Method for machining and repairing surface of hydraulic rod through TLP

A hydraulic rod and diffusion welding technology, applied in metal processing equipment, welding media, manufacturing tools, etc., can solve the problems of low service life, low repair efficiency, electroplating environmental pollution, etc., and achieve long service life, shallow heating depth, and thermal impact small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiment (accompanying drawing).

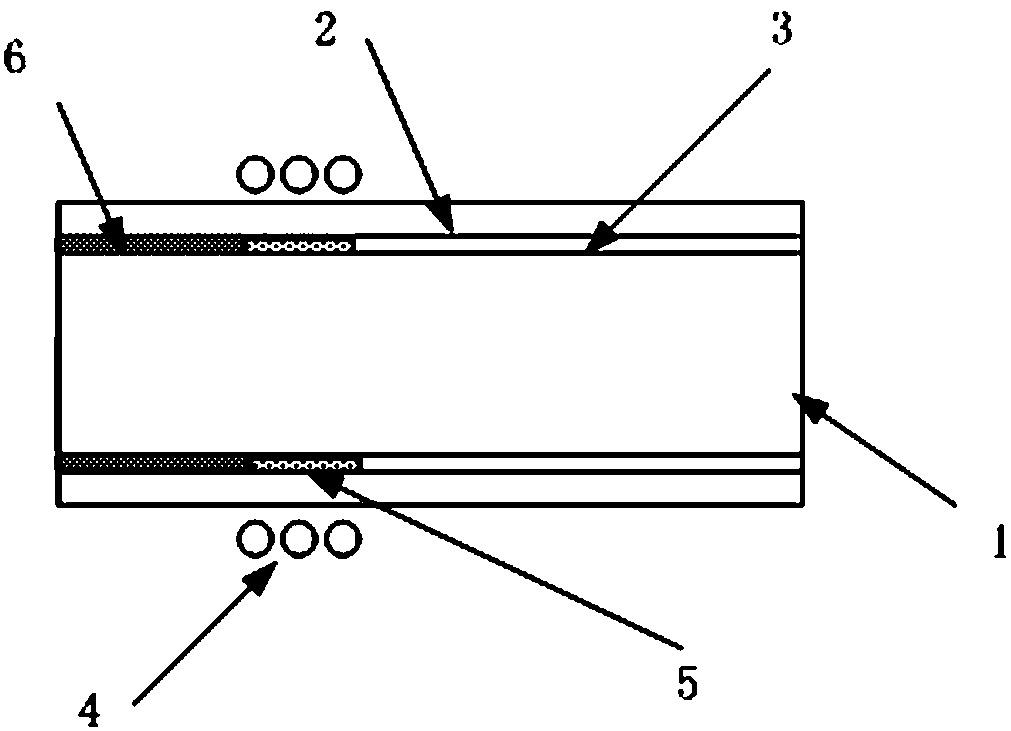

[0021] Such as figure 1 Shown, the method for TLP diffusion welding processing of the present invention and repair hydraulic rod surface comprises the following steps:

[0022] a. Carry out turning processing on the surface of the hydraulic rod 1 (unilateral turning to 0.5-0.9mm), to prepare for the surface connection of the stainless steel barrel 2;

[0023] b. According to the outer diameter of the hydraulic rod, cut out the stainless steel plate of the corresponding size, and prepare the corresponding stainless steel barrel through the bending equipment;

[0024] c. A layer of TLP diffusion bonded amorphous intermediate layer 3 is evenly wound on the surface of the hydraulic rod after turning; the TLP diffusion bonded amorphous intermediate layer is prepared from the following raw materials in mass percentage, wherein: Cr 8-10 %, Si 6-8%, B 5-6.50%, Fe25-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com