Polyolefin composition with high mechanical properties and preparation method thereof

A technology for mechanical properties and polyolefins, applied in the field of polyolefin compositions and their preparation, can solve the problems of impossible to achieve uniform distribution, affect the light transmittance of materials, and high mechanical properties, achieve low water vapor transmission rate, and improve rigidity. , the effect of good light transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

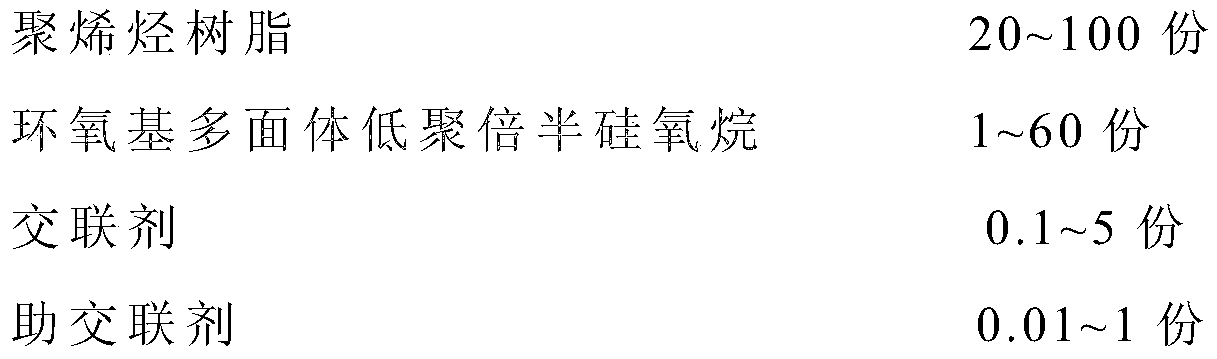

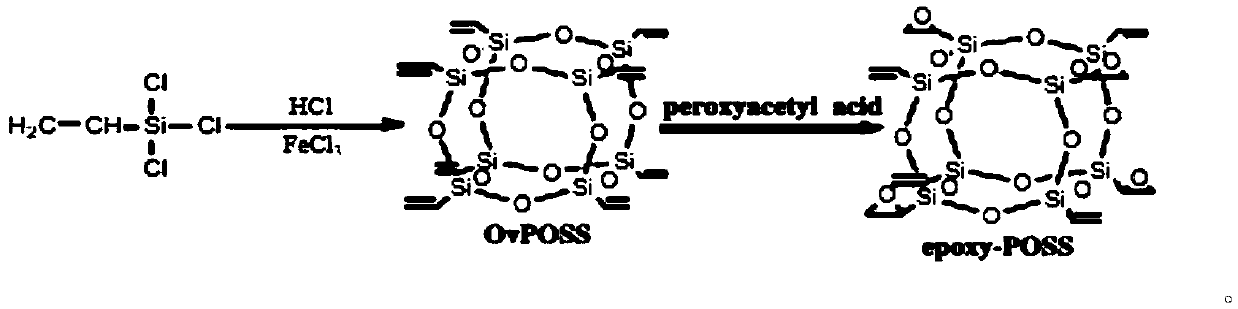

[0033] A polyolefin composition with high mechanical properties, the main steps are as follows:

[0034] Weigh 100g homopolypropylene, 10g epoxy-POSS, 0.5g 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 0.05g trimethylol propyl trimethacrylate Add the blender and stir for 30 minutes, then put the mixture into the hopper of the extruder. The temperature of each section of the extruder is between 150-200℃, the screw speed is 150r / min, and the melt is extruded and cooled in a water tank. , Towed to the pelletizer and dried after pelletizing.

Embodiment 2

[0036] A polyolefin composition with high mechanical properties, the main steps are as follows:

[0037] Weigh 100g homopolypropylene, 25g epoxy-POSS, 0.5g 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 0.05g trimethylol propyl trimethacrylate Add the blender and stir for 30 minutes, then put the mixture into the hopper of the extruder. The temperature of each section of the extruder is between 150-200℃, the screw speed is 150r / min, and the melt is extruded and cooled in a water tank. , Towed to the pelletizer and dried after pelletizing.

Embodiment 3

[0039] A polyolefin composition with high mechanical properties, the main steps are as follows:

[0040] Weigh 100g homopolypropylene, 40g epoxy-POSS, 0.5g 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 0.05g trimethylol propyl trimethacrylate Add the blender and stir for 30 minutes, then put the mixture into the hopper of the extruder. The temperature of each section of the extruder is between 150-200℃, the screw speed is 150r / min, and the melt is extruded and cooled in a water tank. , Towed to the pelletizer and dried after pelletizing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com