Epoxy resin curing agent, epoxy resin composition, and adhesive agent for laminate

A technology of epoxy resin curing and epoxy resin, which is applied in the direction of epoxy resin glue, synthetic resin layered products, adhesive additives, etc., can solve the problems of insufficient adhesion of polyester, achieve improved gas barrier properties, Effect of high gas barrier property and good adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0144] Prepare 50 parts by weight of an epoxy resin (manufactured by Mitsubishi Gas Chemical Co., Ltd.; TETRAD-X) derived from m-xylylenediamine with a glycidyl amino group, 480 parts by weight of methanol, and 461 parts by weight of an epoxy resin curing agent. A solution of 69 parts by weight of ethyl acetate, and 0.1 part by weight of a silicone-based antifoaming agent (manufactured by BYK-Chemie GmbH; BYK065) was added thereto, and fully stirred to obtain a coating material solution (active amine hydrogen in curing agent A number / number of epoxy groups in epoxy resin = 7.24). An ethyl acetate solution (solid content concentration ; 30% by weight) as a polyurethane-based adhesive is applied to a biaxially stretched nylon film (manufactured by Toyobo Co., Ltd.; N1102) with a thickness of 15 μm, dried at 85°C for 10 seconds, and then attached with a nip roll. A stretched ester film (manufactured by Toyobo Co., Ltd.; E5200) with a thickness of 12 μm was combined and aged at 4...

Embodiment 2

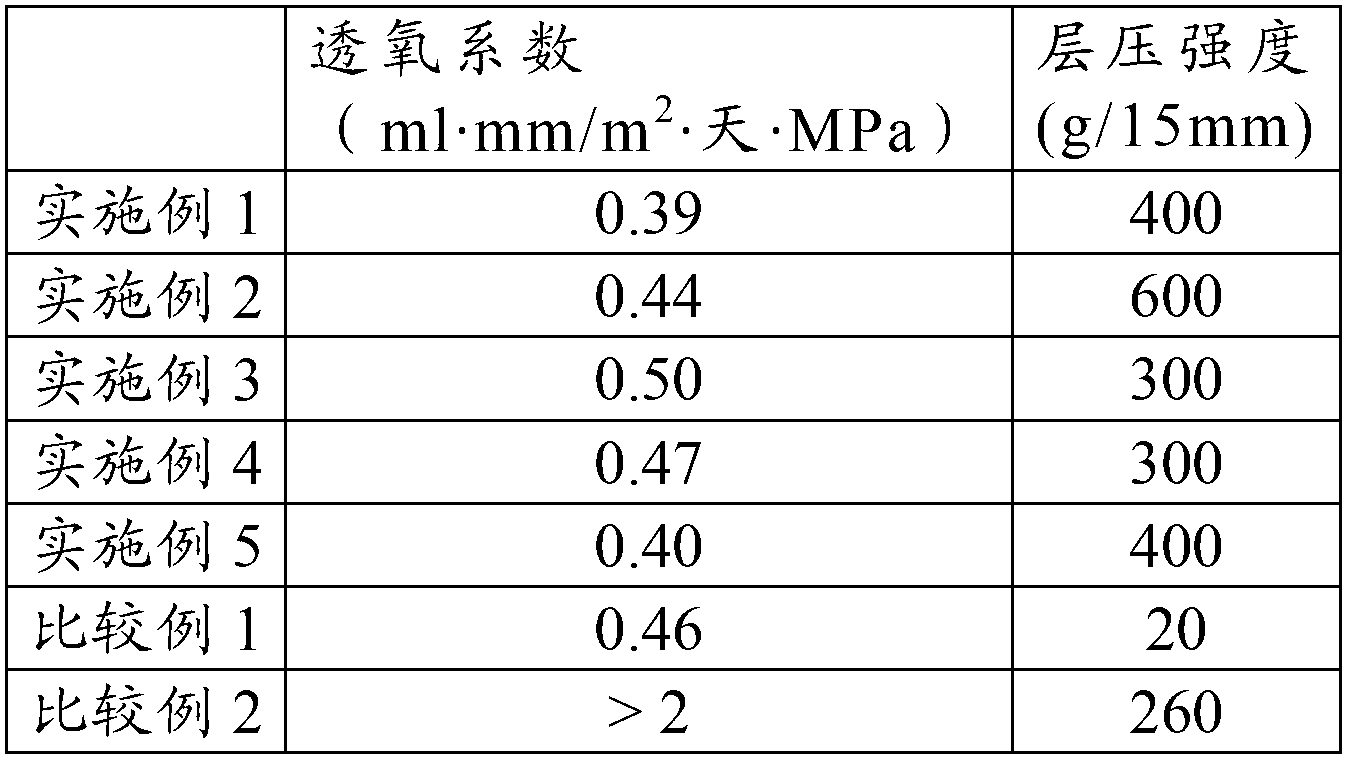

[0146] Except using 444 parts by weight of epoxy resin curing agent B instead of epoxy resin curing agent A, 454 parts by weight of methanol, and 66 parts by weight of ethyl acetate, it was produced by the same method as in Example 1. The active amine hydrogen number in the curing agent B / the epoxy group number in the epoxy resin is 7.33. The results are shown in Table 1.

Embodiment 3

[0148] It was produced by the same method as in Example 1 except that 851 parts by weight of epoxy resin curing agent C was used instead of epoxy resin curing agent A, methanol was 710 parts by weight, and ethyl acetate was 112 parts by weight. The active amine hydrogen number in the curing agent C / the epoxy group number in the epoxy resin is 12.22. The results are shown in Table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap