Concrete applicable to rear insertion cage and preparation method thereof

A technology for concrete and cage insertion, applied in the field of concrete slurry and its preparation, can solve the problems of excessive concrete slump loss, concrete pile body defects, and high production costs, achieve good workability, and improve compressive and pull-out resistance. The effect of bearing capacity and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

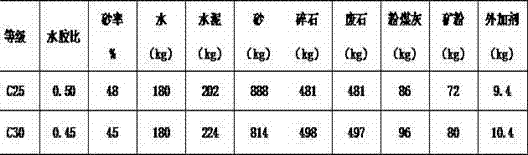

Examples

Embodiment Construction

[0032] In the selection of raw materials, the present invention has carried out a series of comparison tests on the performance of various raw materials, and preferably the following materials are used for preparing concrete.

[0033] , Cement: P.O42.5 cement, 3d compressive strength not less than 28.0MPa, 28d compressive strength not less than 50.0MPa.

[0034] , Sand: medium sand with a fineness modulus of 2.5-2.9, with a mud content of less than 3.0% and a mud content of less than 1.0%.

[0035] 1. Stones: continuously graded gravel with a nominal particle size of 5-16mm and continuously graded waste rock with a nominal particle size of 5-16mm, with a mud content of less than 1.0%, a mud content of less than 0.5%, and a needle flake content of no more than 15 %.

[0036] , Fly ash: Class II fly ash, the water demand ratio is not less than 95%, the fineness (0.045mm sieve residue) is not more than 25.0%, and the loss on ignition is not more than 8.0%.

[0037] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com