Air-permeable masterbatch and fabrication method of air-permeable film with masterbatch

A technology of breathable masterbatch and breathable film, which is applied in the field of breathable masterbatch, can solve the problems of particle shedding of inorganic fillers, low controllability of micropore size, and high product defect rate, and achieves increased performance controllability and reduced tension. The effect of stretching process and reducing product defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

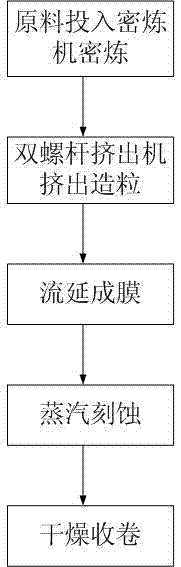

Method used

Image

Examples

Embodiment 1

[0025] Polyethylene 95%;

[0026] Ethylene glycol 5%;

[0027] Put polyethylene and ethylene glycol into the internal mixer and knead according to the above ratio. The temperature of the internal mixer is 150°C. After internal mixing for 5 minutes, the breathable masterbatch is obtained by extruding and granulating with a twin-screw extruder. The extruder The rotation speed is 30 rpm, and the temperature is 130°C, 140°C, 150°C, 150°C, 155°C, 160°C. Cast the prepared breathable masterbatch into a film, the temperature of the barrel of the casting machine is 250°C, the temperature of the die head is 260°C, and the linear speed of the casting machine is 85m / min, and the obtained cast film is cooled and finalized. roll. Pull the rolled cast film into a steam hot water tank for 2 minutes to dissolve the water-soluble organic matter in the film, and dry and roll the prepared water-proof and breathable film.

Embodiment 2

[0029] Polypropylene 95%;

[0030] Lactic acid 5%;

[0031] Put polypropylene and lactic acid into the internal mixer and knead according to the above ratio. The temperature of the internal mixer is 180°C. After internal mixing for 10 minutes, the air-permeable masterbatch is obtained by extruding and granulating with a twin-screw extruder. The extruder speed is 50 revolutions / minute, the temperature is 150°C, 160°C, 170°C, 165°C, 175°C, 180°C. The prepared breathable masterbatch is cast into a film, the barrel temperature of the cast machine is 260°C, the die head temperature is 280°C, and the linear speed of the cast machine is 95m / min, the cast film is cooled and finalized roll. The rolled cast film is pulled into a steam hot water tank for 5 minutes to dissolve the water-soluble organic matter in the film, and the prepared water-proof and breathable film is dried and rolled. Example 3

Embodiment 3

[0032] Polyethylene 90%;

[0033] Glycerol 10%;

[0034] Put polyethylene and glycerol into the internal mixer and knead according to the above ratio. The temperature of the internal mixer is 160°C. After 8 minutes of internal mixing, use a twin-screw extruder to extrude and granulate to obtain a breathable masterbatch. The extruder speed 40 rpm, temperature 130°C, 140°C, 150°C, 155°C, 160°C, 160°C. Cast the prepared breathable masterbatch into a film, the barrel temperature of the casting machine is 250°C, the die head temperature is 260°C, and the linear speed of the casting machine is 90m / min, and the obtained cast film is cooled and finalized. roll. The rolled cast film is pulled into a steam hot water tank for 3 minutes to dissolve the water-soluble organic matter in the film, and the prepared water-proof and breathable film is dried and rolled.

[0035] The properties of the water-proof and breathable membranes prepared in the above three examples are shown in the tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com