Electro-spinning device for preparing porous nano-fibre

A nanofiber, electrospinning technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of inability to prepare scaffolds, disorderly arrangement of nanofibers, unadjustable, etc., to ensure safety and accuracy. High degree and safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

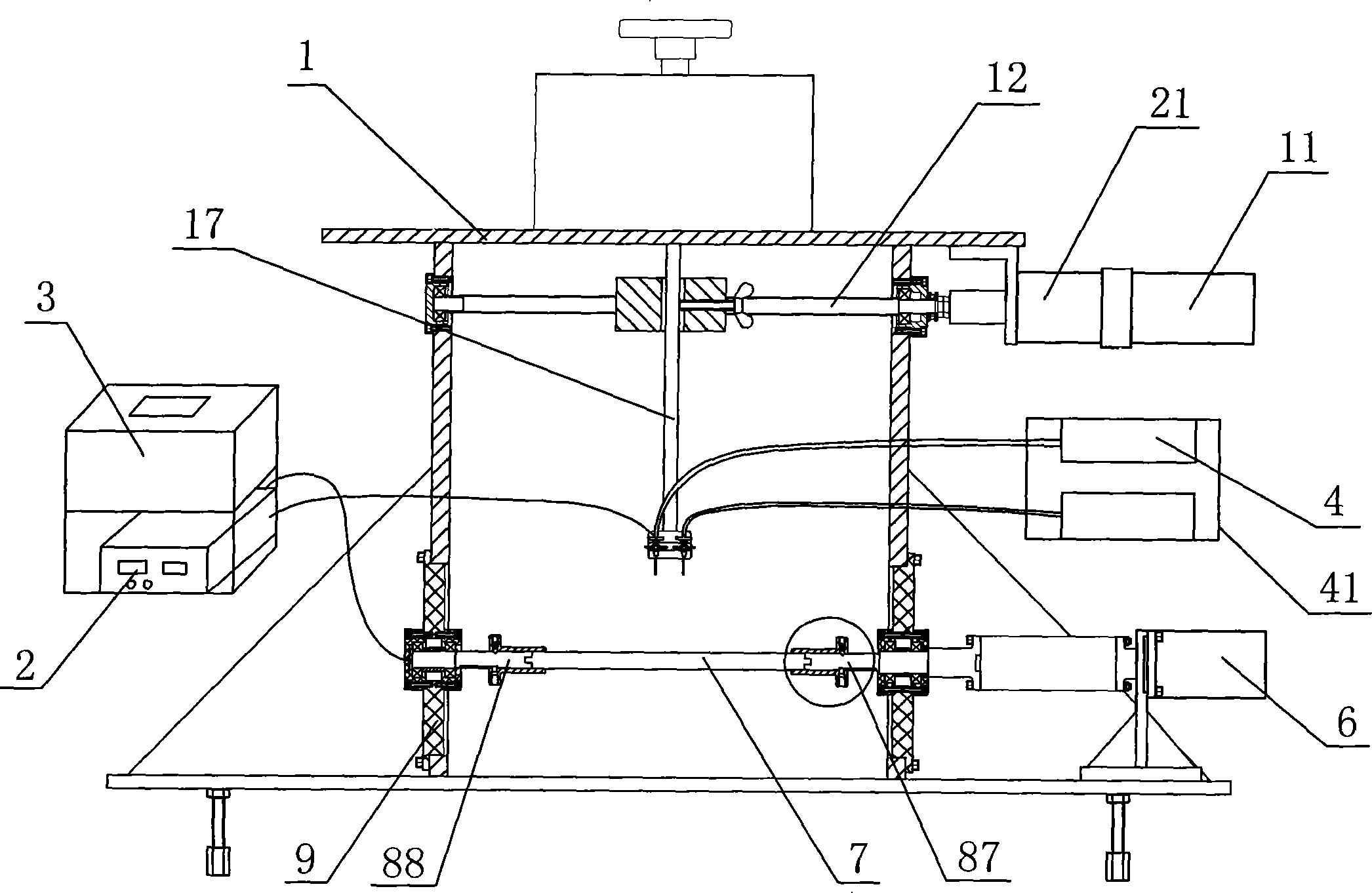

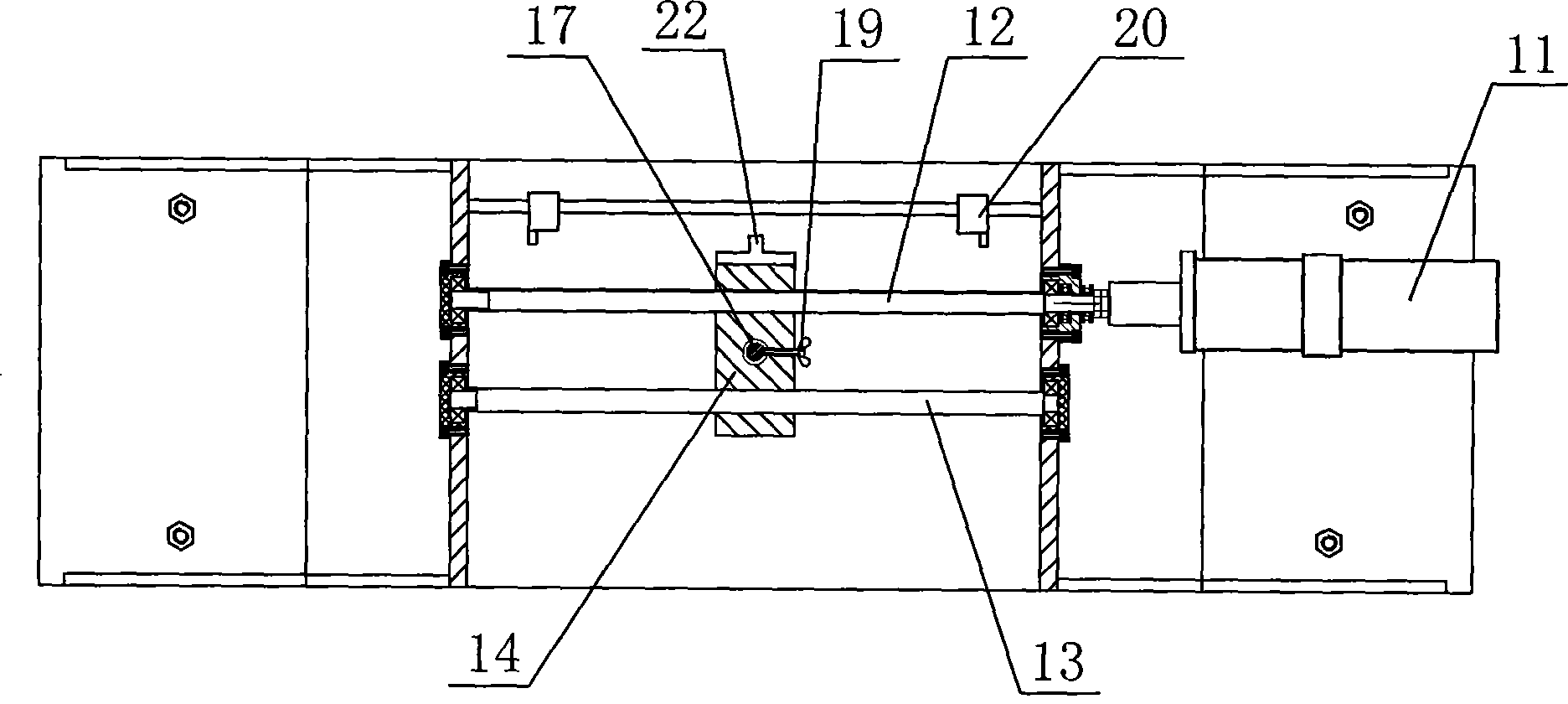

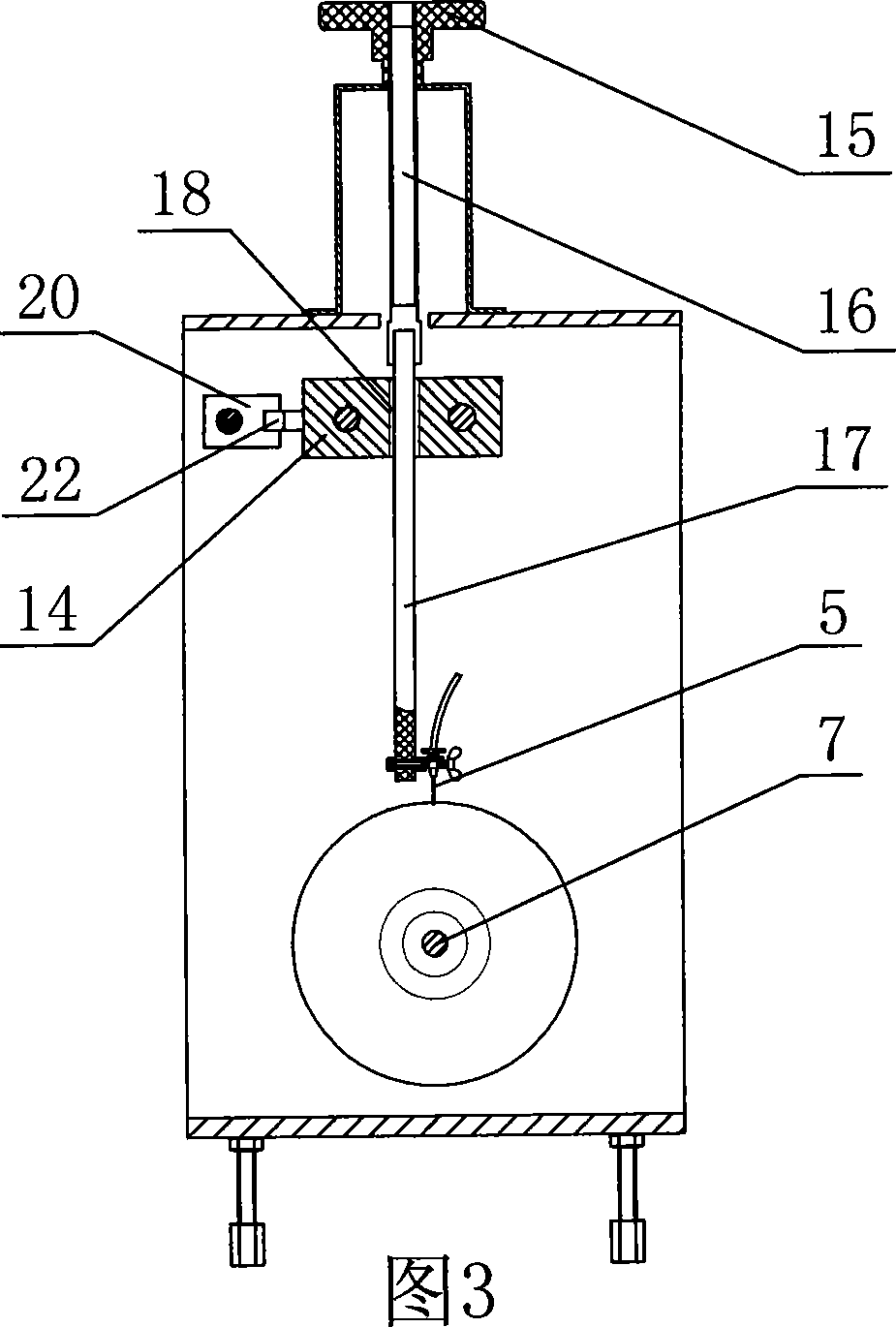

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] As shown in the figure, an electrospinning device for preparing a porous nanofiber scaffold includes a frame 1, an electrostatic high voltage generator 2, a central control system 3 and two liquid supply devices 4, and the liquid supply device 4 is arranged on an insulating In the frame 41, the frame 1 is fixedly provided with a first motor 11, the first motor 11 is connected with a reducer 21, the frame 1 is connected with a drive screw 12, and the drive screw 12 is fixedly connected with the reducer 21, The frame 1 is provided with a support rod 13 at the same level as the drive screw 12, the drive screw 12 is screwed with a connecting block 14 and at the same time the connection block 14 is slidingly fitted with the support rod 13, and the frame 1 is provided with an adjustment handwheel 15. An adjusting screw 16 is threadedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com