Precast concrete pile and manufacturing method thereof

A technology of concrete prefabricated piles and concrete, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering. It can solve the problems of limited application of machine-made sand and high cost of natural sand, and achieve the goal of improving resource utilization, improving work performance, and reducing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

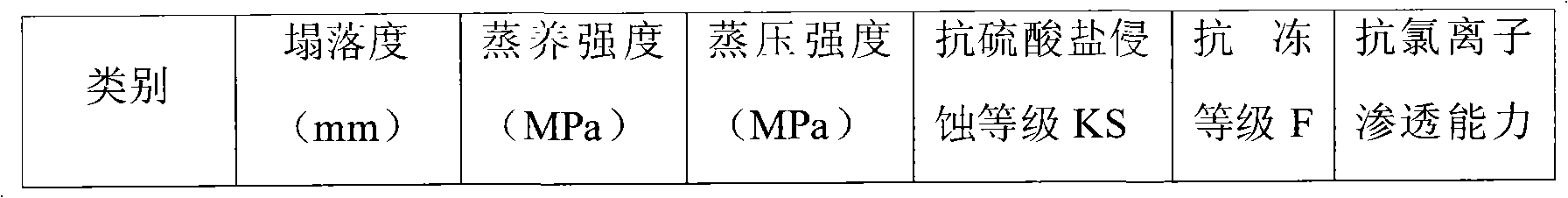

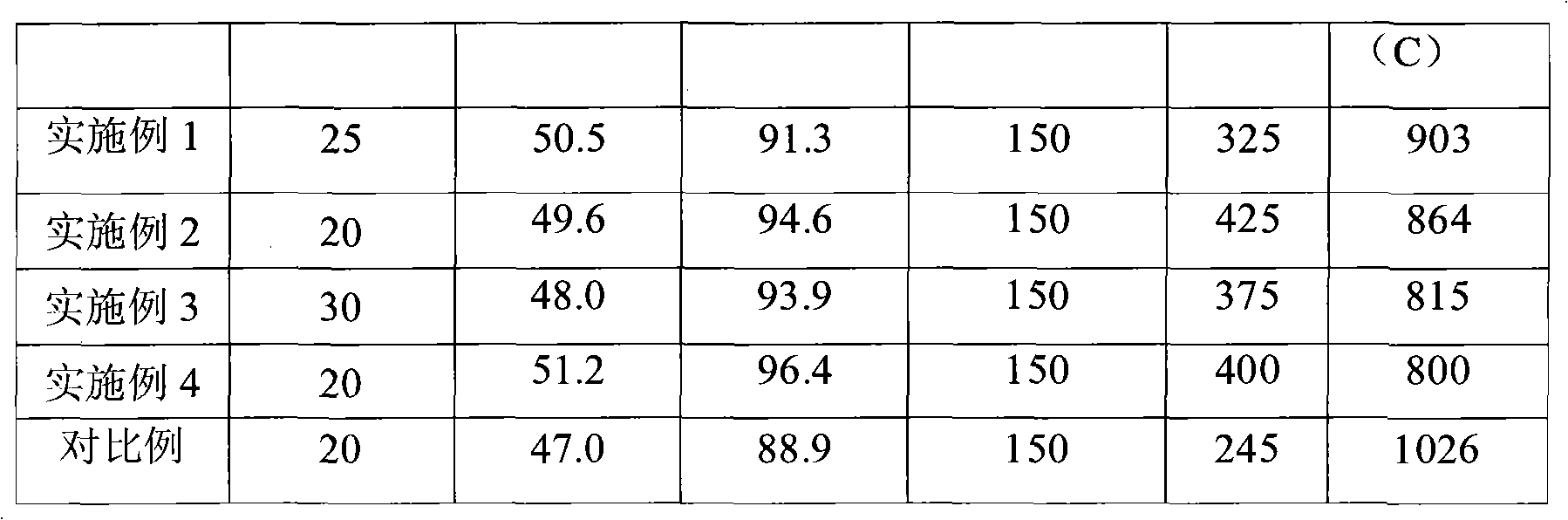

Embodiment 1

[0038] The raw materials of concrete include: cementitious material, fine aggregate, coarse aggregate, admixture and water. The total content of cementitious material is 440kg / m 3 , It is composed of 55wt% cement and 45wt% silica sand powder, among which the cement is Portland cement with strength grade 42.5, and the specific surface area of silica sand powder is 300m 2 / kg; water-binder ratio is 0.34; sand ratio is 36%; fine aggregate is 95wt% natural sand and 5wt% machine-made sand, among which the fineness modulus of natural sand is 2.8, the mud content is ≤2.0wt%, machine-made sand It is prepared from mine tailings by mechanical crushing, grading screening and dust removal treatment. The fineness modulus is 3.2. The particle gradation meets the requirements of the standard sand II zone. The stone powder content is 4wt%; the coarse aggregate is crushed stone. ~25mm continuous gradation, crushing value is 8%, needle-like particle content is 7%; the admixture is a naphthalene...

Embodiment 2

[0040] The raw materials of concrete include: cementitious material, fine aggregate, coarse aggregate, admixture, and water. The total content of cementitious material is 480kg / m 3 , It is composed of 80wt% cement and 20wt% fly ash. The cement is ordinary Portland cement with a strength grade of 52.5. The fly ash meets the requirements of grade II fly ash in the GB / T1596 standard; the water-binder ratio is 0.36; The sand ratio is 40%; the fine aggregate is 30wt% natural sand and 70wt% machine-made sand. The natural sand has a fineness modulus of 2.9 and a mud content of ≤2.0% by weight. The machine-made sand is mechanically crushed and graded by industrial waste residues. It is prepared with sieving and dust removal treatment, the fineness modulus is 3.4, the particle gradation meets the requirements of the standard sand II zone, the stone powder content is 5wt%; the coarse aggregate is crushed stone, 5-25mm continuous grading, crushing value It is 8%, and the content of needle...

Embodiment 3

[0042] The raw materials of concrete include: cementitious material, fine aggregate, coarse aggregate, admixture and water. The total content of cementitious material is 400kg / m3, composed of 100wt% cement, of which the cement is ordinary Portland cement with strength grade 42.5; the water-binder ratio is 0.40; the sand ratio is 30%; the fine aggregate is 100wt% machine-made sand , Among them, machine-made sand is made by mechanical crushing, grading screening and dust removal treatment of mine tailings, with a fineness modulus of 2.3, particle grading meets the requirements of standard sand I zone, and stone powder content of 8wt%; coarse aggregate It is crushed stone, 5~25mm continuous gradation, crushing value is 8%, needle-like particle content is 7%; admixture is polycarboxylate high-performance water reducing agent, solid content is the total weight of gelling material 0.5wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com