Multi-tube type minimum mixed-phase pressure measuring method and device

A miscible pressure and measurement method technology, which is applied in the field of petroleum physical property measurement and minimum miscible pressure measurement, can solve the problems of long measurement period, extended experiment period, pipeline corrosion and other problems of thin tube experiment, and achieve short measurement period, easy cleaning process, The effect of pipeline corrosion is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

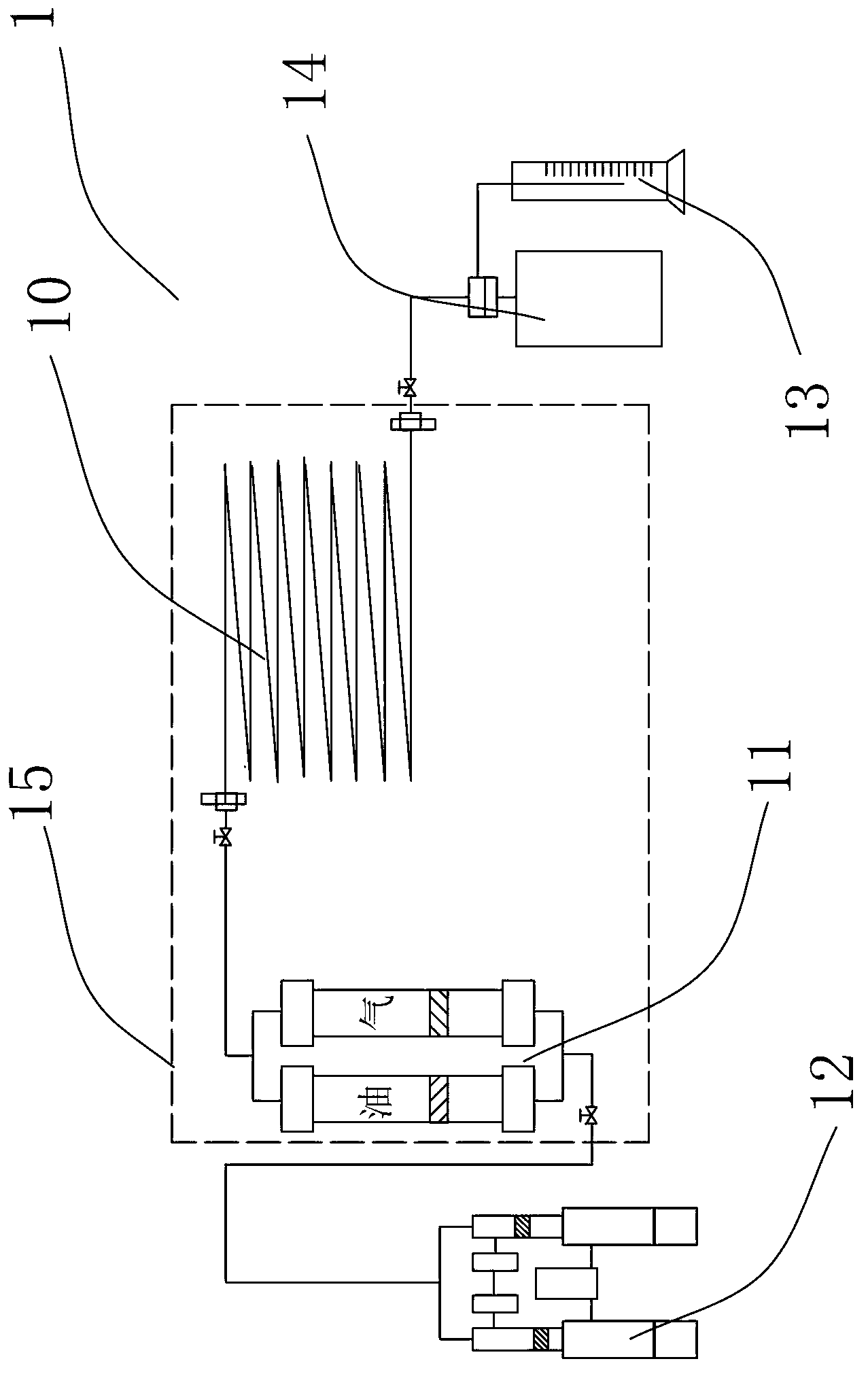

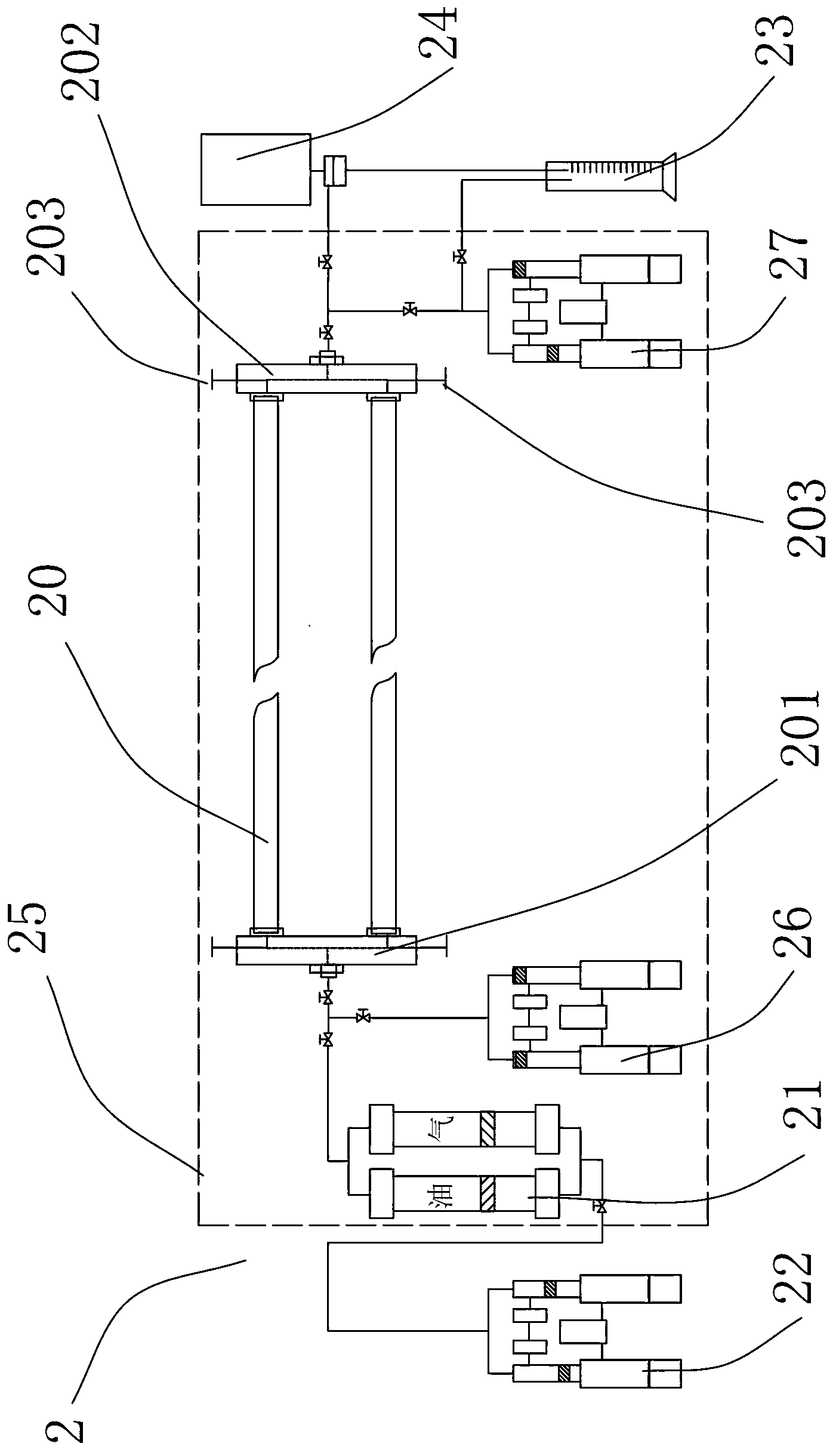

[0047] The present invention proposes a multi-tube type minimum miscible pressure measurement method, which mainly includes:

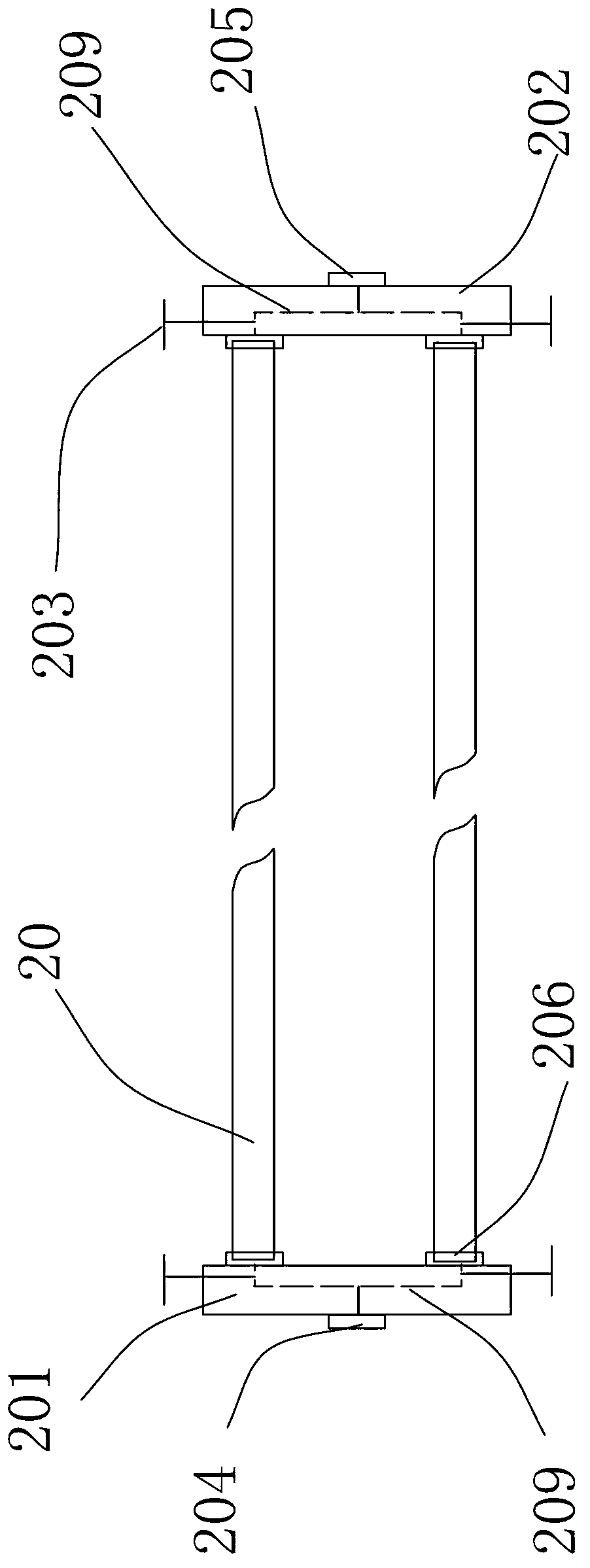

[0048] A. Capillary filling, filling each capillary with quartz sand that can simulate loose sandstone in the formation, adding filter plugs and pressure caps at both ends of the capillary;

[0049] B. Perform saturated oil operation on each thin tube;

[0050] C. The inlet end and the outlet end of the thin tube are respectively connected with a reciprocating pump;

[0051] D. Select one of the thin tubes, and carry out the gas flooding experiment under the first pressure condition, so that the gas and crude oil reciprocate at least once in a single thin tube, and the two phases are fully achieved by the influence of the pore structure in the thin tube. and obtain the fluid discharged from the thin tube under the first pressure condition, and obtain the recovery factor of the thin tube under the first pressure condition;

[0052] E. Select another thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com