Surface luminous body realizing method with patterning function and device for realizing patterned luminescence

A surface luminous body and a technology of a realization method, applied in the field of optics, can solve problems such as waste of energy, environmental pollution, and only overall plane light emission, and achieve the effects of energy saving, low cost, and convenient graphic design changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

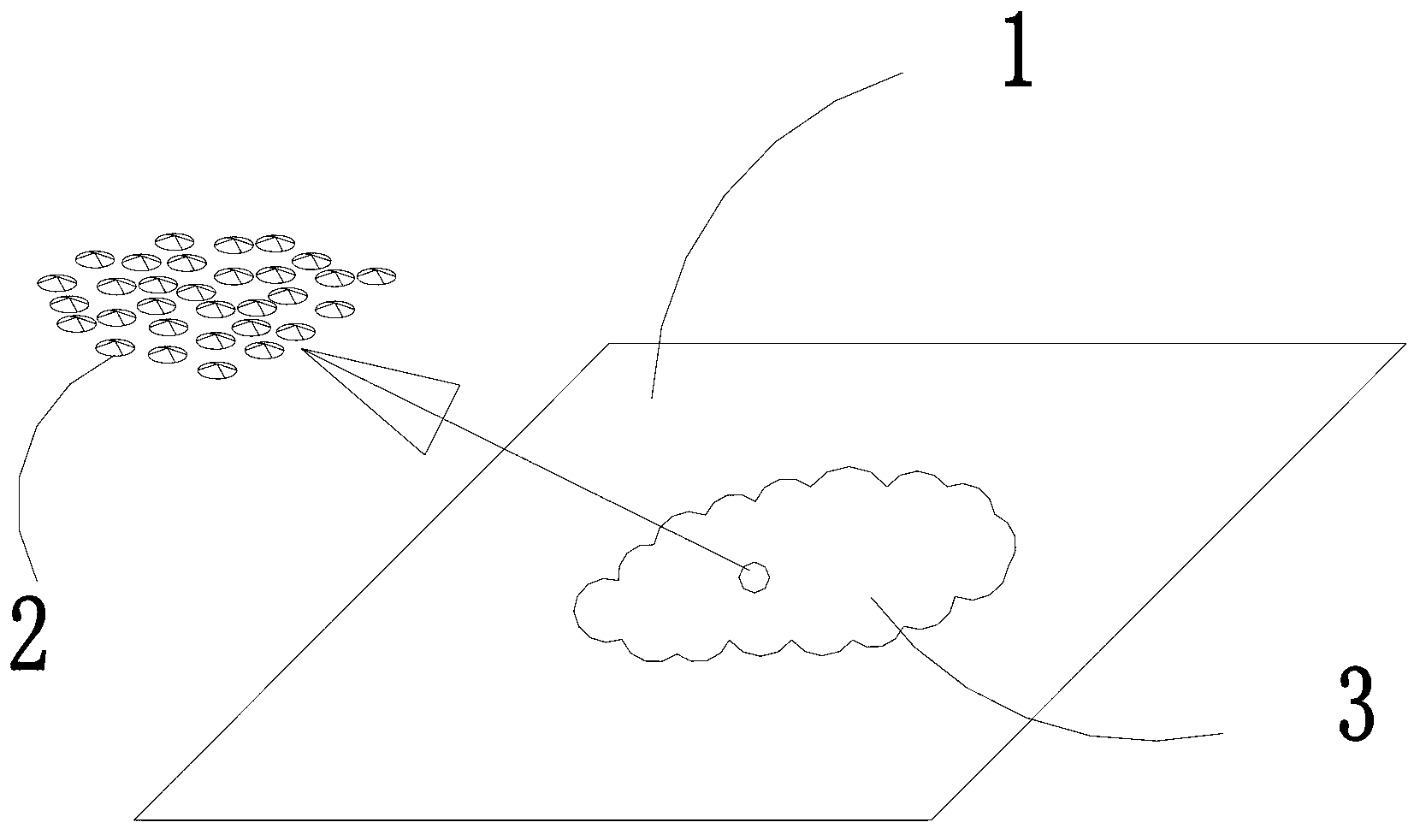

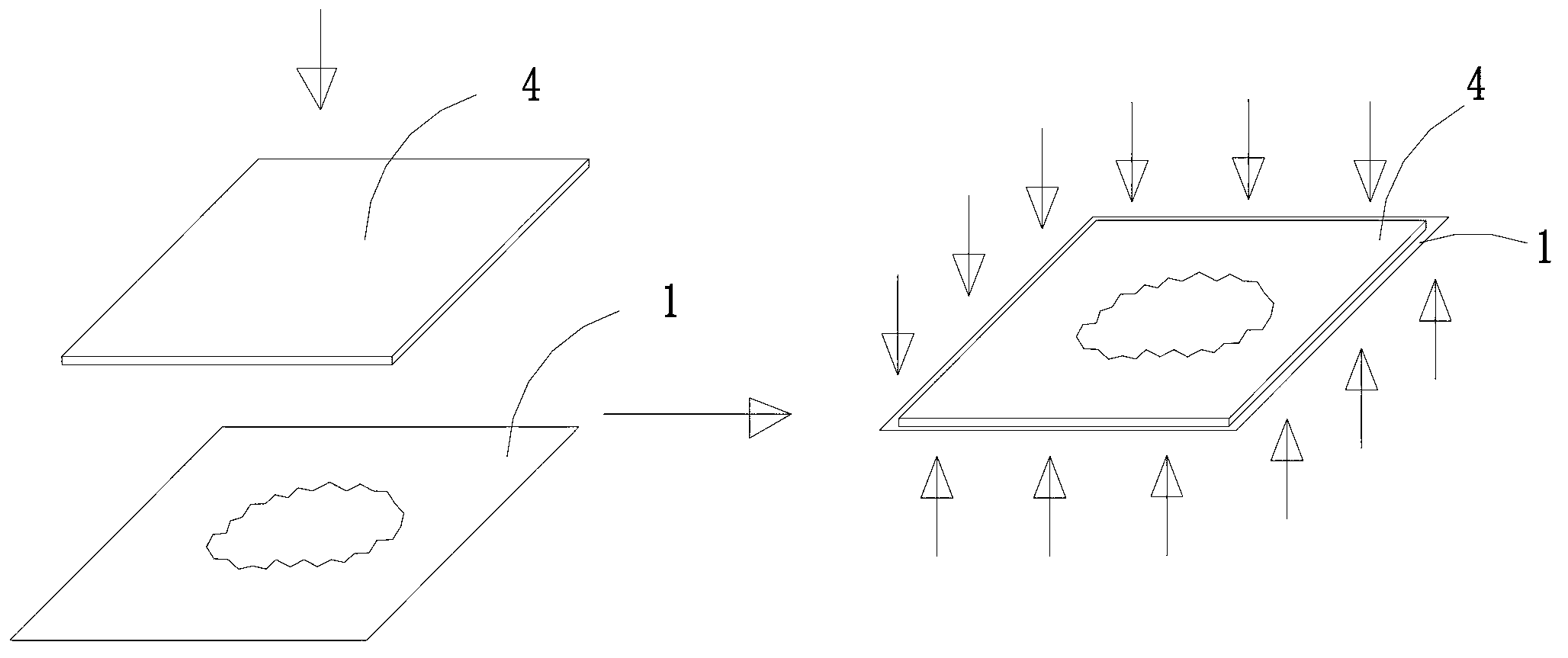

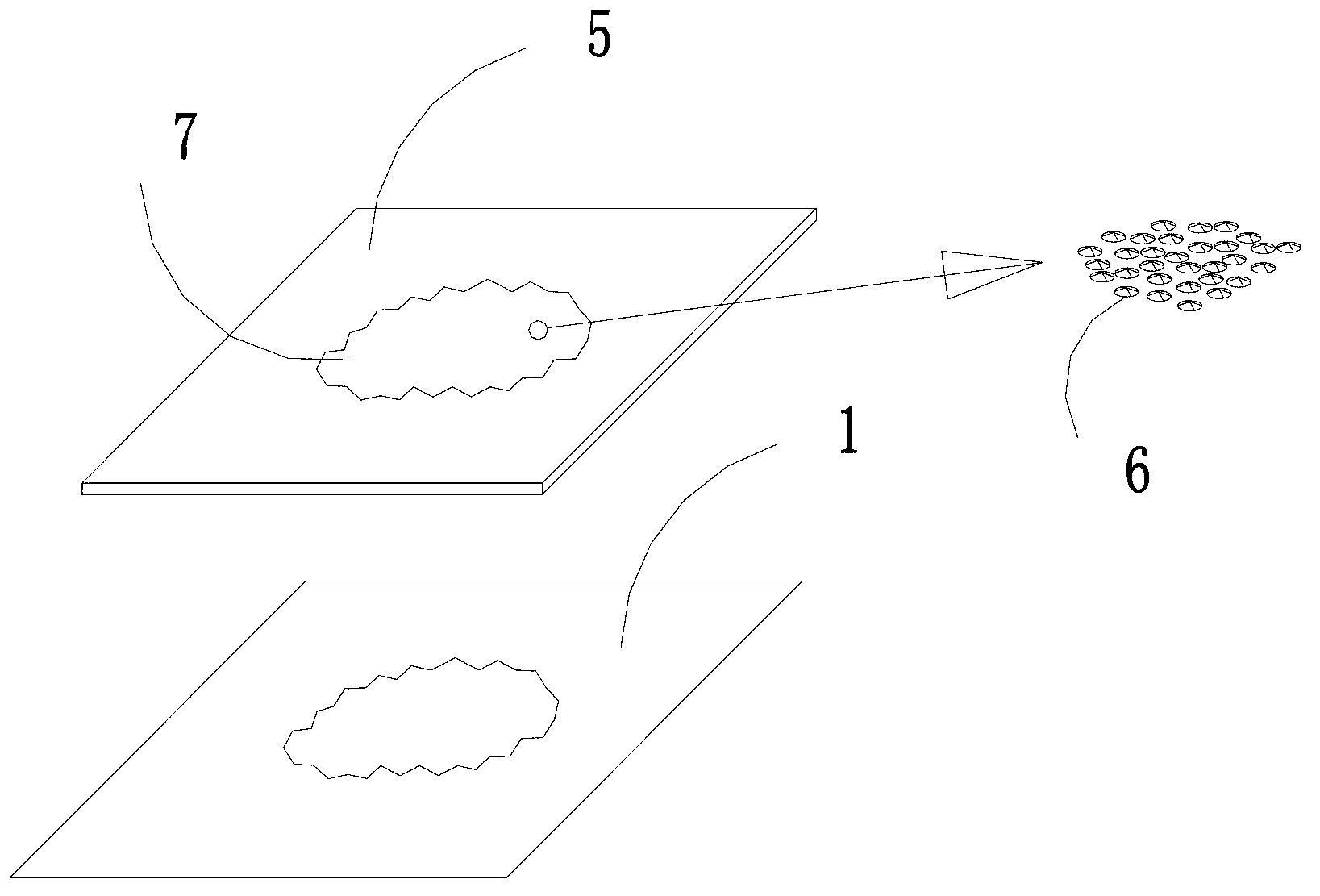

[0038] combine Figure 1 to Figure 3 As shown, a method for implementing a surface illuminant with graphics,

[0039] Step 1: making a metal mold core plate 1, with micro-optical elements 2 on the metal mold core plate 1, and the micro-optical elements 2 are arranged and assembled on the metal mold core plate 1 according to predetermined requirements to form a graphic outline 3;

[0040] The above-mentioned metal core plate 1 is obtained by the invention patent of 201210217175.9 filed by the same applicant on June 26, 2012. Graphical micro-structured optical elements are collectively produced on a metal mold core. In this embodiment, the optical elements on the metal mold core are transferred to the light-transmitting light guide by means of pressurization and heating. It is characterized by light guide Arbitrary luminescence patterns including overall planar luminescence can be realized quickly and at low cost on the body.

[0041] The prior patent mentioned in this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com