Construction method of extra-large diameter shield tunnel penetrating through urban overhead pile foundations in close range

A super-large-diameter, shield tunneling technology, which is applied in the direction of tunnels, infrastructure engineering, and foundation structure tests, can solve the problems of high traffic control costs, poor application, and large construction sites, and reduce soil mass. Disturbance, reduce the impact of traffic, and improve the effect of lateral displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

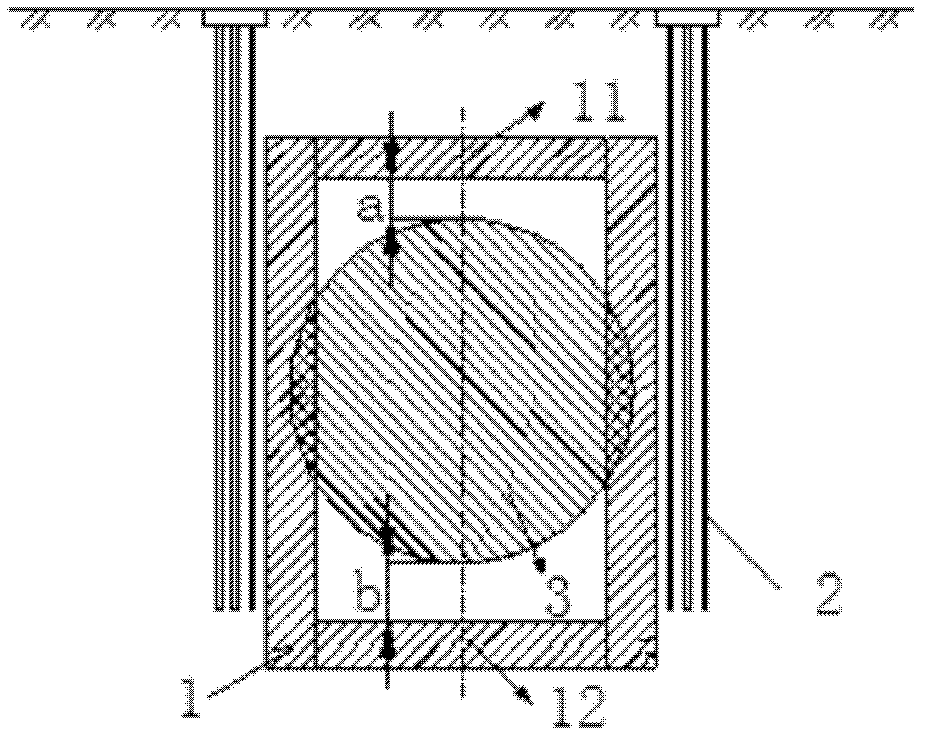

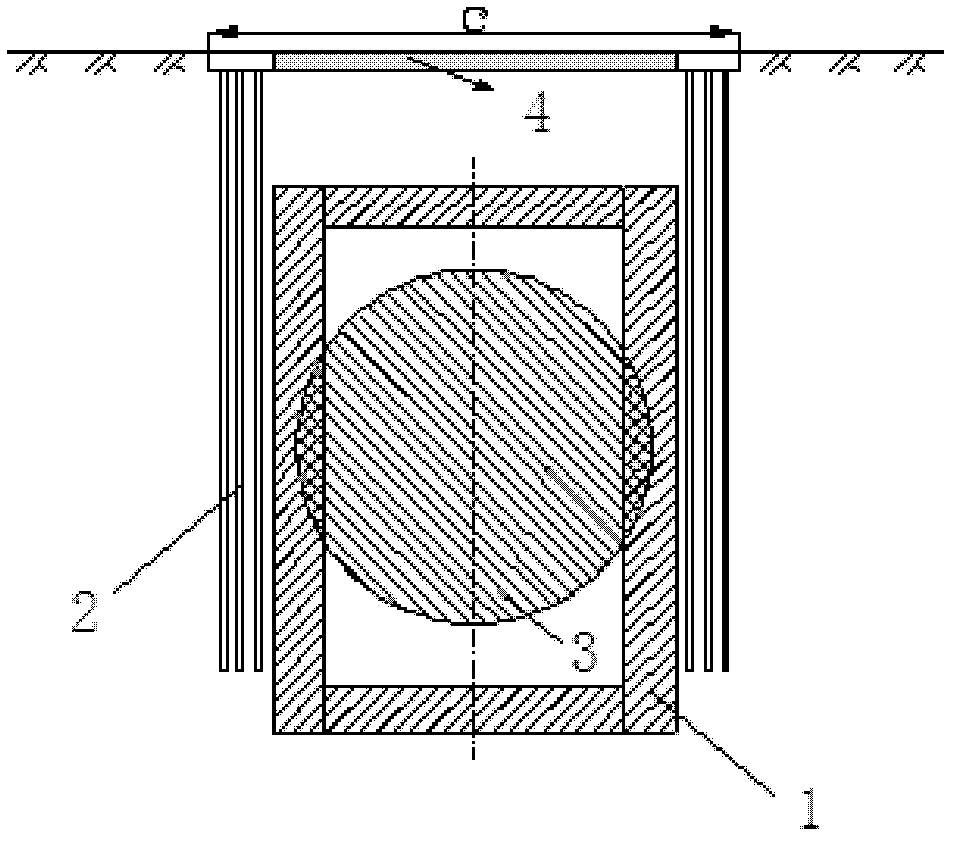

[0029] Such as Figure 1~2 As shown, the ultra-large diameter shield tunnel of the present invention passes through the pile foundation of the elevated pile foundation in the city at close range, including the method, mainly including the following construction procedures:

[0030] 1. "口"-shaped reinforcement of soil between pile foundations

[0031] Such as figure 1 Shown is a cross-sectional schematic diagram of a "mouth"-shaped reinforcement body 1 of the soil between pile foundations. A test section needs to be set up before crossing. It is required that the soil layer of the test section is distributed similarly to the crossing node. A row of single piles with the same specifications as the crossing node pile foundation are arranged on both sides of the tunnel advancement area of the test section. The inclinometer tube is preset in the hole. When the shield passes through the test section, the lateral displacement mode of the pile foundation is obtained by measuring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com