Blade pump with telescopic and controllable blades

A technology of vane telescopic and vane pumps, which is applied in the direction of pumps, rotary piston pumps, rotary piston machines, etc., can solve the problems that the rotation stability of the rotor cannot be guaranteed, affects the rotor transmission in the vane pump, and affects the service life of hydraulic oil, etc. Achieve the effect of maintaining the physical properties, reducing the connection structure and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

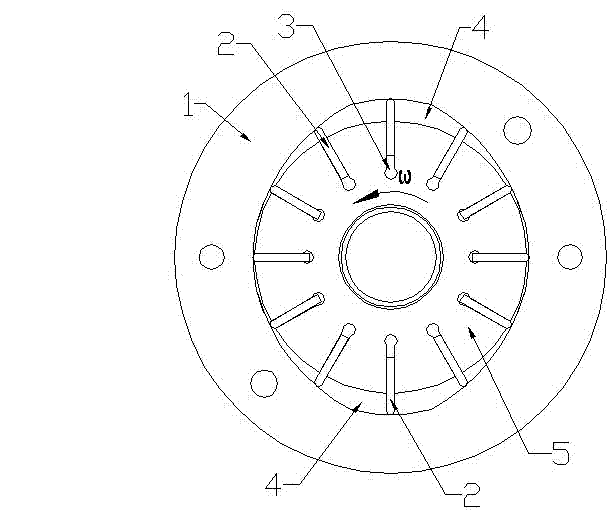

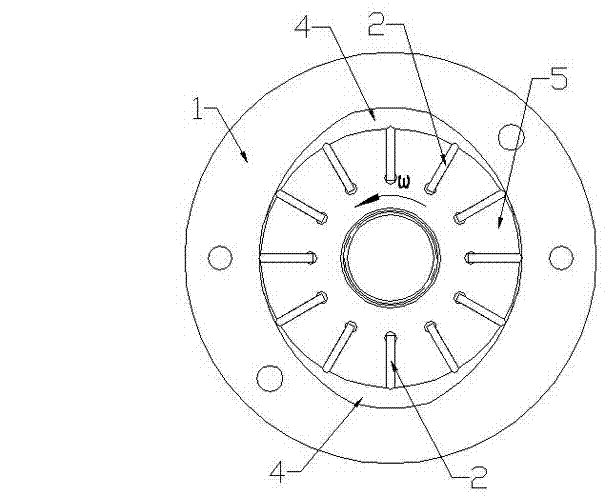

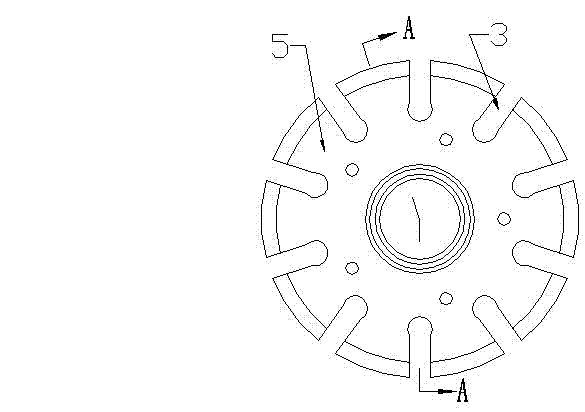

[0028]The structure of the vane pump with controllable vane stretching of the present invention includes a stator 1 and a rotor 5 , the rotor 5 is coaxially arranged in the stator 1 with gaps, and the rotor 5 can rotate in the stator 1 . The rotor 5 is provided with several vane slots 3 along its radial direction, and the openings of the vane slots 3 are located on the outer peripheral surface of the rotor 5 . Each vane slot 3 is provided with a vane 2 , and the dimension of the vane 2 along the axial direction of the rotor 5 is equal to or slightly smaller than the dimension of the vane slot 3 along the axial direction of the rotor 5 . When the rotor 5 rotates, the outer ends of the blades 2 can protrude to the outside of the rotor 5 under the action of centrifugal force. A cavity 4 is formed between the rotor 5 and the stator 1, and the inner wall of the stator 1 is similar to an ellipse. There are fluid suction area, fluid compression area and blade retraction area in the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap