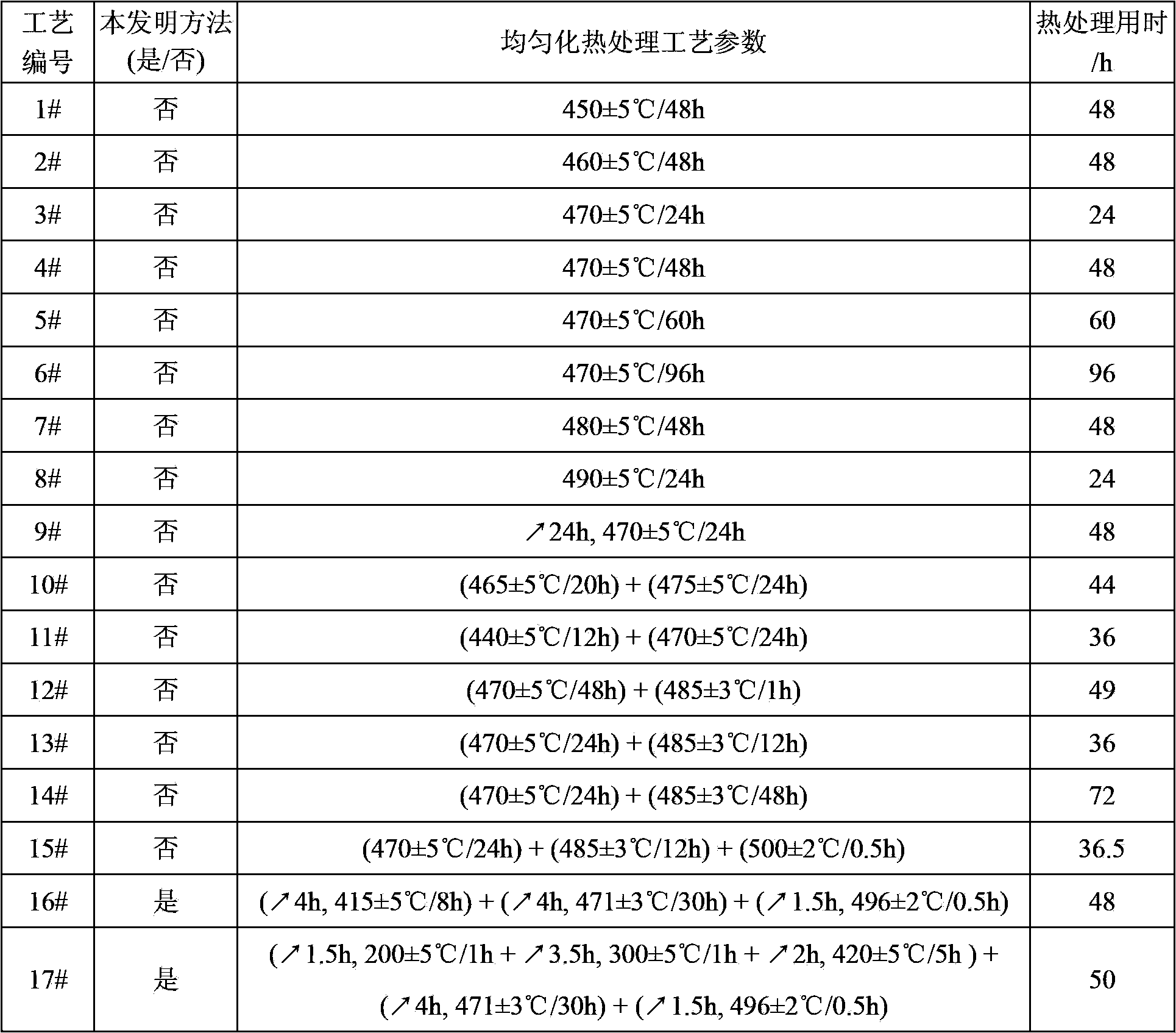

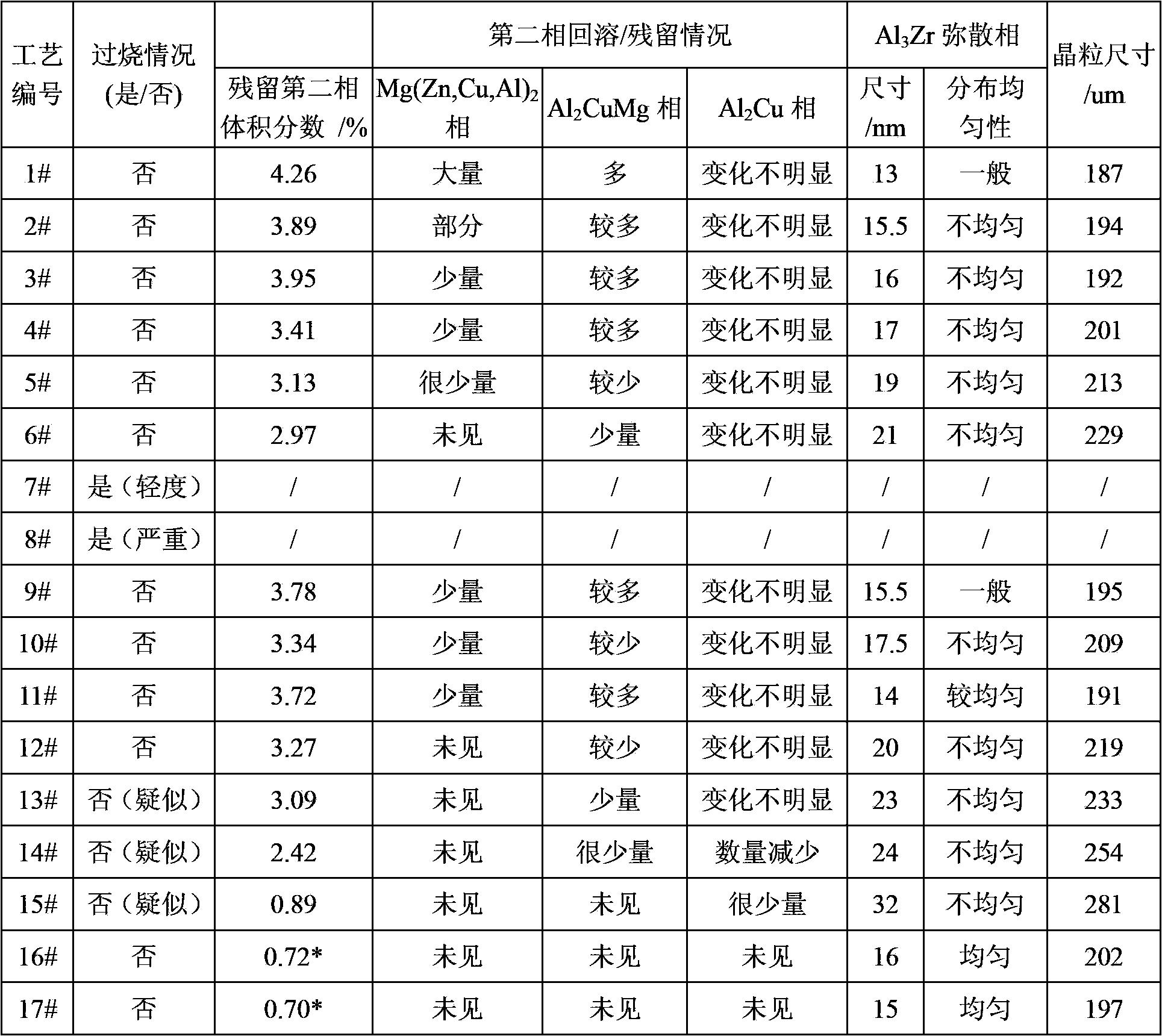

[0036] This example takes the 7050 / 7150 alloy (Al-6.4Zn-2.3Mg-2.2Cu-0.12Zr (wt%)) 280mm thick flat ingot as the research object. The 7050 / 7150 alloy ingots were prepared by semi-continuous casting under industrial conditions. Block samples were cut from the ingots and subjected to homogenization heat treatment tests of different schemes. The homogenization heat treatment system is shown in Table 1. Immediately after the homogenization treatment is completed, water cooling is performed to obtain the characteristic morphology of the structure reflecting the homogenization effect of the alloy, so as to avoid the influence of a large amount of precipitation of precipitation during the slow cooling process of the alloy and the second relative result analysis. Analytical tests were carried out in accordance with relevant standards, and the samples subjected to different homogenization treatments were subjected to tissue analysis. The results are shown in Table 2.

[0037] Table 1 70...

Embodiment 2

[0044] In this example, a round ingot of 7449 alloy (Al-8.2Zn-2.2Mg-1.8Cu-0.14Zr (wt%)) φ630mm is taken as the research object. The 7449 alloy ingot was prepared by semi-continuous casting under industrial conditions. Block samples were cut from the ingot and subjected to homogenization heat treatment tests of different schemes. The homogenization heat treatment system is shown in Table 3. Immediately after the homogenization treatment is completed, water cooling is performed to obtain the characteristic morphology of the structure reflecting the homogenization effect of the alloy, so as to avoid the influence of a large amount of precipitation of precipitation during the slow cooling process of the alloy and the second relative result analysis. Analytical tests were carried out in accordance with relevant standards, and the samples subjected to different homogenization treatments were subjected to tissue analysis. The results are shown in Table 4.

[0045] Table 3 7449 alloy ...

Embodiment 3

[0053] This example takes 7B85 alloy (Al-7.5Zn-1.7Mg-1.4Cu-0.12Zr (wt%)) 280mm thick slab as the research object. The 7B85 alloy ingot was prepared by semi-continuous casting under industrial conditions. Block samples were cut from the ingot and subjected to homogenization heat treatment tests of different schemes. The homogenization heat treatment system is shown in Table 5. Immediately after the homogenization treatment is completed, water cooling is performed to obtain the characteristic morphology of the structure reflecting the homogenization effect of the alloy, so as to avoid the influence of a large amount of precipitation of precipitation during the slow cooling process of the alloy and the second relative result analysis. Analytical tests were carried out in accordance with relevant standards, and the samples subjected to different homogenization treatments were subjected to tissue analysis, and the results are shown in Table 6.

[0054] Table 5 7B85 alloy homogeniza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com