Motor-driven underground tractor for coiled tubing

A motor-driven, tractor technology, applied in the field of tractors, can solve the problems of large coiled tubing friction, difficulties in running in and taking out coiled tubing, etc., and achieve the effects of saving occupied space, not easy to turn over, and large speed control range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

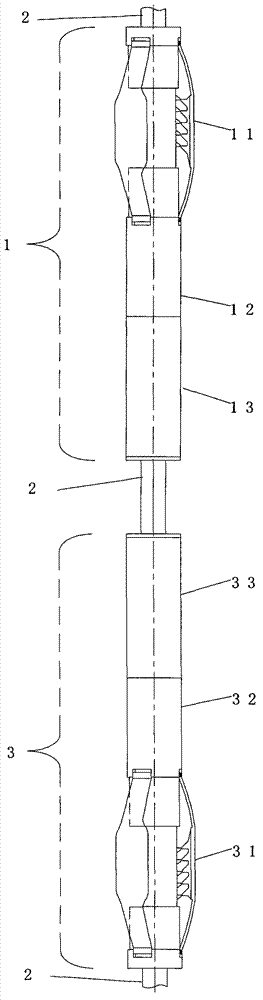

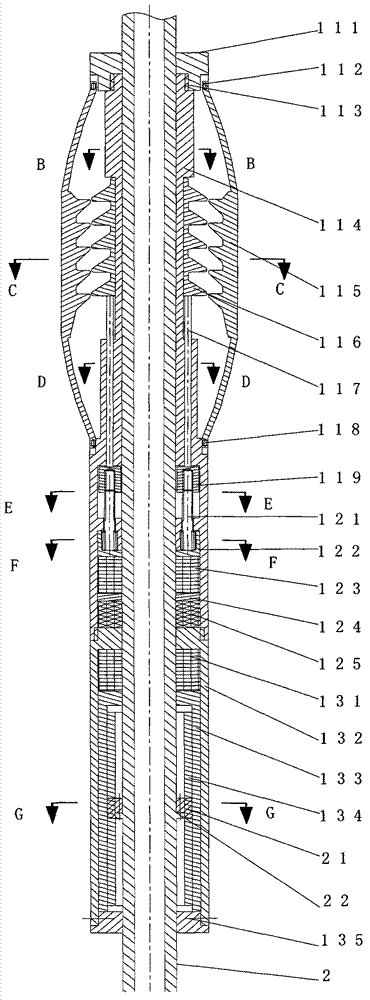

[0044] Such as Figure 1-2 As shown, the motor drives the coiled tubing downhole tractor, including the upper tractor system 1, the hexagonal center slide pipe 2, and the lower tractor system 3; upper and lower.

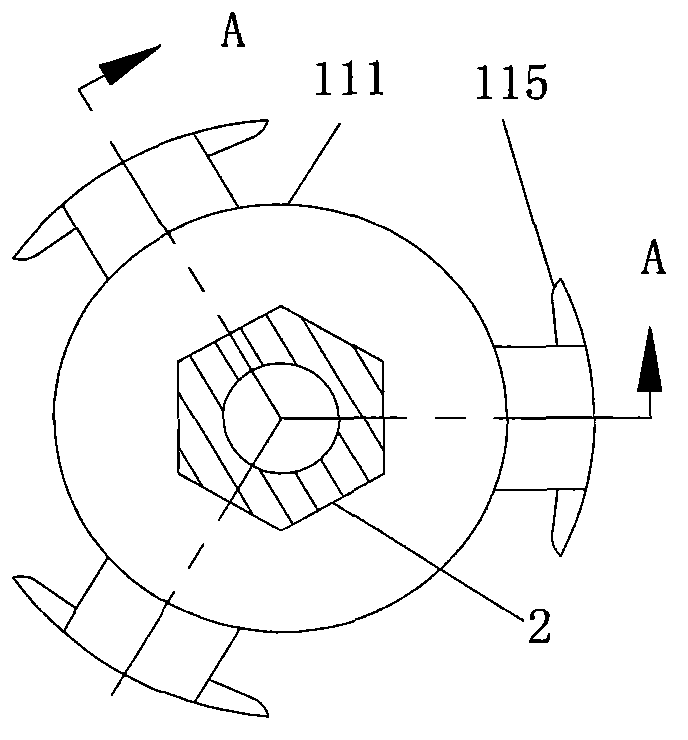

[0045] Such as figure 1As shown in -3, there is a hollow circular circulating water eye in the middle of the hexagonal center slide tube 2, and the outside is a regular hexagon. There are an upper protruding flange 22 and a lower protruding flange 24; the upper hexagonal center slide tube screw 21 and the lower hexagonal center slide tube screw 23 are respectively assembled on the upper protruding flange 22 and the lower protruding flange 24 by bolts; the hexagonal center slide tube 2 The upper end is connected to the downhole coiled tubing, and the lower end is connected to the bottom hole assembly.

[0046] Such as figure 1 As shown, the upper tractor system 1 includes an upper support unit 11 , an upper electric drive and control unit 12 and an upper traction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com