Method for manufacturing trunnion ring of large-size converter

A manufacturing method and technology of support rings, applied in the direction of manufacturing tools, welding equipment, workpiece clamping devices, etc., can solve the problems of low manufacturing accuracy, poor assembly accuracy, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

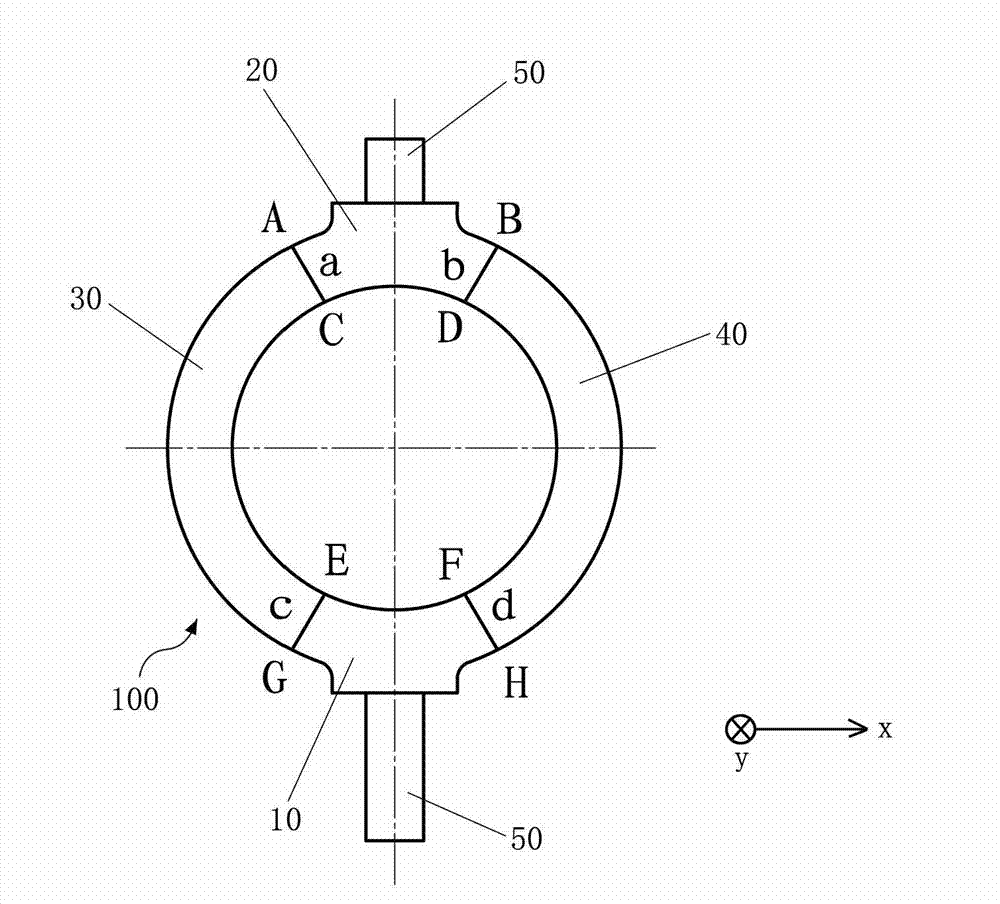

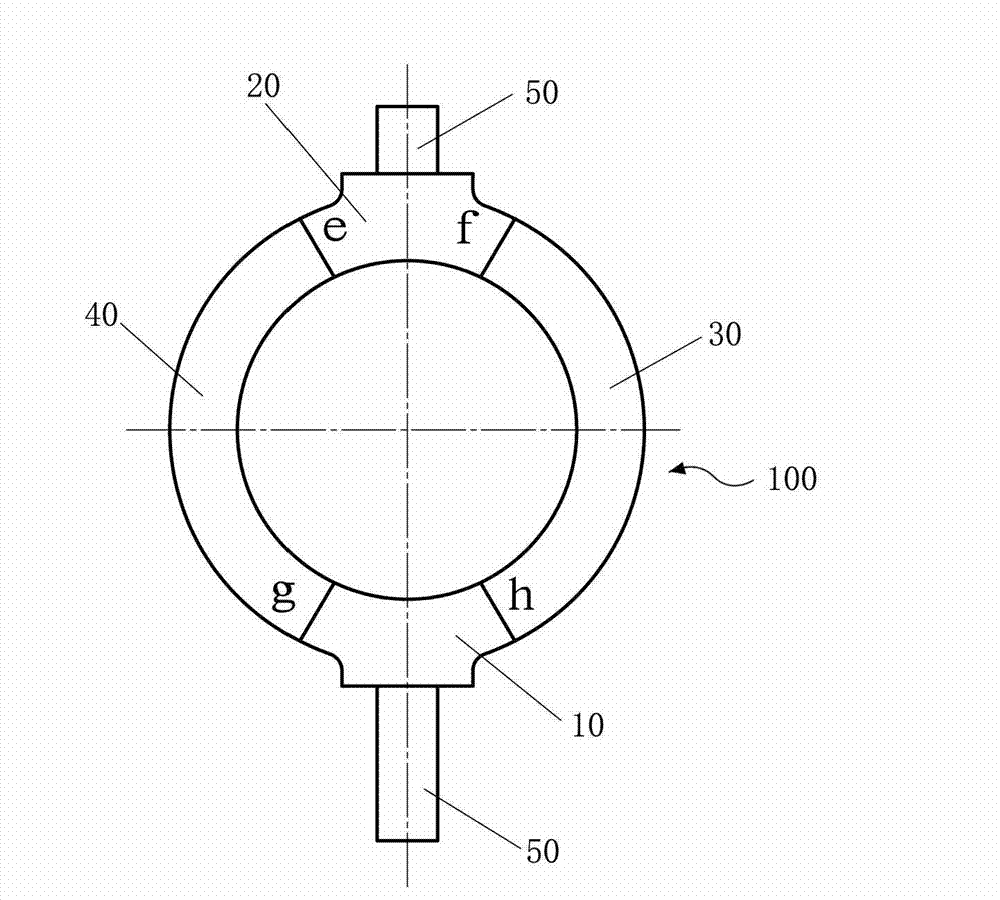

[0026] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0027] In general, the present invention aims at the shortcomings of the current large-scale converter support ring manufacturing process, and designs a support ring trunnion connection tool, and uses the laser collimator, an instrument for measuring coaxiality and flatness, to perform dynamic measurement. During the on-site welding process of the four parts of the support ring, the change of the coaxiality of the trunnion can be grasped at any time, so as to adjust the welding process, so as to ensure the coaxiality of the trunnion at within.

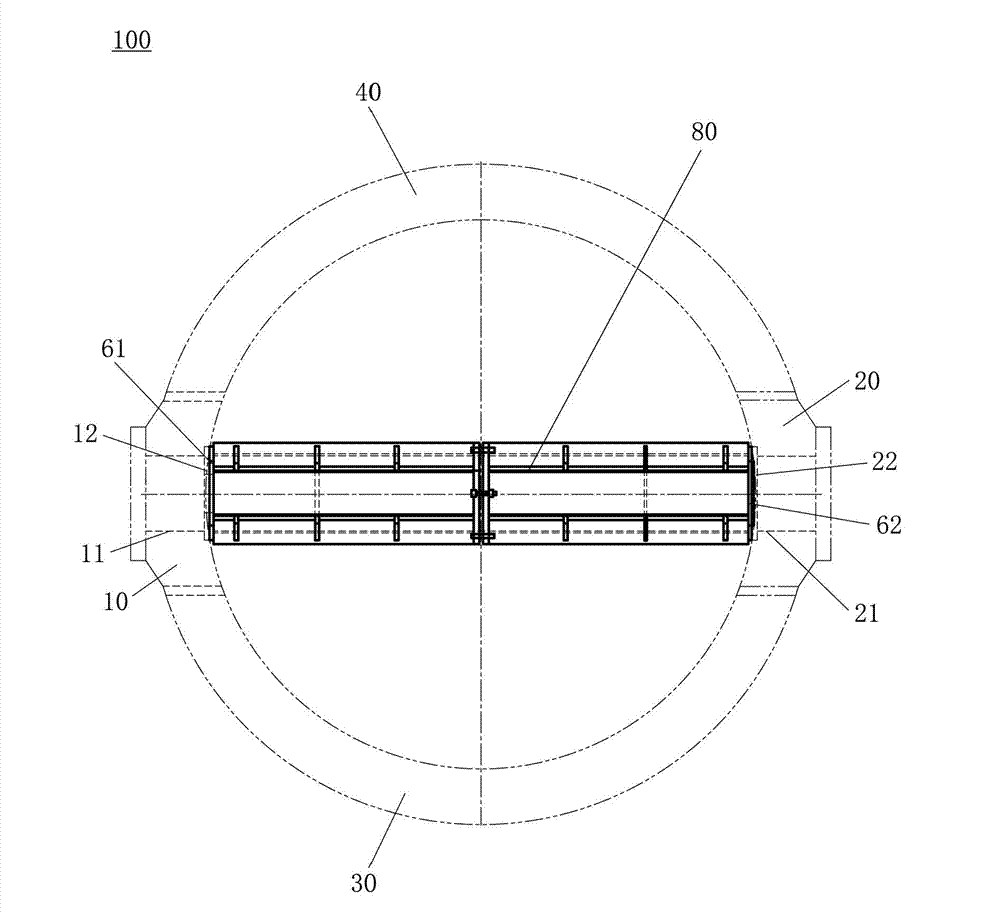

[0028] The following will combine figure 1 The pre-assembly process of the support ring 100 is described in detail.

[0029] The support ring 100 according to the embodiment of the present invention is manufactured into four parts, including the drive side trunnion seat 10, the non-drive side trunnion seat 20, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com