Moisture-proof agent for paper surface and preparation method for moisture-proof agent

A moisture-proof agent and paper technology, applied in papermaking, textiles and papermaking, fiber raw material processing, etc., can solve problems affecting product quality, sales of finished paper, and physical indicators of finished paper, so as to save costs and energy costs, Good moisture index, quality assurance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

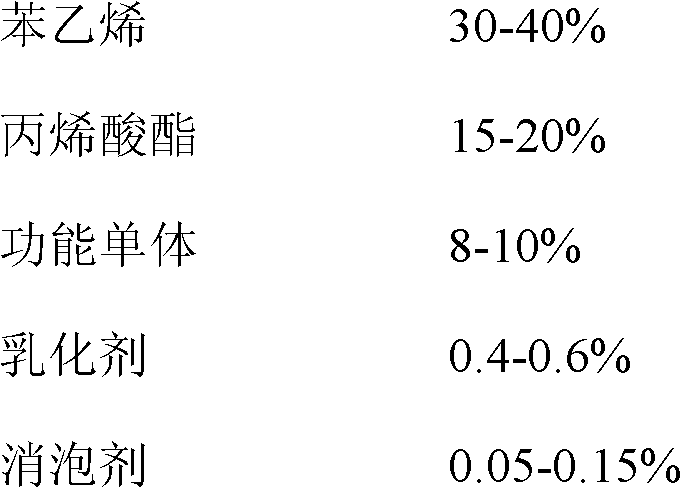

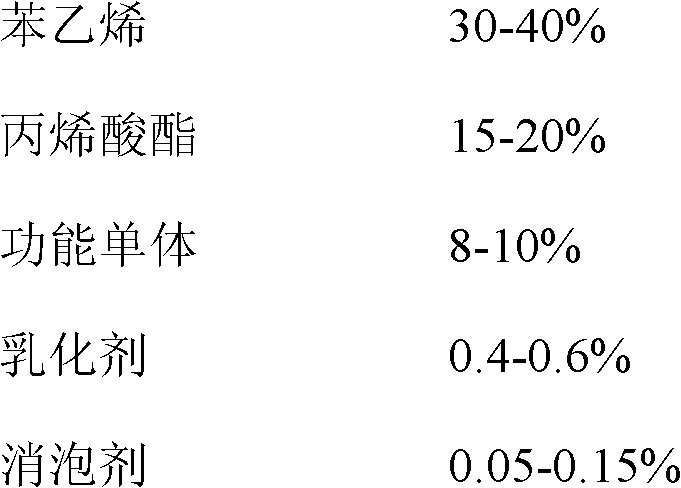

Embodiment 1

[0019] Dissolve starch into 8% liquid, mix with 30% styrene and 20% acrylate, pour into the emulsification tank successively, stir, heat up, the temperature reaches 45°C, emulsify for 15 minutes, lift it into the reaction tank, add 5% paraffin , 1.5% of alkyl ketene dimer, at stirring speed 180r / min, reaction temperature 75 ℃, reaction time 1.5h, holding time 2h, put into cooling tank then, and add emulsifier sodium stearate ( 0.5%), antifoaming agent simethicone (0.1%).

[0020] In the process of producing cardboard paper, after the cardboard paper passes through the pre-drying section, the surface of the produced cardboard paper is coated with a moisture-proof agent on the surface of the produced cardboard paper, and then passes through the post-drying section to obtain the The water content of the cardboard paper is 92% after inspection, which is in line with the quality system standard formulated by the state.

Embodiment 2

[0022] Dissolve starch into a 7% liquid, mix with 40% styrene and 15% acrylate, pour into the emulsification tank in turn, stir, heat up, until the temperature reaches 45°C, emulsify for 10 minutes, lift it into the reaction tank, add 3% paraffin , alkyl ketene dimer 2.0%, put into cooling tank then at stirring speed 150r / min, reaction temperature 65 ℃, reaction time 2h, holding time 1.5h, and add emulsifier sodium stearate ( 0.5%), antifoaming agent simethicone (0.1%).

[0023] In the process of producing cardboard paper, after the cardboard paper passes through the pre-drying section, the surface of the produced cardboard paper is coated with a moisture-proof agent on the surface of the produced cardboard paper, and then passes through the post-drying section to obtain the The water content of the container board is 93% after inspection, which meets the quality system standard formulated by the state.

Embodiment 3

[0025] Dissolve starch into 9% liquid, mix with 35% styrene and 17% acrylate, pour into the emulsification tank successively, stir and heat up, until the temperature reaches 45°C, emulsify for 15 minutes, lift it into the reaction tank, add 4% paraffin , alkyl ketene dimer 1.8%, at a stirring speed of 200r / min, a reaction temperature of 85°C, a reaction time of 2.5h, and a holding time of 2.5h, it is then put into the cooling tank, and the emulsifier sodium stearate is added to the pipeline (0.5%), antifoaming agent simethicone (0.1%).

[0026] In the process of producing cardboard paper, after the cardboard paper passes through the pre-drying section, the surface of the produced cardboard paper is coated with a moisture-proof agent on the surface of the produced cardboard paper, and then passes through the post-drying section to obtain the The water content of the cardboard paper is 92% after inspection, which is in line with the quality system standard formulated by the stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com