Method for preparing hydrocarbon-rich combustible gas through gasification of combustible solid waste

A solid waste and gas technology, applied in the production of combustible gas, granular/powder fuel gasification, sustainable manufacturing/processing, etc. problems, to achieve the effect of improving gas quality, solving serious losses, and saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

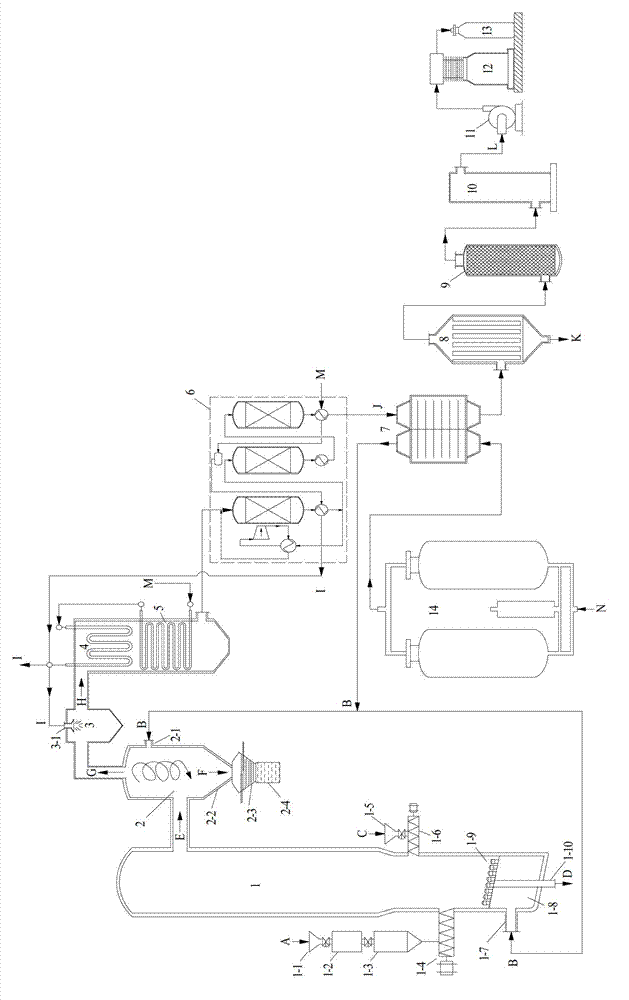

[0018] The present invention mainly consists of fluidized bed gasification reactor 1, cyclone melting furnace 2, steam reforming reactor 3, superheater 4, economizer 5, hydrocarbon synthesis reactor 6, heat pipe heat exchanger 7, bag dust removal It is composed of device 8, gas scrubber 9, dehydration tower 10, induced draft fan 11, compression device 12, gas storage tank 13, and air separation device 14.

[0019] The method for producing hydrocarbon-rich combustible gas by gasifying combustible solid waste of the present invention is as follows: the fluidized bed gasification reactor carries out low-temperature oxygen-enriched pressurized gasification of combustible solid waste, and the cyclone melting furnace carries out the secondary gasification of coke and tar. Pyrolysis and high-temperature melting of fly ash, and steam reforming of combustible gas to form hydrogen-rich gas. The superheater, economizer and heat pipe heat exchanger recycle the sensible heat of combustible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com