Straw field return no-tillage fertilization seeding machine

A seeder and straw technology, applied in the field of straw returning no-tillage and fertilizing seeders, can solve the problems of soil structure and soil microbial damage, the effect of straw returning to the field is not good enough, straw rots, heats up and burns seedlings, etc., and achieves rain-proof soil loss , The effect of increasing production is obvious, and the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

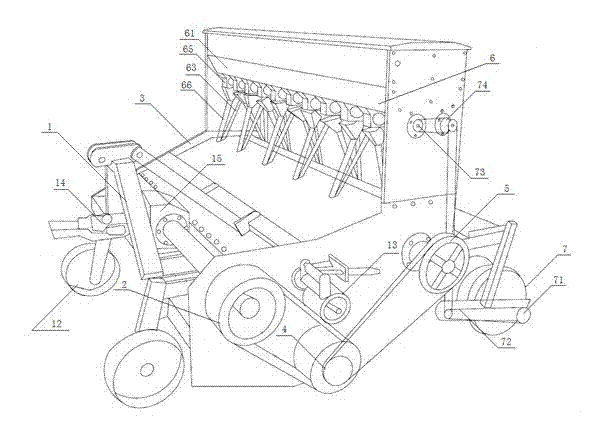

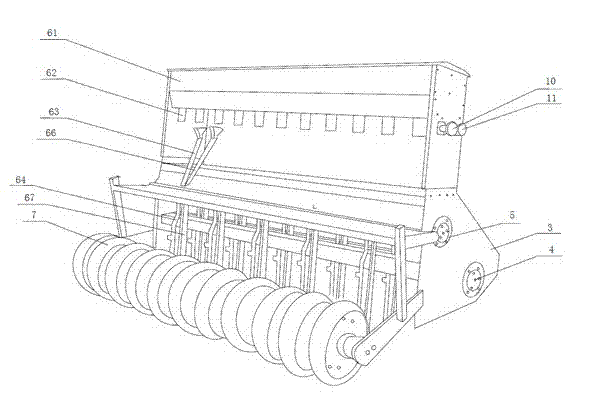

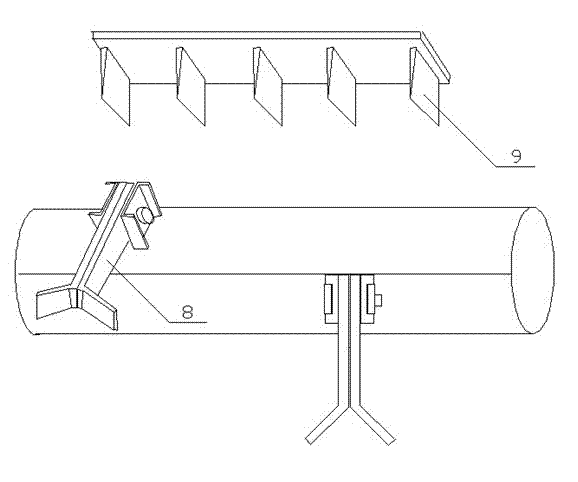

[0016] Such as figure 1 , 2 The straw returning no-tillage and fertilizing planter shown in 3 includes a suspension device 1, a transmission mechanism 2, a frame 3, a primary cutter shaft 4, a secondary cutter shaft 5, a pressing roller 7, and a fertilization and seeding assembly 6. Said suspension device 1 is installed on the frame 3, said speed change transmission mechanism 2 is installed on the frame 3, and is located below the suspension device 1; said first-stage cutter shaft 4 is installed in the inner chamber of frame 3, and its transmission shaft is connected with the speed changer The transmission mechanism 2 is connected, and a herringbone cutter 8 is arranged on the first-stage cutter shaft 4; the second-stage cutter shaft 5 is installed in the inner cavity of the frame 3, and is located at the rear stage of the first-stage cutter shaft 4, and its transmission shaft is connected to the variable-speed transmission Mechanism 2, a herringbone cutter 8 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com