Numerical simulation method for hydraulic fracture of core wall of rock-fill dam

A technology of hydraulic splitting and numerical simulation, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., and can solve problems such as inconsistent opinions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

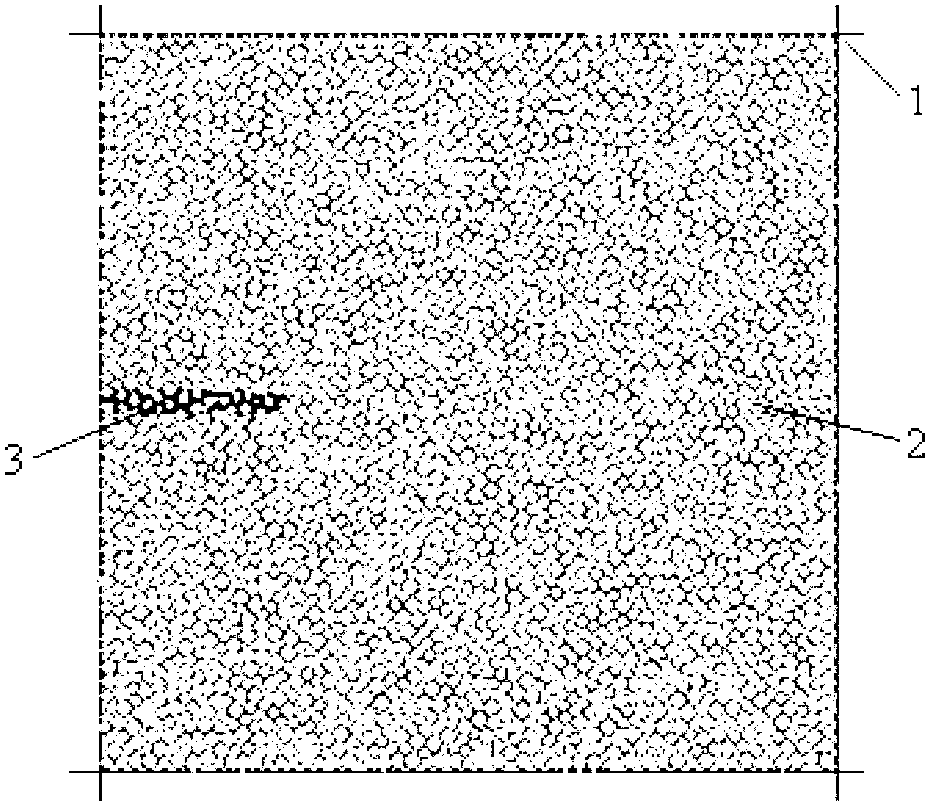

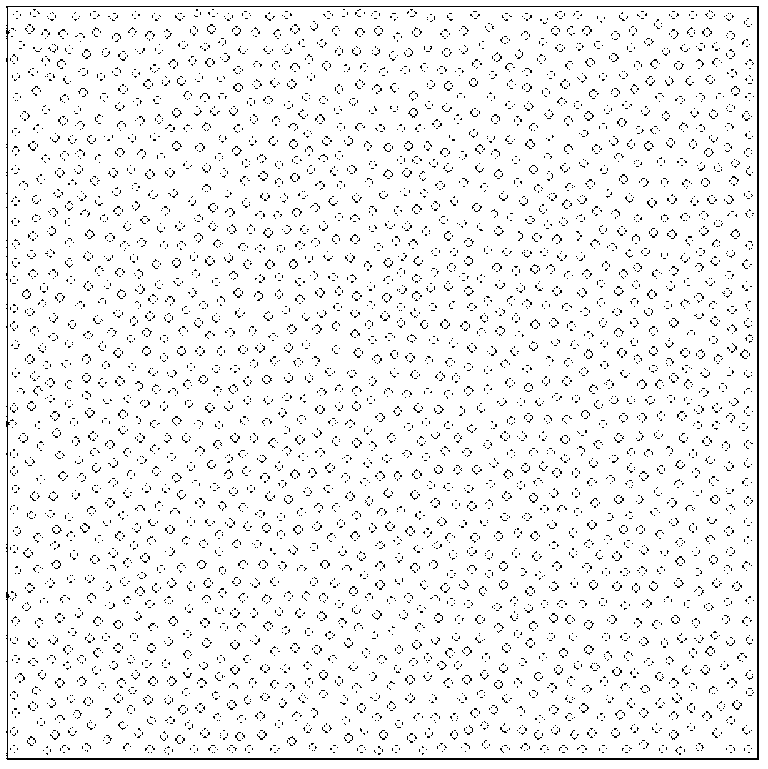

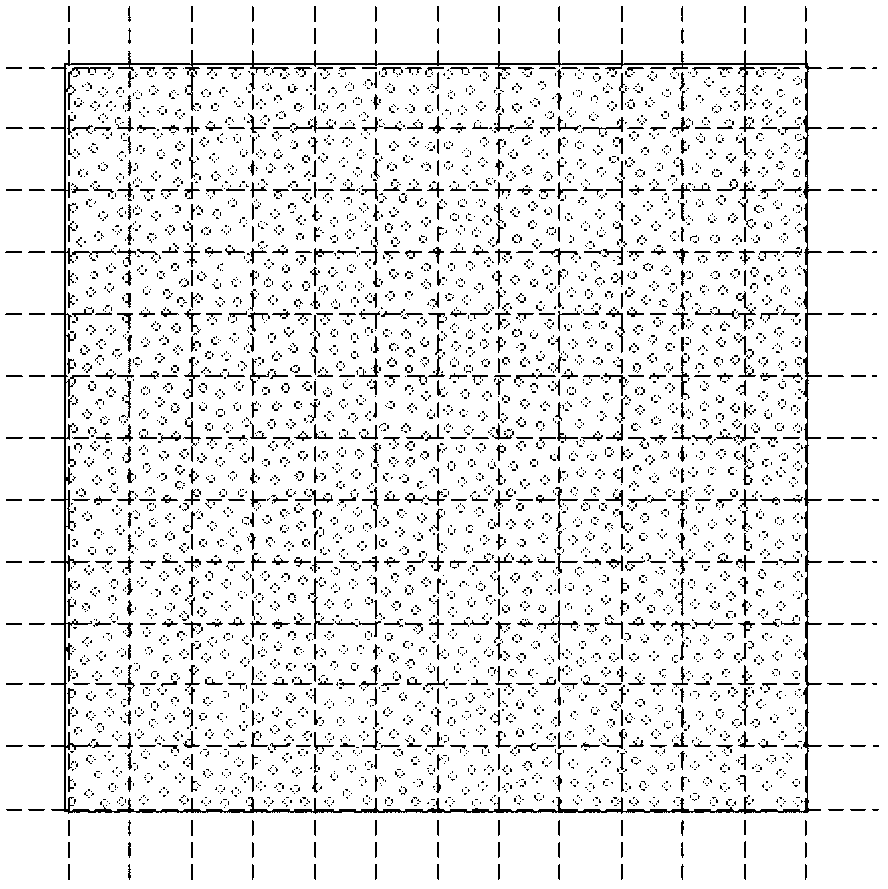

[0033] Such as Figure 1-6 As shown, a numerical simulation method for hydraulic splitting of the core wall of a rockfill dam, the steps are as follows:

[0034] (1) According to the indoor plane strain test, the stress-strain curve of the actual core wall soil material is obtained, and the biaxial numerical model of the granular discrete element is established;

[0035] (1.1) Take the core wall soil material of the actual project as a sample, conduct an indoor plane strain test on it, and draw the stress-strain curve;

[0036] (1.2) Establish a particle discrete element numerical model, obtain mesomechanical characteristic parameters (such as: particle size, stiffness, friction coefficient, bond strength, etc.) In order to ensure that the results of numerical simulation can have a certain guiding significance for actual engineering;

[0037] (2) According to the mesomechanical parameters determined by the particle discrete element biaxial test, the particle model of the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com