Method and equipment for assembling backlight module

A technology for assembling equipment and backlight modules, which is applied to lighting and heating equipment, optics, lighting devices, etc., can solve problems such as labor-intensive and time-consuming, and achieve the effects of improving efficiency, reducing labor costs, and reducing the number of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A detailed description will be given below in conjunction with the accompanying drawings and embodiments.

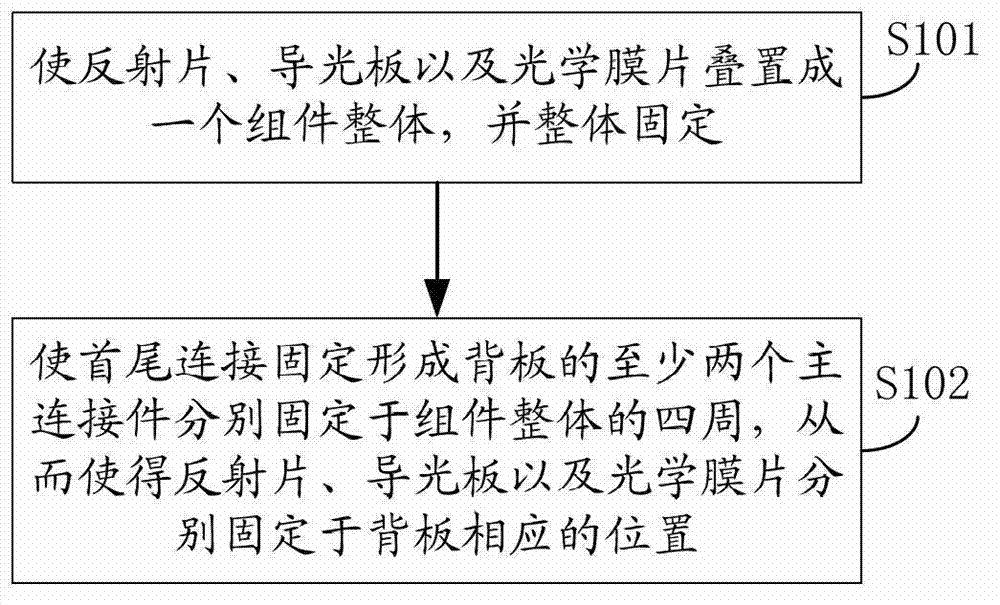

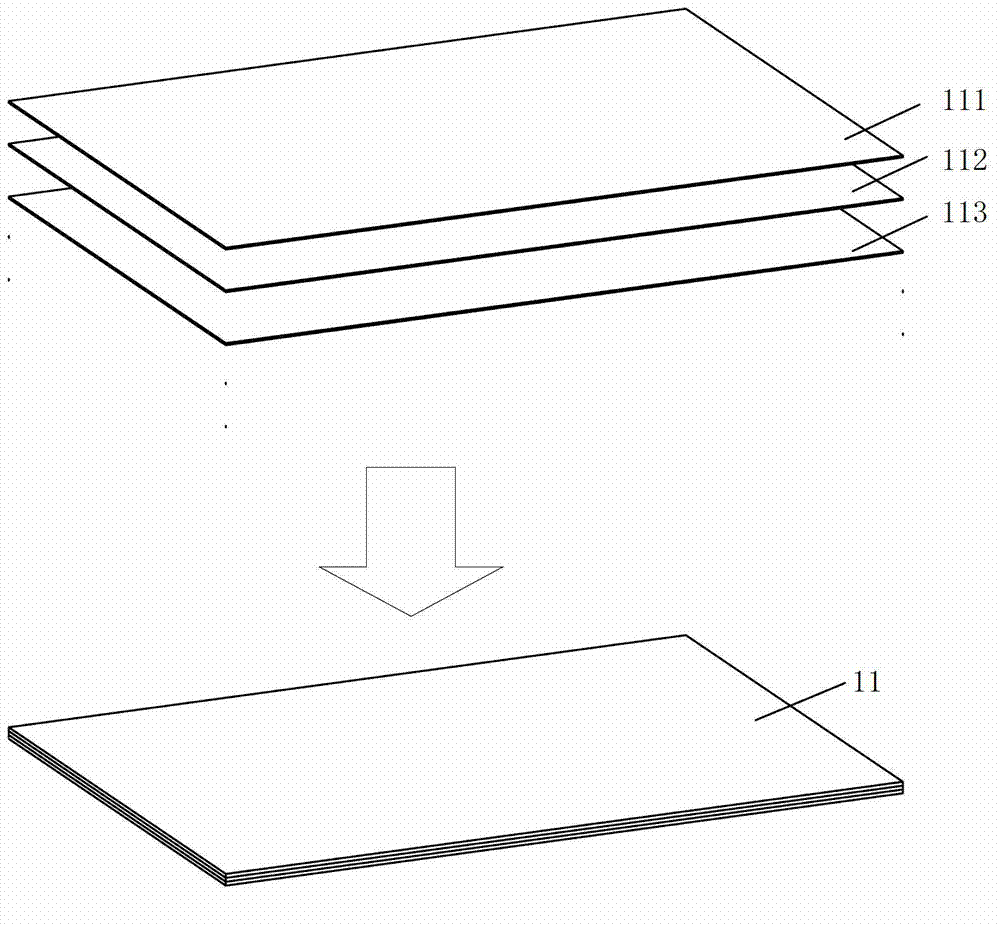

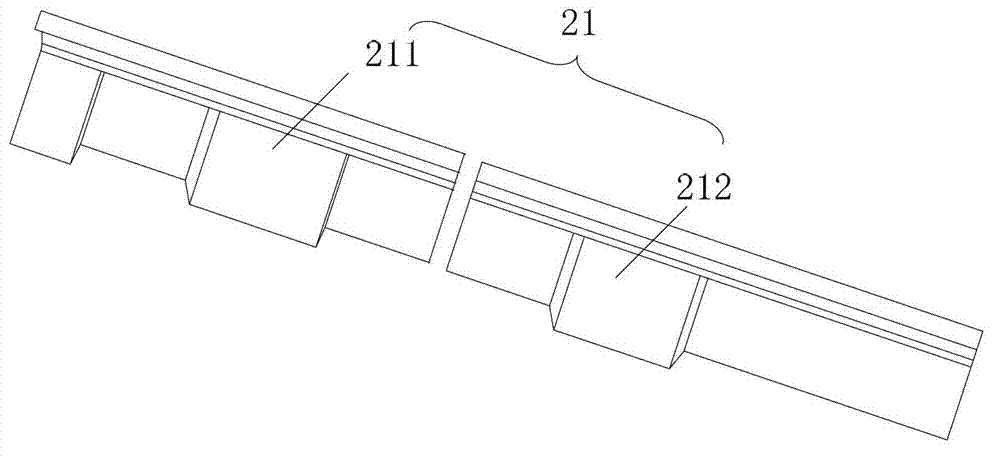

[0026] see figure 1 with figure 2 , figure 1 It is a flow chart of an embodiment of the assembly method of the backlight module of the present invention, figure 2 It is a schematic diagram of stacking the reflecting sheet, the light guide plate and the optical module in the embodiment of the assembly method of the backlight module of the present invention into a whole assembly. As shown, the method includes:

[0027] S101: stack the reflection sheet 113, the light guide plate 112 and the optical film 111 into a whole assembly 11, and fix it as a whole;

[0028] Among them, the fixing of the whole assembly 11 is realized by automation equipment, but the way of fixing the whole assembly 11 is not limited, as long as it does not affect the assembly of the backboard, in the embodiment of the present invention, one of the ways of fixing the whole assembly 11 is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com