Goaf Filling Method of Hanging Reinforced Filling Body

A goaf and hanging technology, which is applied in the direction of filling, mining equipment, earth cube drilling and mining, etc., can solve the problems of insufficient strength of filling body, poor integrity of filling body, high filling cost, etc., and achieve saving of reinforcement materials and low cost , the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

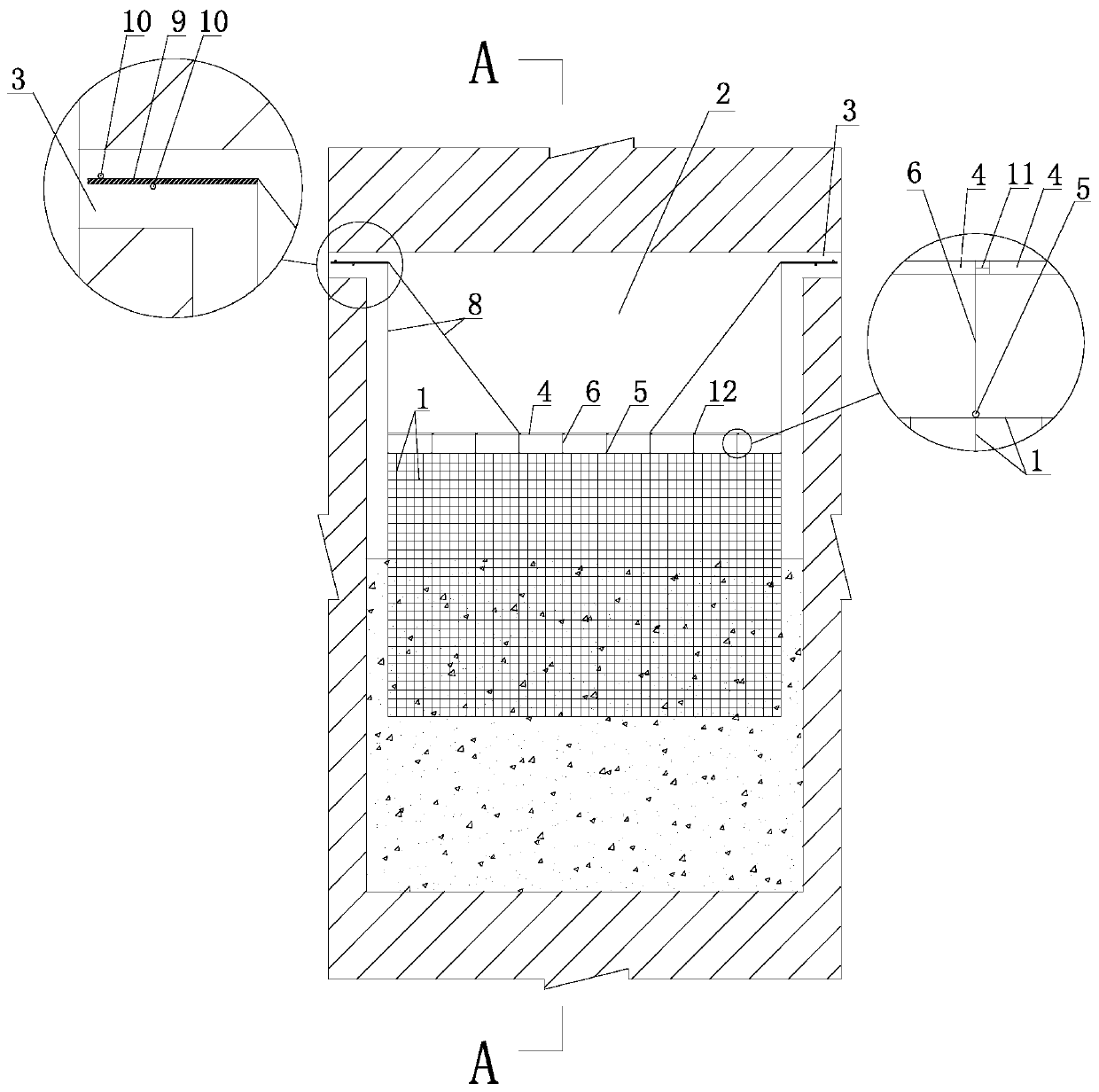

[0062] Such as figure 1 , figure 2 and image 3 As shown, the preferred embodiment of the present invention is a reinforcement method for embedding a three-dimensional flexible mesh in key positions of the filling body.

[0063] An iron ore adopts the stage filling method and two-step mining. The structural parameters of the ore block are: the height of the ore block is 100m, the width of the ore pillar is 20m, the width of the mine room is 25m, and the length of the ore block is 50m. The gob 2 is formed after mining the pillar and the pillar, and the pillar goaf 2 is filled, and then the mining of the pillars on both sides of the mine is completed, and the strength of the filling body meets the requirements of the mining process, and then returns to the mining house. , the two sides of the mine stope are the filling body of the pillar stope.

[0064] (1) Return the mining pillar to form the goaf 2.

[0065] (2) Determine the reinforcement reinforcement area of the fill...

Embodiment 2

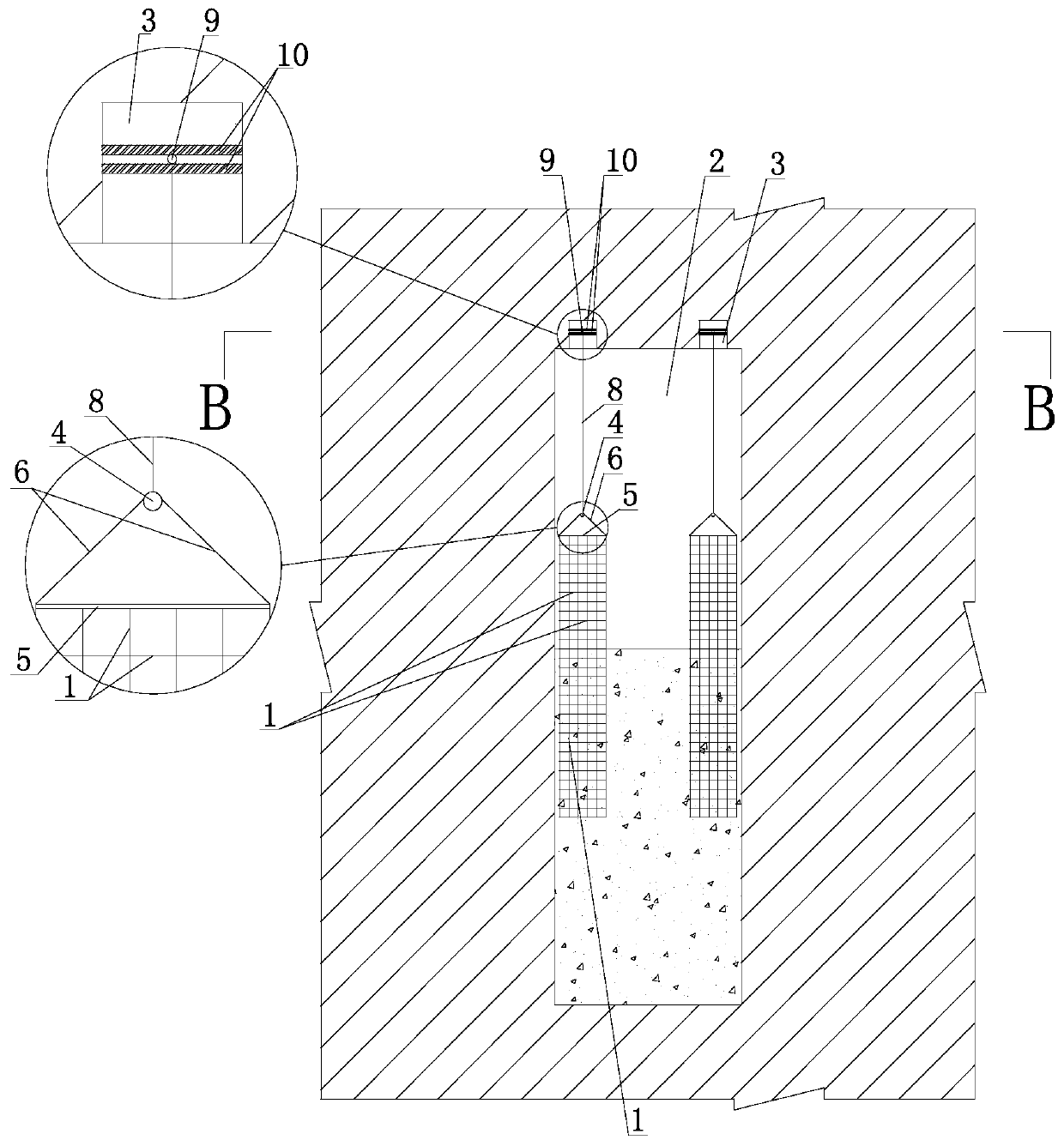

[0076] Such as Figure 4 As shown, the flexible net is suspended using cantilevered steel brackets.

[0077] The flexible net (flexible net cage 1) is installed:

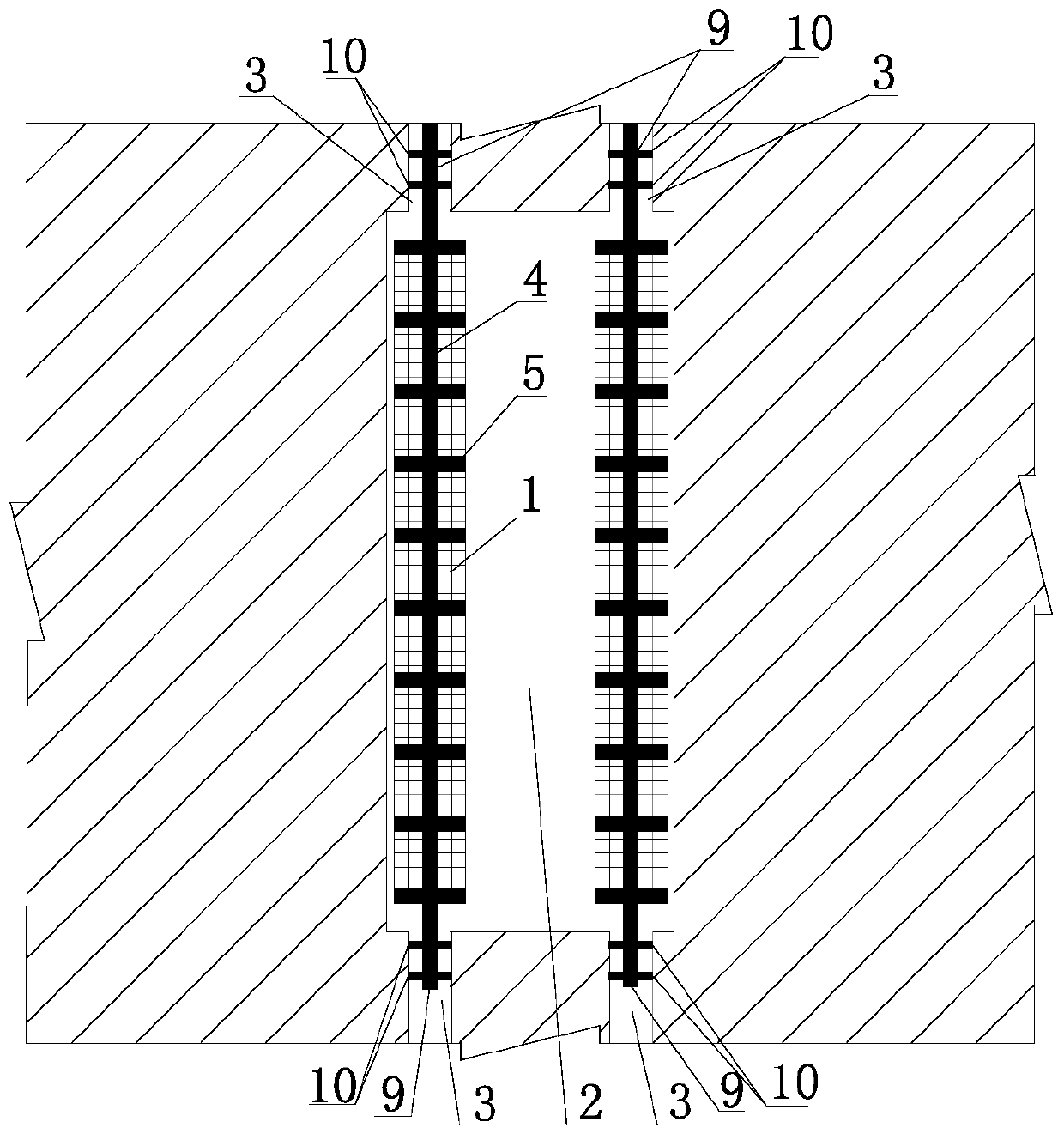

[0078] 1) Install the suspension steel wire rope support cantilever support (longitudinal support beam 9), the suspension steel wire rope support cantilever support (longitudinal support beam 9) is a rod system or truss that can be lengthened; the flexible net (flexible cage 1) is fixed on the flexible reinforced net On the suspension rod (strut bar 5), and bind the cross bar suspension rope (suspension rope unit 6) at the two ends of the flexible reinforced mesh suspension rod (strut shape bar 5), then adopt the rope clip to tie the cross bar suspension rope (suspension rope unit 6) Unit 6) is fixed on the fixed steel pipe (suspension fixed beam 4) of the suspension rope of the cross bar, and the fixed steel pipe (suspension fixed beam 4) of the suspension rope of the cross bar is 3m in every joint, and adopts qui...

Embodiment 3

[0086] The goaf filling method of hanging reinforced filling body, according to the mechanical analysis of the filling stope and the filling body, determines the reinforcement area, reinforcement method and shape of the flexible cage 1 of the filling body, and places the reinforcement in a fixed way. Into the filling stope to improve the tensile strength and shear strength of the filling body. A monitoring system is added to the flexible cage 1 of the filling body to monitor the stability of the filling body after filling. According to the actual situation of the filling stope and the filling body, a mechanical model for the filling stope and the filling body is established, and the mechanical analysis and / or numerical analysis are carried out to determine the tensile stress concentration area and the shear stress concentration area of the filling body. According to the stress magnitude of the tensile stress concentration area and the shear stress concentration area, the mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com